Processing tooling with respect to parting type winch friction plate

A friction disc and split technology, which is applied in the field of underground coal mine transportation equipment, can solve the problems of deformation, complicated maintenance, and increased safety hazards in coal mines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

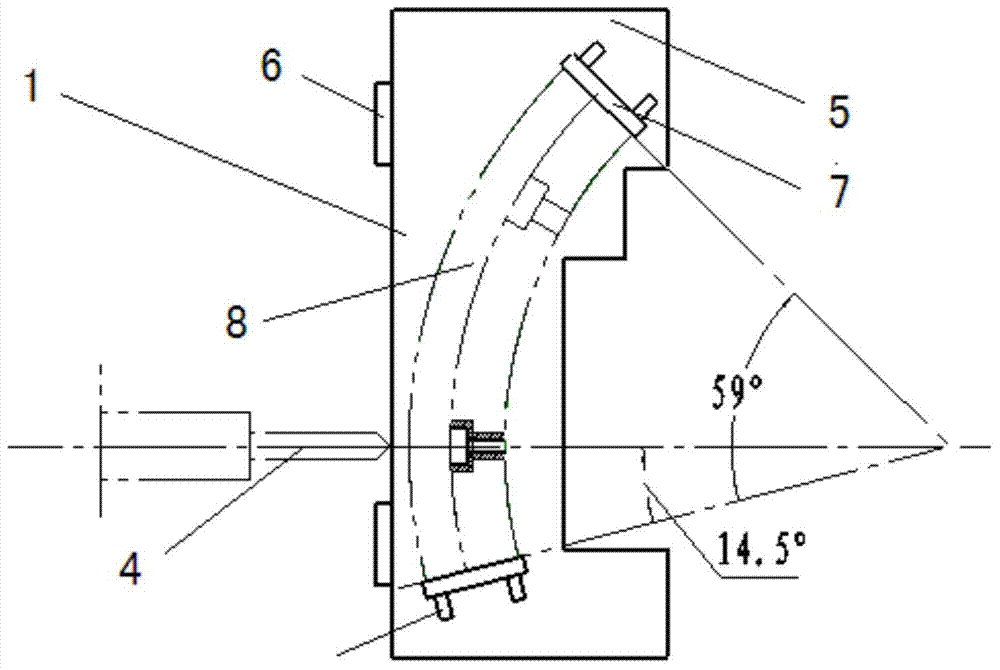

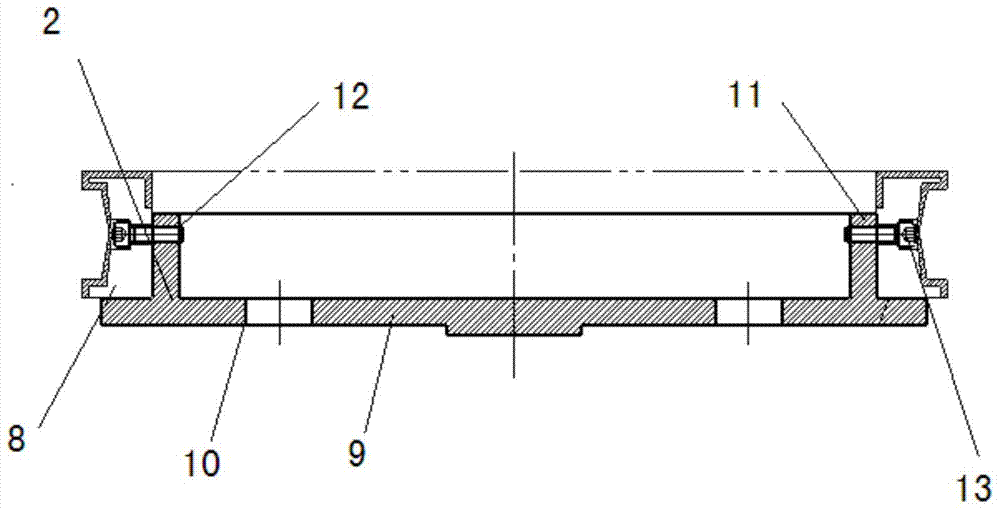

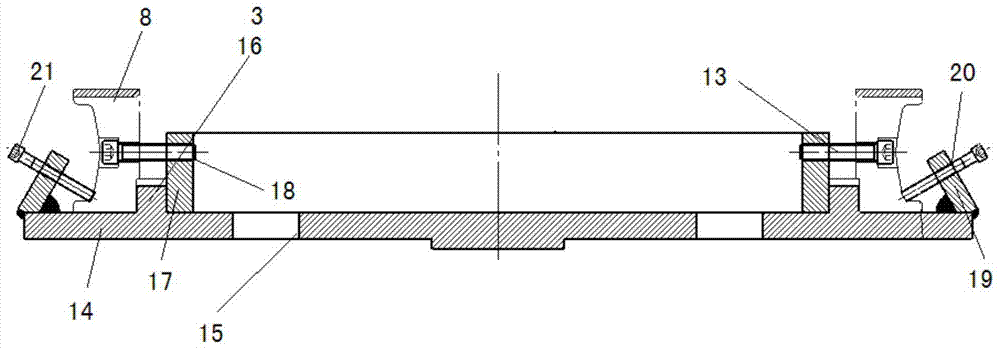

[0015] Such as figure 1 , 2 As shown in , 3, a set of processing tooling for the friction plate of the split winch includes a friction plate workpiece drilling device 1 and a friction plate workpiece surface processing device; the friction plate workpiece drilling device 1 includes a drill bit 4 and a base plate 5 , two front stoppers 6 symmetrically arranged on the front side of the bottom plate and left and right side baffles 7 arranged on the bottom plate, the size of the two side baffles 7 is adapted to the two ends of the friction plate workpiece 8 to be processed, and the left baffle 7 and the bottom plate 5 form an angle of 14.5 degrees in the vertical direction, and the inner surfaces of the baffles 7 on both sides form an angle of 59 degrees; the friction plate workpiece surface processing device includes a friction plate workpiece outer surface processing device 2 and a friction plate workpiece inner circle processing device 3. The friction plate workpiece outer sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com