Reaction kettle for polybenzimidazole fusion synthesis

A technology of polybenzimidazole and reaction chamber, applied in chemical/physical/physicochemical fixed reactors, chemical instruments and methods, feeding devices, etc., can solve problems of low controllability, incomplete foaming, and incomplete Complete and other problems, to achieve the effect of improving the uniformity of polymerization, uniform powder, and simple equipment manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

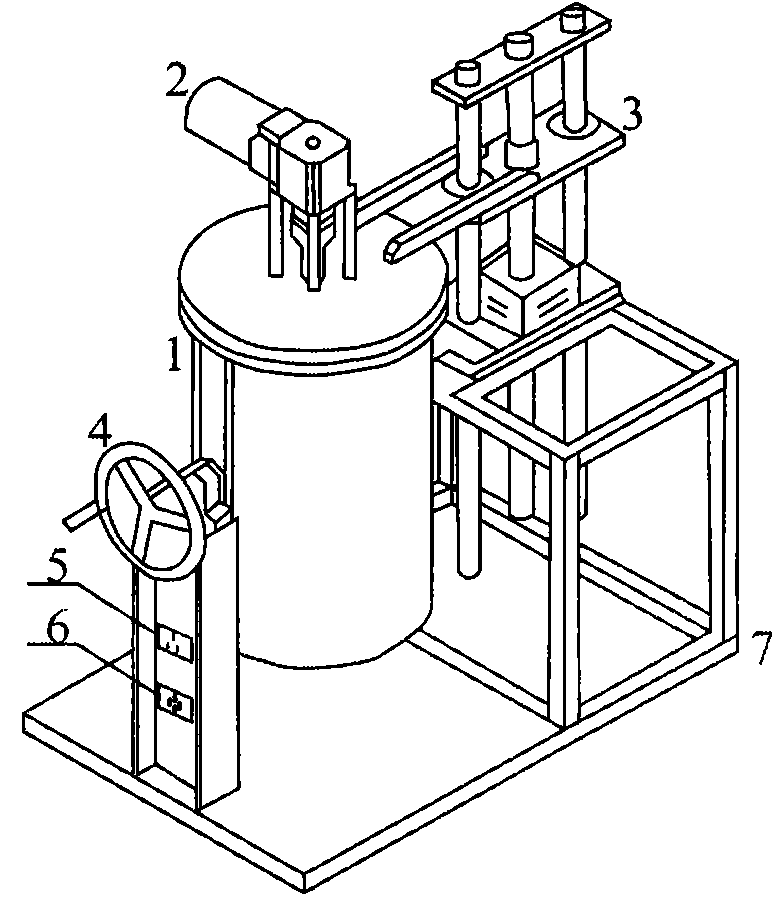

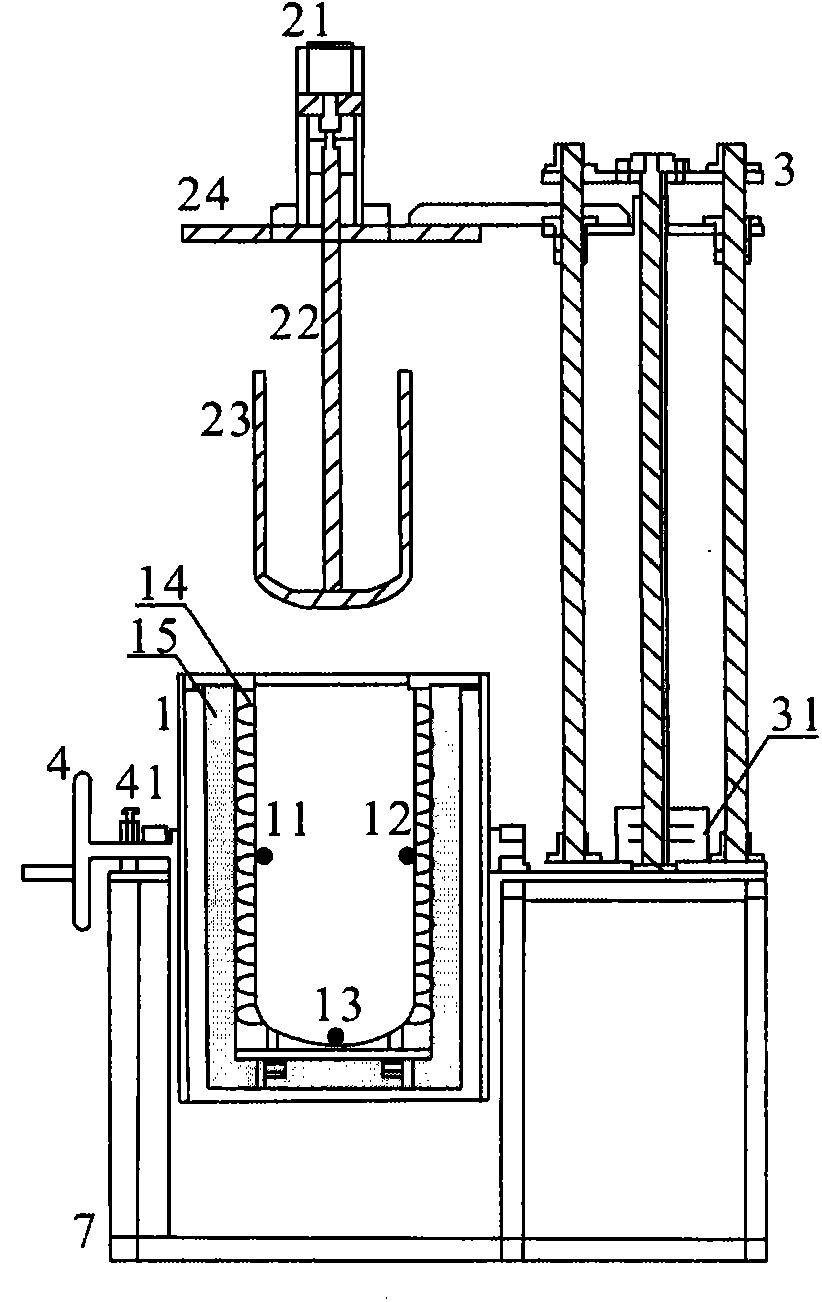

[0017] The reactor structural diagram of preparing PBI by melt polymerization method of the present invention is as follows figure 1 As mentioned above, the cross-sectional view in the X direction and the cross-sectional view in the Y direction are respectively as follows figure 2 with image 3 Described, it is characterized in that: the reaction still of preparing PBI is made of reaction chamber (1), stirring device (2), loam cake support (3), turning arm (4), power interface (5), control interface (6), And support (7) is formed. The structural block diagram of the electrical control system of the reactor is as follows: Figure 4 As shown, it is characterized in that: the total control module (8) is connected with three analog-to-digital conversion modules (81), (82), (83), and is connected with the input module (84), the power supply module (85) and the current control module (86) connected.

[0018] Generally, the reaction chamber (1) provides the required space and te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com