Aging-resistant starch gelatinizing type bread mix, starch gelatinizing type bread and manufacturing method thereof

A kind of ready-mixed flour and anti-aging technology, which can be used in the processing of dough, pre-baked dough, baking, etc. It can solve the problems of poor bread elasticity and unsatisfactory anti-aging effect, so as to delay aging and improve the ability of locking water and moisturizing. , the effect of enhancing water holding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: Using the Chinese seed method to make mellow cooked bread

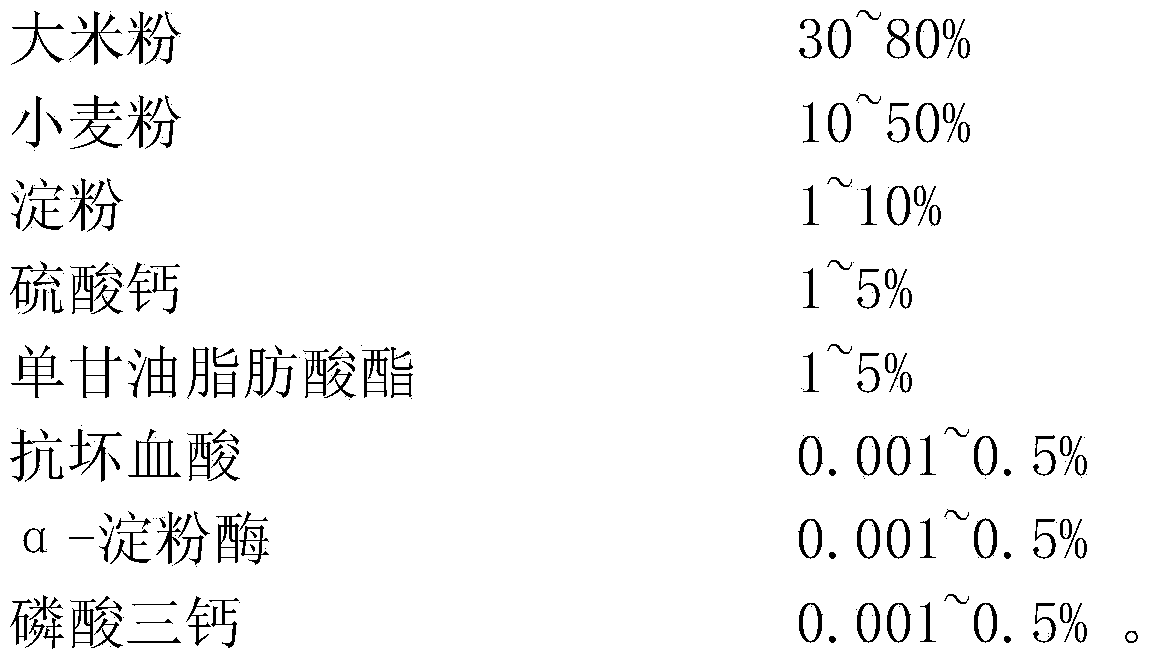

[0024] (1) Sieve 96 grams of water-milled rice flour, 96 grams of all-purpose flour, and 24 grams of wheat starch, respectively, and mix with 11.0 grams of calcium sulfate, 11.0 grams of monoglyceride fatty acid ester, 0.6 grams of ascorbic acid, 0.7 grams of α-amylase, and triphosphate Calcium 0.7 g mixed, stirred evenly, to obtain 240 g of alcohol-cooked bread premix;

[0025] (2) Put the mellow cooked bread pre-mix powder obtained in step 1 into the mixing tank, weigh 240 grams of freshly boiled water, quickly pour it into the mixing tank, and stir at a low speed for about 1 minute, the pre-mix powder is basically mixed, and the dough is formed Put the hot pre-mixed powder dough into a basin, cover with plastic wrap, put it in a refrigerator at 2-4°C, and refrigerate overnight for later use.

[0026] (3) To make medium-sized dough, weigh 1500 grams of high-gluten flour and 90 grams of fresh ye...

Embodiment 2

[0041]Embodiment 2: Adopt fast method to make mellow cooked bread

[0042] (1) Sieve 100 grams of puffed rice flour, 80 grams of all-purpose flour, and 10 grams of wheat starch, respectively, and mix with 4.4 grams of calcium sulfate, 4.4 grams of monoglyceride fatty acid ester, 0.4 grams of ascorbic acid, 0.4 grams of α-amylase, and triphosphate Calcium 0.4 g mixed, stirred evenly, to obtain 200 g of alcohol-cooked bread premix;

[0043] (2) Put the mellow cooked bread premix powder obtained in step 1 into a mixing tank, weigh 200 grams of freshly boiled water, quickly pour it into the mixing tank, and stir at a low speed for about 1 minute, until the premix powder is basically stirred evenly, and the dough becomes Put the hot pre-mixed powder dough into a basin, cover with plastic wrap, put it in a refrigerator at 2-4°C, and refrigerate overnight for later use.

[0044] (3) Beat the dough and weigh the following raw materials: 3000 grams of high-gluten flour, 240 grams of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com