Automatic cocoon feeding machine set

A unit and automatic technology, applied in the direction of silk reeling, etc., can solve the problems of easily damaged cocoons and low degree of automation, and achieve the effects of saving labor, reducing violent collisions, and reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

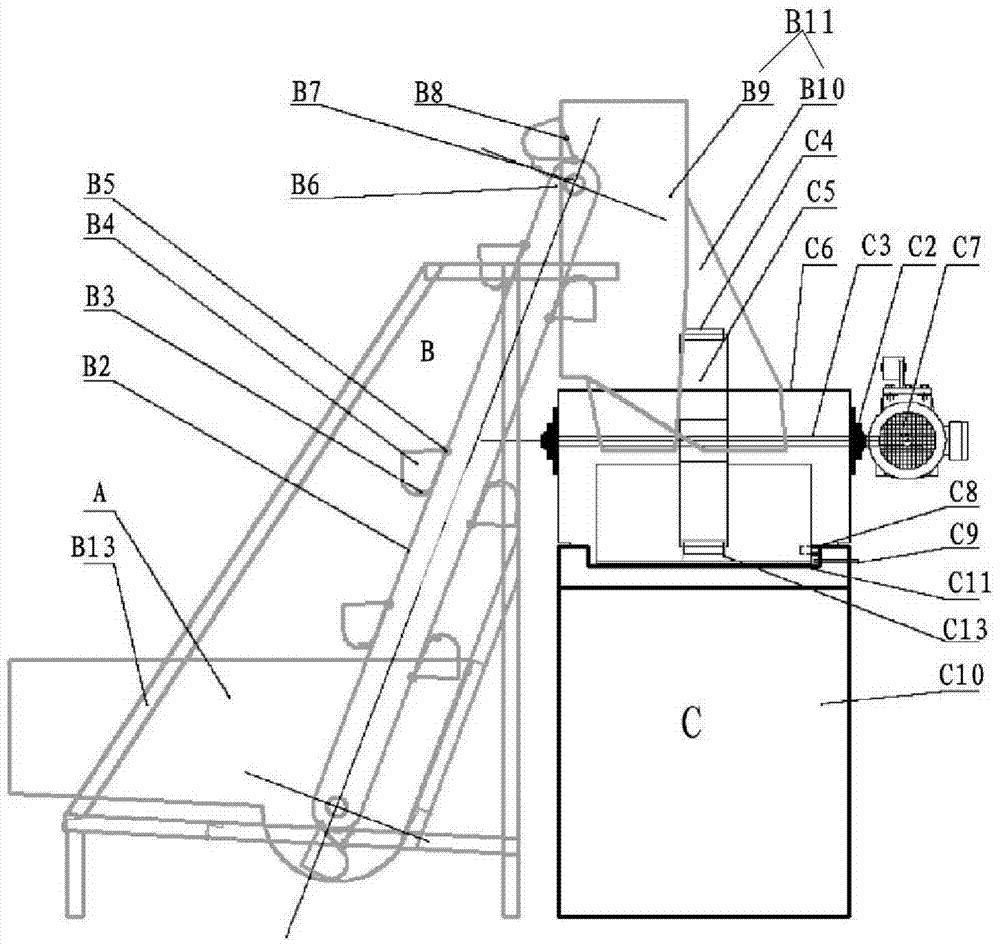

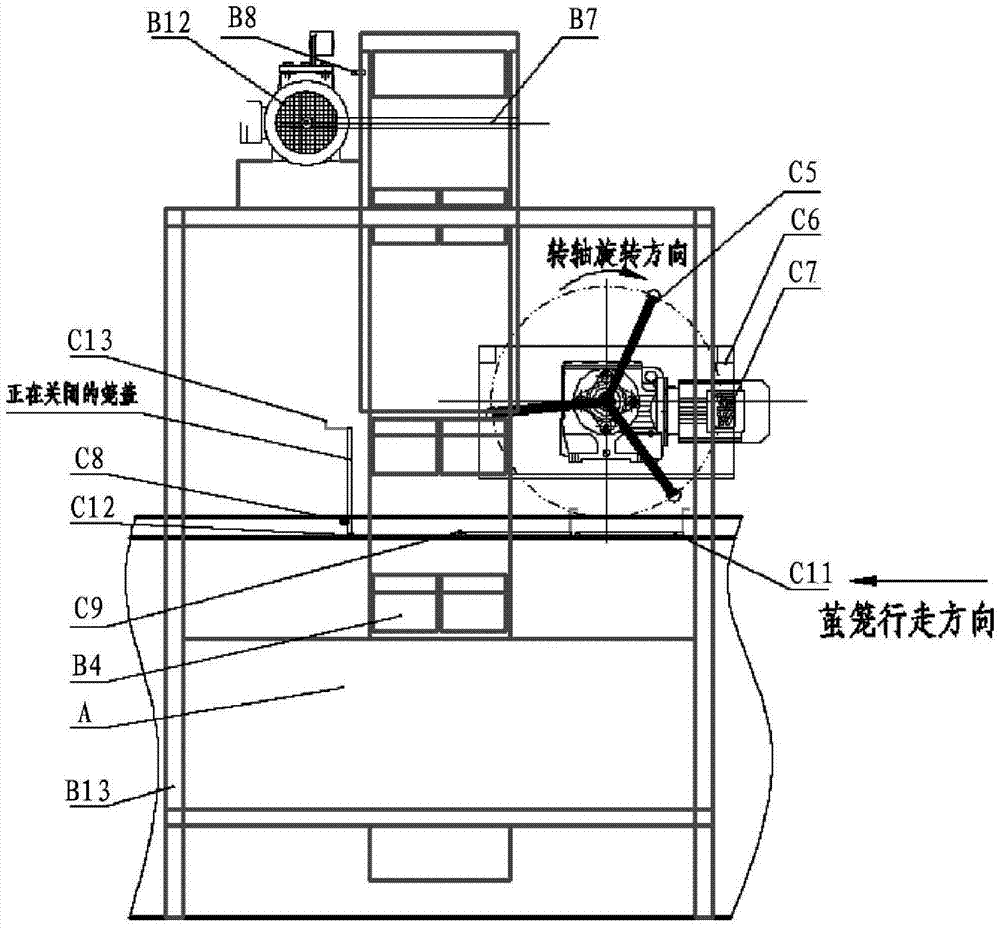

[0038] Such as Figure 1-4 As shown, the automatic cocoon adding unit includes a cocoon storage barrel A, a bucket lifting quantitative cocoon adding device B and a quick switch cocoon cooking cage cover device C.

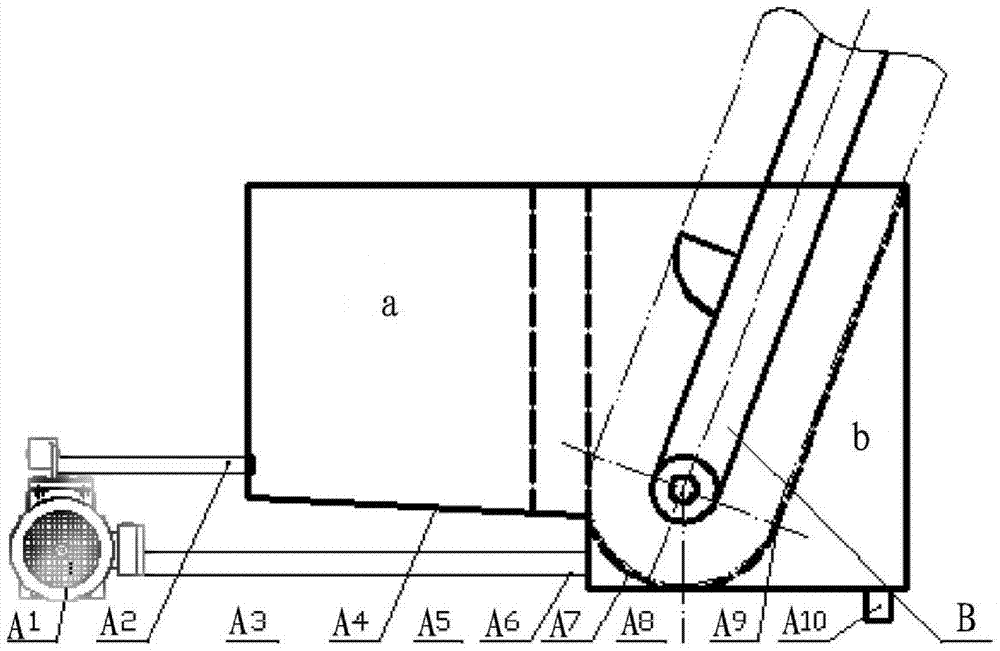

[0039] Cocoon storage barrel A includes a storage barrel. The storage barrel includes a barrel wall A3 and a barrel bottom A4. The storage barrel is divided into two parts: the front storage barrel a and the rear storage barrel b by a sealed partition A5. The bottom of the rear storage barrel b is larger than the front storage barrel. The bottom of b should be low, and the rear storage barrel b is provided with an arc bottom surface A7, and the rear inclined plate A9 connected with the arc bottom surface A7, the barrel bottom surface A4 and the arc bottom surface A7 have no clearance, and the barrel bottom surface A4 is provided with an inclination, an inclination The direction points to the arc bottom surface A7, and the positions on both sides of the arc bottom s...

Embodiment 2

[0052] The difference from Embodiment 1 is that in this embodiment, there are four flipping claws C5, and the rest of the working principles and calculation methods are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com