Efficient Gas Distributor

A gas distributor and high-efficiency technology, used in biochemical instruments, bioreactor/fermenter combinations, bioreactors/fermenters for specific purposes, etc. Poor and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

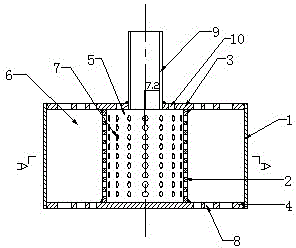

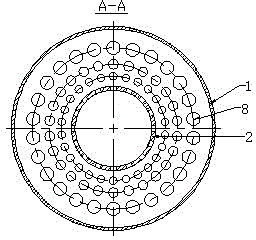

[0010] The high-efficiency gas distributor of the present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

[0011] As shown in the figure, the high-efficiency gas distributor of the present invention includes an outer cylinder 1 coaxially arranged and an inner cylinder 2 located in the outer cylinder 1, and the upper and lower end surfaces of the outer cylinder 1 and the inner cylinder 2 are covered by an upper cover The plate 3 and the lower cover plate 4 are sealed, the compressed air decompression chamber 5 is formed in the inner cylinder body 2, the dissolved oxygen exchange chamber 6 is formed between the outer wall of the inner cylinder body 2 and the inner wall of the outer cylinder body 1, and the upper cover plate 3 It is connected with an air intake pipe 9 that can make the compressed and purified air enter the compressed air decompression chamber 5, and the gas-water mixing and exchange holes 7 that can e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com