Method of collecting garbage by swing garbage truck

A technology for collecting garbage and garbage trucks. It is applied to cleaning methods, manual sweeping machines, and drying to save seeds. It can solve the problems of easy slipping from the brooms on both sides, waste of resources, waste, etc., and achieve easy replacement of parts and components. Efficient cleaning of leaves, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below with reference to the accompanying drawings, through the description of this embodiment, the specific embodiments of the present invention, such as the shape, structure, mutual position and connection relationship between each part, the work and working principle of each part, etc., will be further described. instruction of:

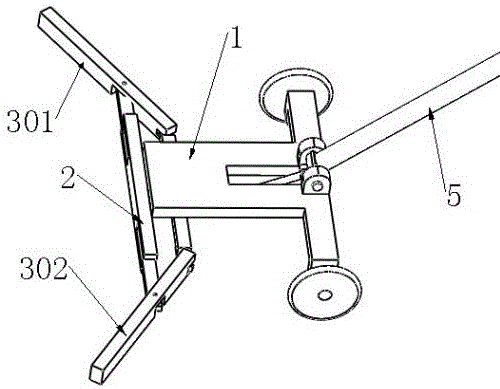

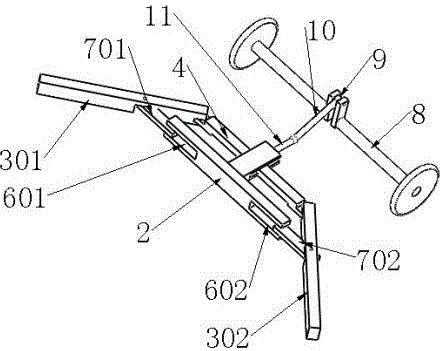

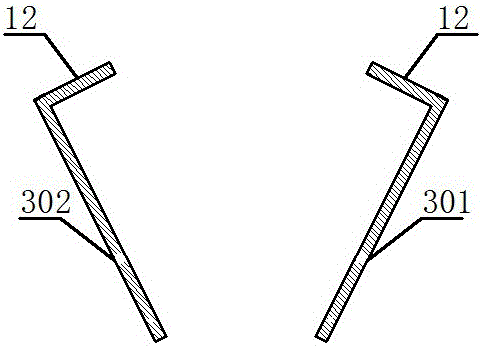

[0025] Such as figure 1 The shown tiger's mouth swallowing type garbage collection and cleaning device includes:

[0026] The body panel 1 is movably connected with the handle bar 5. The handle bar 5 can rotate freely at 180 degrees in the plane formed by the hand bar 5 and the center line of the body panel 1. The handle bar 5 It is a telescopic rod, which is convenient for the operator to clean up, and the length of the handle rod 5 can be adjusted to suit different operators.

[0027] The front end of the body panel 1 is fixedly connected to the support plate 2, and the bottom of the support plate 2 is detachably connected to a plug-in p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com