Luffing mechanism and full power speed regulation method of luffing mechanism

A technology of variable amplitude mechanism and speed regulation method, applied in cranes, load hanging components, transportation and packaging, etc., can solve the problems of power waste of variable frequency motors, and achieve the effect of solving power waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

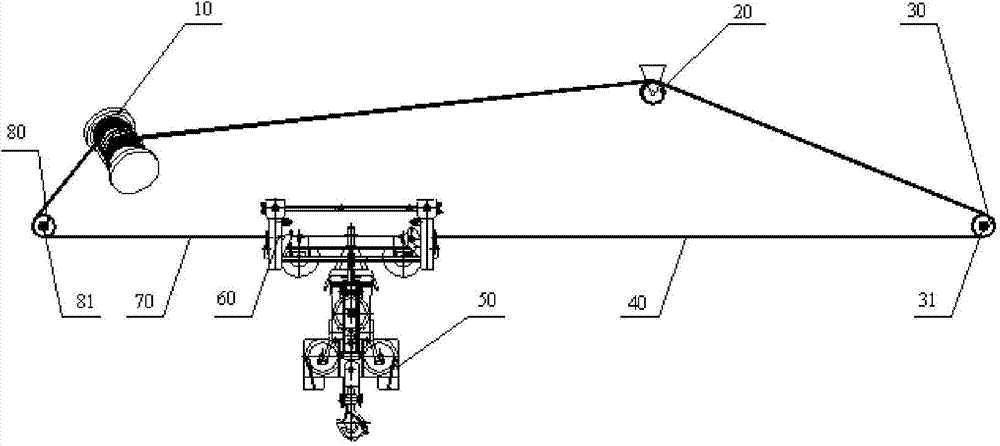

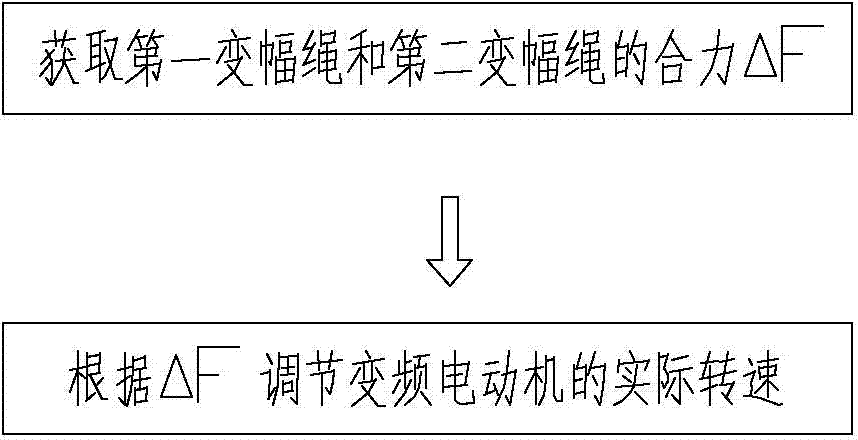

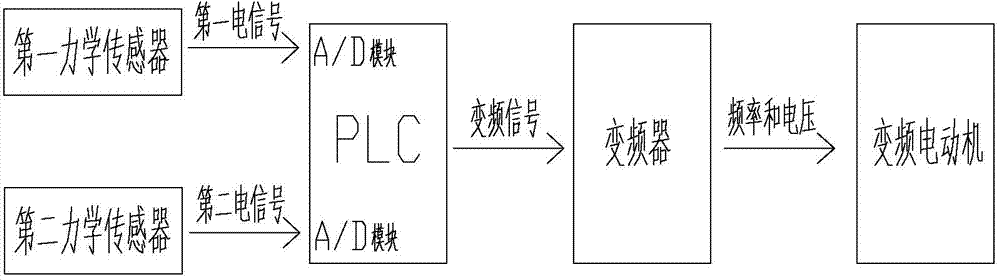

[0022] Such as figure 1 and figure 2 As shown, according to the first embodiment of the present invention, a luffing mechanism is provided, wherein the luffing reel 10 is driven by a variable frequency motor, and the luffing reel 10 is wound with a first luffing rope 40 and a second The luffing rope 70, the first luffing rope 40 goes out from the luffing drum 10, winds through the supporting wheel 20 and the arm tip pulley 30, and is fixed on the first side of the luffing trolley 60, the second luffing rope 70 After the rope is taken out from the luffing drum 10, it winds around the arm root pulley 80, and is fixed on the second side opposite to the first side of the luffing trolley 60, thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com