Method for cleaning rubbish through retraction swinging type rubbish cleaning device

A technology of garbage cleaning and rotating shaft, applied in the application, carpet cleaning, floor cleaning and other directions, can solve the problems of easy to slip through the brooms on both sides, waste of resources, ineffective cleaning of garbage, etc., to achieve easy replacement of parts, high efficiency The effect of clearing leaves and large-scale cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

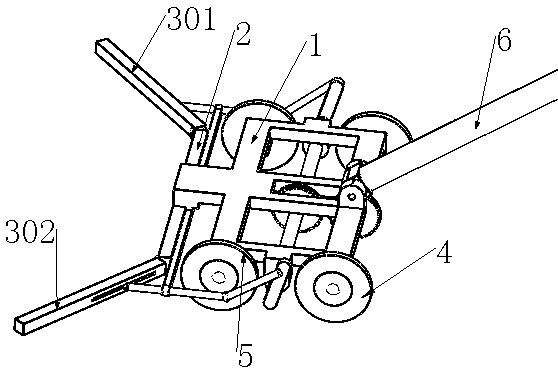

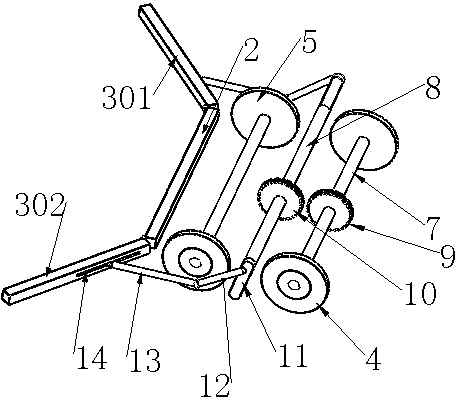

[0025] Below with reference to the accompanying drawings, through the description of this embodiment, the specific embodiments of the present invention, such as the shape, structure, mutual position and connection relationship between each part, the work and working principle of each part, etc., will be further described. instruction of.

[0026] Such as figure 1 , figure 2 The garbage cleaning device shown includes a body panel 1, the rear end of the body panel 1 is movably connected to the rotating shaft 7 through the bearing seat, the body panel 1 is also movably connected to the transmission shaft 8 through the bearing seat, and the front end of the body panel 1 is also moved through the bearing seat Connect the front roller shaft, the rotating shaft 7, the transmission shaft 8 and the front roller shaft are parallel to each other; the left and right ends of the rotating shaft 7 are fixedly connected to the rear wheel 4, and the middle position is fixedly connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com