Microwave-assisted method for synthesis of oxidized corn starch from composite oxidant and composition

A technology of composite oxidant and corn starch, which is applied in the field of microwave-assisted composite oxidant synthesis of oxidized corn starch and the field of synthesis, can solve the problems of unsuitable mixing of reaction materials, high viscosity of reaction system, poor reaction effect, etc., and achieve transparency and freeze-thaw stability reduction, good viscoelasticity and plasticity, and less waste water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

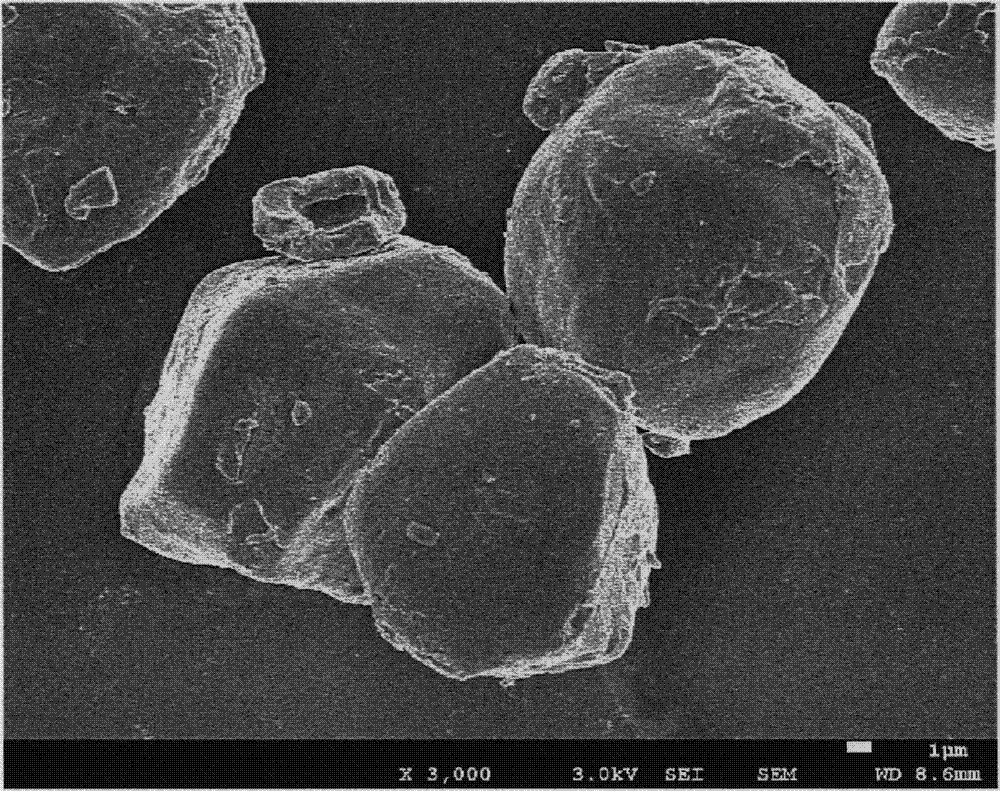

Image

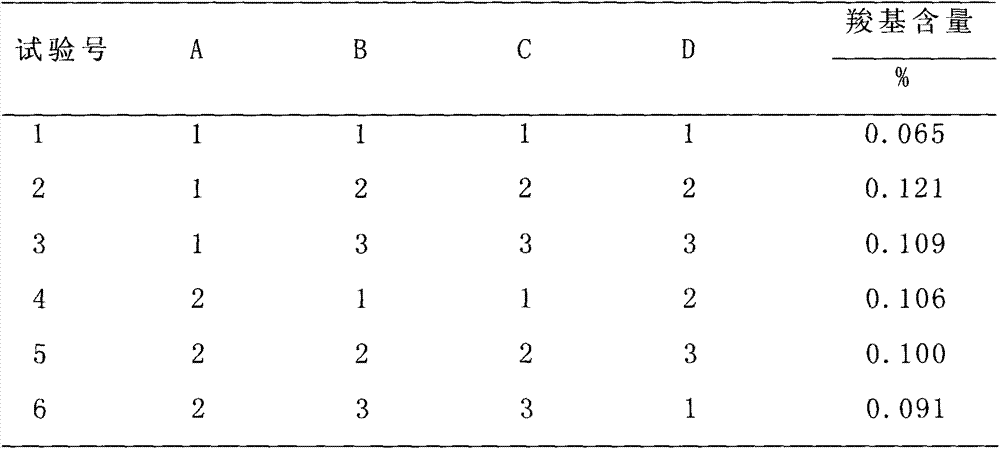

Examples

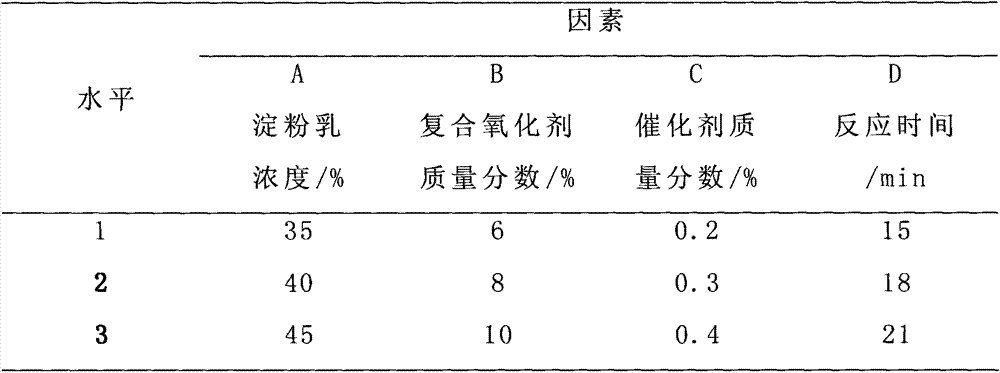

Embodiment 1

[0017] The method for the synthesis of oxidized cornstarch by microwave-assisted compound oxidant in this example comprises the following steps:

[0018] a, cornstarch is mixed with starch emulsion, and the concentration of starch emulsion is 35%;

[0019] b, adjust the pH value of the reaction system with hydrochloric acid, the pH value is 3.0~5.0;

[0020] c. Transfer the starch emulsion through steps a and b into a three-necked flask, and add 0.2% FeSO by mass fraction 4 Catalyst, and constant pressure slowly drop composite oxidant 6%;

[0021] d. React the above-mentioned starch emulsion under microwave radiation at a constant temperature for 15 minutes, and set the reaction temperature to 45°C-55°C; add 8mL-15mL of 10% sodium sulfite aqueous solution to terminate the reaction;

[0022] e. Wash the oxidized starch emulsion through step d with distilled water and ultrapure water successively, and suction filter after each washing. After washing several times, the filtrate...

Embodiment 2

[0024] The method for the synthesis of oxidized cornstarch by microwave-assisted compound oxidant in this example comprises the following steps:

