Electrostatic atomization method for evenly distributing particles

A technology of electrostatic atomization and particle uniformity, applied in liquid spraying equipment, liquid supply devices, spray devices, etc., can solve the problems of low cost, short-circuit particle distribution, unevenness, etc., achieve low cost, speed up volatilization and evaporation, and high promotion Effects with Applied Value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

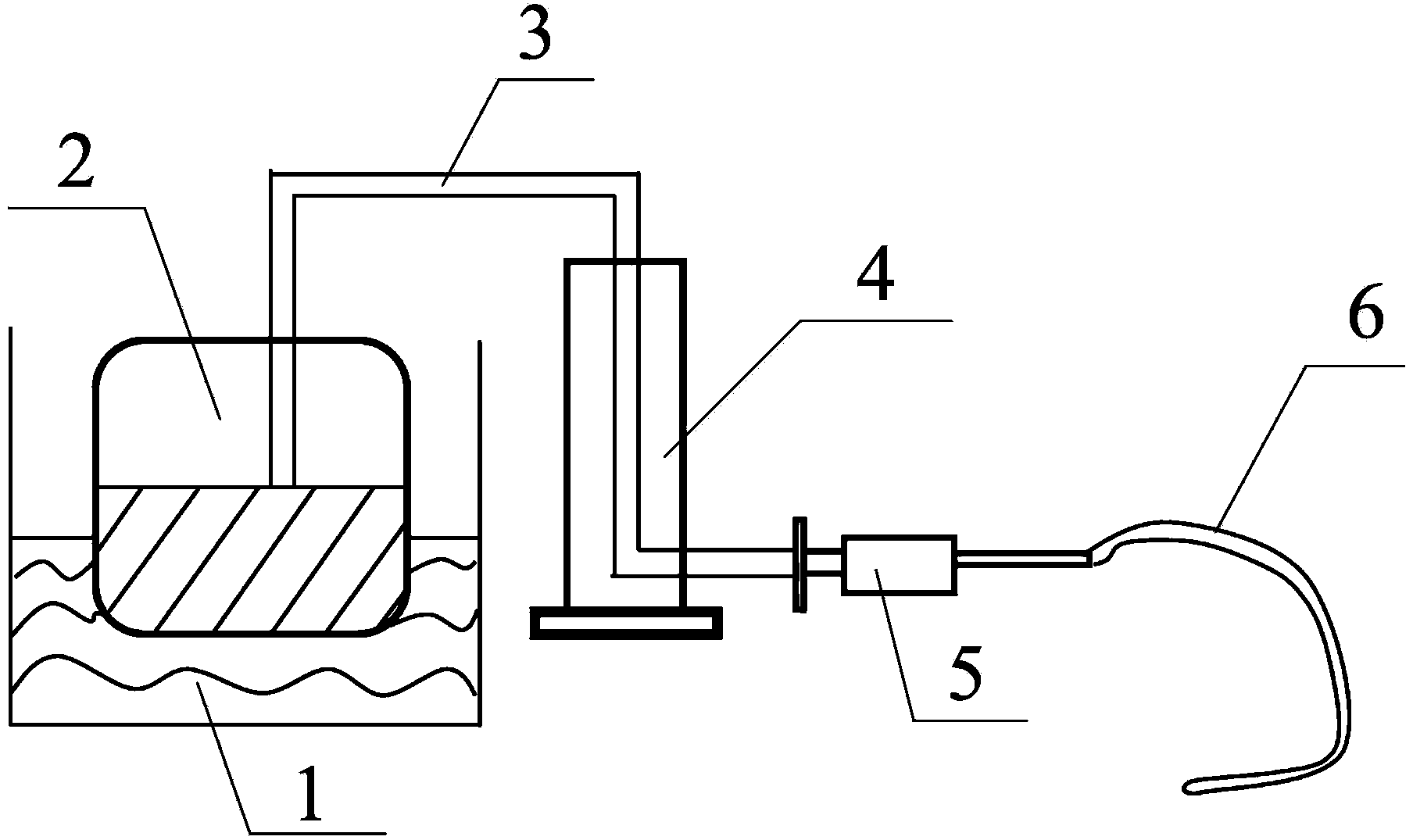

[0044] An electrostatic atomization method for uniform particle distribution, comprising the following steps:

[0045] 1. Select ethanol as the solvent, 0.03g of particles, 30g of solvent, the particles and the solvent are miscible to form a solution. Use an ultrasonic oscillator to perform ultrasonic vibration for 30 minutes to form a well-dispersed suspension.

[0046] 2. Set the flow rate of the micro-injection pump to 1ml / h, draw out the solution and push it to the needle.

[0047] 3. The outer diameter of the needle is 0.35mm, the inner diameter is 0.18mm, and the distance between poles is 20mm. The selected substrate is a silicon wafer with a diameter of 3.5 inches.

[0048] 4. Connect the positive pole of the voltage to the needle, and the substrate to ground. Adjust the voltage from 0 to 5.6kv slowly to form a stable atomization mode. Before forming a stable atomization mode, use the baffle to block the unstable droplets of different sizes formed in the previous mo...

Embodiment 2

[0052] An electrostatic atomization method for uniform particle distribution, comprising the following steps:

[0053] 1. Use isopropanol as the solvent, 0.05g of granules, 30g of solvent, and mix the granules and solvent to form a solution. Ultrasonic vibration for 30min forms a well-dispersed suspension.

[0054] 2. Set the flow rate of the micro-injection pump to 0.5ml / h, draw out the solution and push it to the needle.

[0055] 3. The outer diameter of the needle is 0.35mm, the inner diameter is 0.18mm, and the distance between poles is 20mm. The selected substrate is a silicon wafer with a diameter of 3.5 inches.

[0056] 4. Connect the positive pole of the voltage to the needle, and the substrate to ground. The regulation voltage slowly rises from 0 to 6.28kv to form a stable atomization mode. Before forming a stable atomization mode, use the baffle to block the unstable droplets of different sizes formed in the previous mode, and remove the baffle after the stable m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com