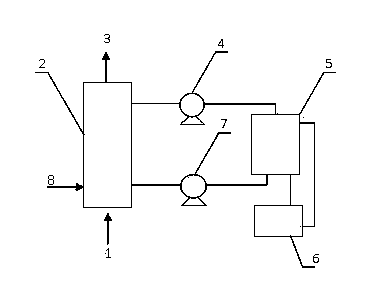

Oxidative desulphurization and brimstone recycling method

A technology for sulfur recovery and oxidative desulfurization, applied in chemical instruments and methods, separation methods, sulfur preparation/purification, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Removal of H 2 The reaction conditions at S are as follows: In the absorber: the temperature is 50°C, the reaction pressure is 0.6MPa, and the 2 The volume ratio of the hourly flow rate of S gas to complex iron desulfurization liquid is 15:1; in the mixer: the volume ratio of desulfurization liquid to oil phase (catalytically cracked diesel oil with a distillation range of 240~260°C) is 1:10, and the reaction The temperature is 60°C, and the reaction time is 50 minutes; in the solid-liquid separator: the temperature for cooling and separating sulfur is 10°C.

[0039]Composition of hydrogen sulfide-containing gas (volume): hydrogen sulfide content is 0.65%, SO 2 is 0.01%, COS is 0.01%; the concentration of Fe ions in the complex iron desulfurization solution is 0.06mol / L; after oxidative desulfurization of the desulfurization solution, the H in the gas is purified 2 S concentration is 15mg / m 3 , The purity of recovered sulfur is 98%.

Embodiment 2

[0041] Removal of H 2 The reaction conditions at S are as follows: In the absorber: the temperature is 60°C, the reaction pressure is 0.3MPa, and the 2 The volume ratio of the hourly flow rate of S gas to complex iron desulfurization liquid is 30:1; in the mixer: the volume ratio of desulfurization liquid to oil phase (catalytically cracked diesel oil with a distillation range of 260~300°C) is 1:5, and the reaction The temperature is 80°C, and the reaction time is 20 minutes; in the solid-liquid separator: the temperature for cooling and separating sulfur is 5°C.

[0042] Composition of hydrogen sulfide-containing gas (volume): hydrogen sulfide content is 0.18%, SO 2 is 0.1%, COS is 0.03%; the concentration of Fe ions in the complex iron desulfurization solution is 0.08mol / L; after oxidative desulfurization of the desulfurization solution, the H in the gas is purified 2 S concentration is 8mg / m 3 , The purity of recovered sulfur is 98.7%.

Embodiment 3

[0044] Removal of H 2 The reaction conditions at S are as follows: In the absorber: the temperature is 80°C, the reaction pressure is 0.1MPa, and the 2 The volume ratio of the hourly flow rate of S gas to complex iron desulfurization liquid is 1:8; in the mixer: the volume ratio of desulfurization liquid to oil phase (catalytically cracked diesel oil with a distillation range of 300~330°C) is 1:1, and the reaction The temperature is 100°C, and the reaction time is 10 minutes; in the solid-liquid separator: the temperature for cooling and separating sulfur is 15°C.

[0045] Composition of hydrogen sulfide-containing gas (volume): hydrogen sulfide content is 1.05%, SO 2 is 0.36%, COS is 0.27%; the concentration of Fe ions in complex iron desulfurization solution is 0.1mol / L; after oxidative desulfurization of desulfurization solution, the H in the gas is purified 2 S concentration is 10mg / m 3 , The purity of recovered sulfur is 98.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com