Method for paving HDPE (high-density polyethylene) geomembranes in refuse landfill

A technology of landfill and laying method, which is applied in infrastructure engineering, protection devices, buildings, etc., can solve the problems of high construction cost, high maintenance cost, fracture of welds, etc., and achieves low maintenance cost, reduced maintenance frequency, Welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the drawings.

[0017] 1. Cut and lap, cut HDPE geomembrane, and lap in and around the reservoir area;

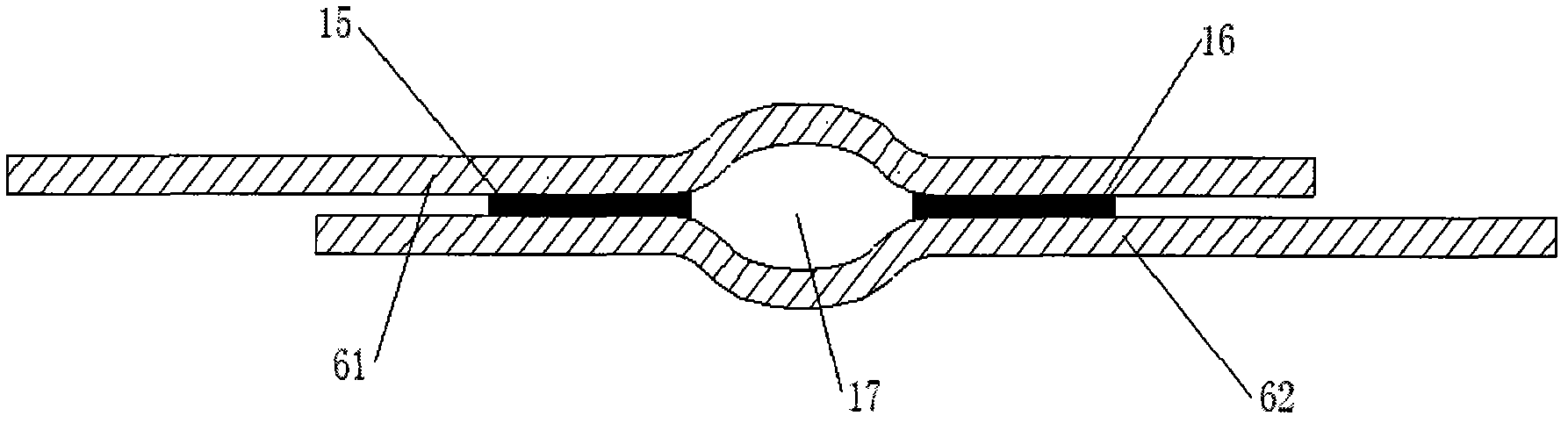

[0018] 2. Hot melt welding, such as figure 1 , Is a schematic diagram of laying and welding HDPE geomembrane in the landfill of the present invention, the HDPE geomembrane upper piece 61 and the lower piece 62 are overlapped, and compressed air is blown between the overlapped upper and lower pieces to form a compressed air channel 17 , Welding seams 15 and 16 are formed on the left and right sides of the compressed air channel, and the two pieces of HDPE geomembrane are hot-melted. The hot-melting temperature is maintained at 100-150℃. Weld with 16 places, the welding temperature is 450-480℃;

[0019] 3. Inspection and repair, check the HDPE geomembrane after the hot melt welding is completed, check the damage of the HDPE geomembrane laid, if the damage is greater than 10% of the width of each HDPE ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com