[0025] a, cornstarch is mixed with starch emulsion, and the concentration of starch emulsion is 40%;

[0026] b. Adjust the pH value of the reaction system with hydrochloric acid, and the pH value is 3.0-5.0.

[0027] c. Transfer the starch emulsion through steps a and b into a three-necked flask, add FeSO 4 Catalyst 0.3%, and 8% composite oxidant was slowly added dropwise under constant pressure.

[0028] d. React the above-mentioned starch emulsion under microwave radiation at a constant temperature for 18 minutes, and set the reaction temperature to 45°C-55°C; add 8mL-15mL of 10% sodium sulfite aqueous solution to terminate the reaction;

[0029] e. Wash the oxidized starch emulsion through step d with distilled water and ultrapure water successively, and suction filter after each washing. After washing several times, the filtr...

Embodiment 3

[0031] The method for the synthesis of oxidized cornstarch by microwave-assisted compound oxidant in this example comprises the following steps:

[0032] a, cornstarch is mixed with starch emulsion, and the concentration of starch emulsion is 45%;

[0033] b, adjust the pH value of the reaction system with hydrochloric acid, the pH value is 3.0~5.0;

[0034] c. Transfer the starch emulsion through steps a and b into a three-necked flask, and add 0.4% FeSO by mass fraction 4 catalyst, and slowly add 10% of composite oxidant dropwise at constant pressure;

[0035] d. React the above-mentioned starch emulsion under microwave radiation at a constant temperature for 21 minutes, and set the reaction temperature to 45°C-55°C; add 8mL-15mL of 10% sodium sulfite aqueous solution to terminate the reaction;

[0036] e. Wash the oxidized starch emulsion in step d with distilled water and ultrapure water successively, and suction filter after each washing. After washing several times, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com