Servo system contour control method based on task polar coordinate system

A technology of polar coordinate system and servo system, applied in the field of contour control of servo system based on task polar coordinate system, can solve the problem of large contour error and achieve the effect of reducing contour error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

[0030] A servo system contour control method based on a task polar coordinate system, comprising the following steps:

[0031] S1, establish the dynamic equation of the XY motion platform;

[0032] S2. According to the expected trajectory information, establish the task polar coordinate system based on the approximation of the close circle, and calculate the corresponding coordinate transformation relationship;

[0033] S3. Convert the system dynamics equation in the Cartesian coordinate system into the error dynamics equation in the task polar coordinate system;

[0034] S4. Design a feedback PD controller based on feedforward compensation to realize decoupling control of error dynamics.

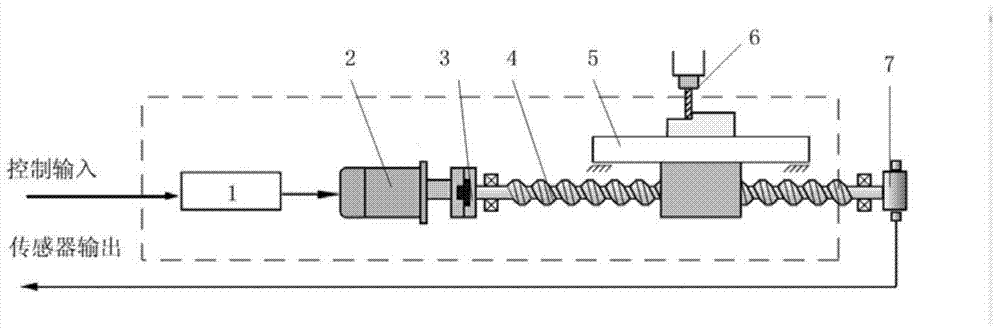

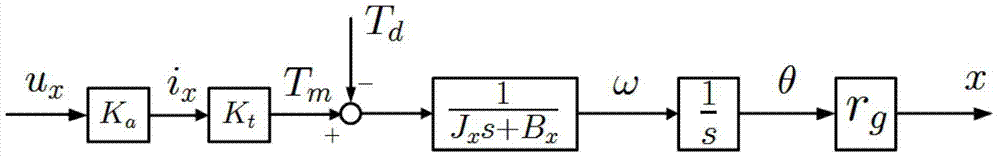

[0035] The specific implementation method of step S1 "establishing the dynamic equation" is as follows:

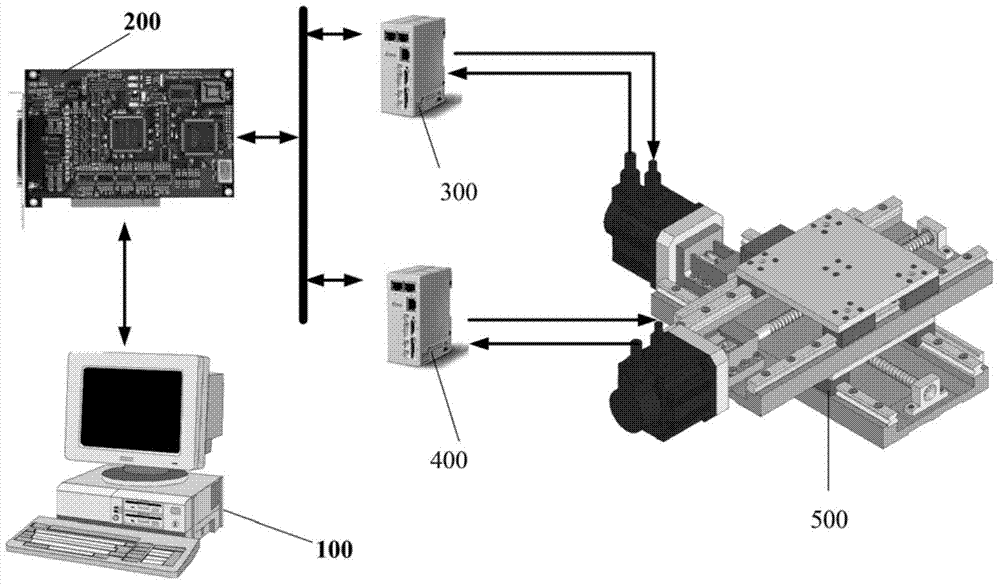

[0036] like Figure 1 to Figure 7 As shown, in o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com