Cooking appliance control method

A control method and technology for cooking utensils, which are applied to dairy products, household utensils, kitchen utensils, etc., can solve the problems of residual beans on the pulp surface, excessively hard beans blocking the grinding head, and sticking beans at the bottom of the bean bucket, etc. The effect of preventing sticking to the bottom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0025] The invention provides a new control method for cooking utensils to solve the problems caused by the soymilk machine control method in the prior art, such as dry beans being too hard and blocking the grinding head, local sticky beans at the bottom of the dry and wet bean bucket, residual beans on the milk surface, and the amount of bean dregs. The problems encountered in the process of making soybean milk such as large and low solid content.

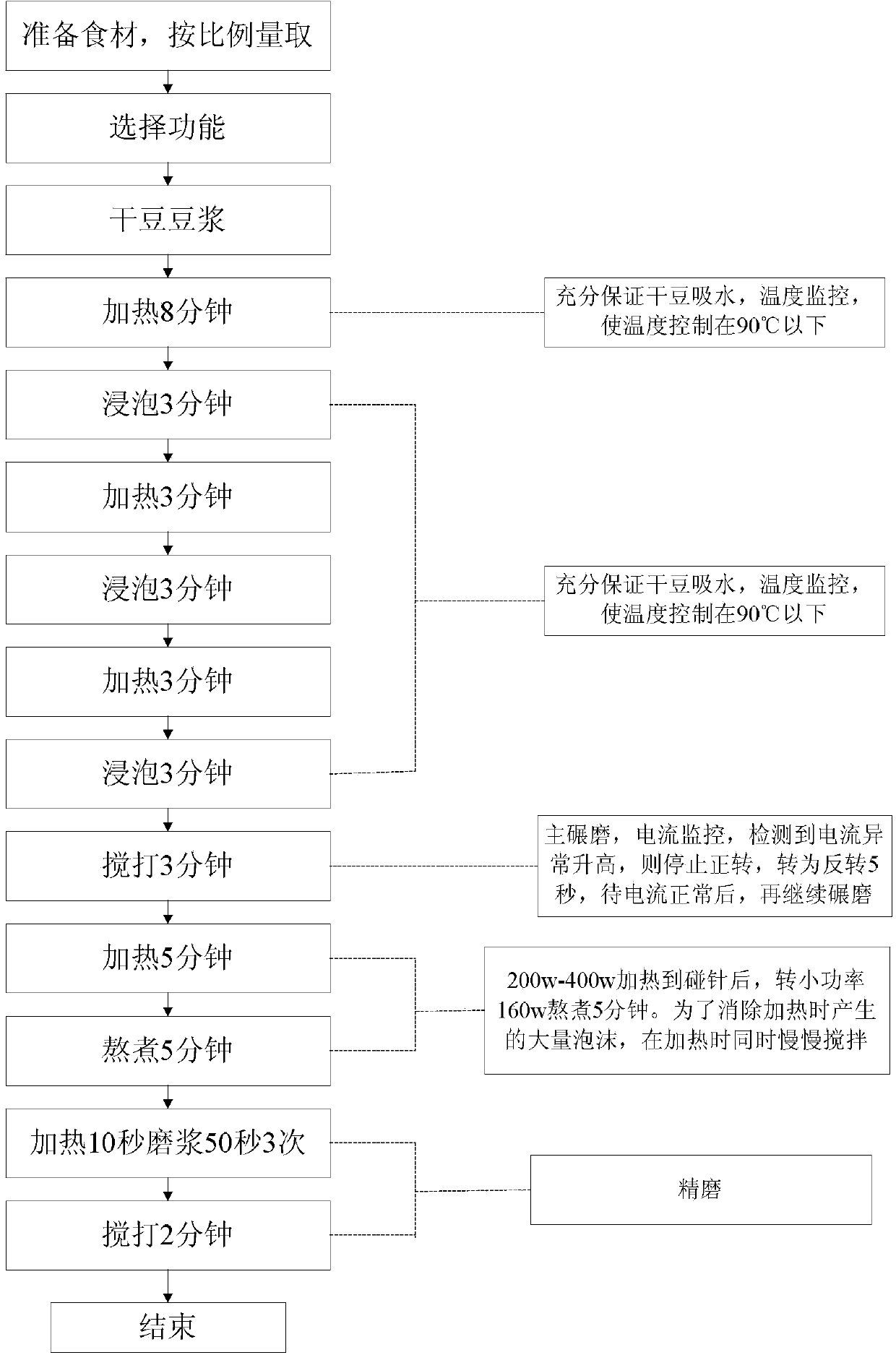

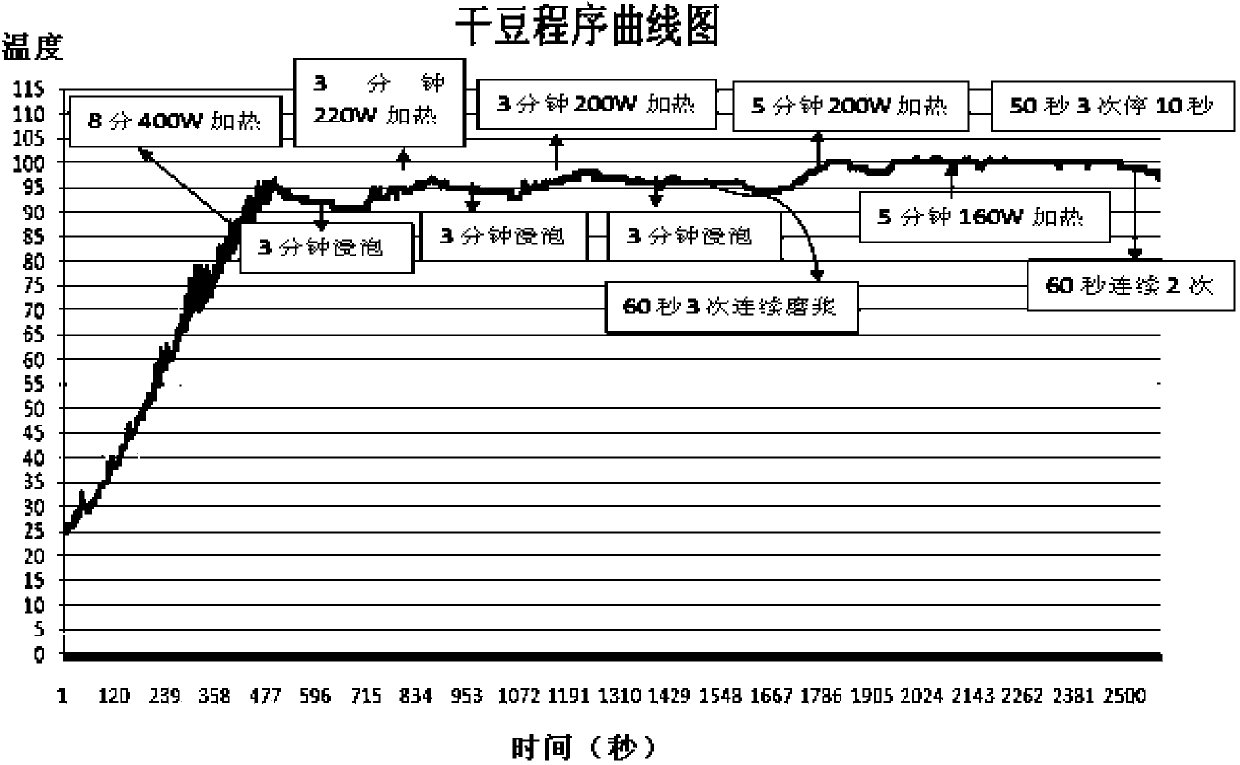

[0026] see figure 1 , image 3 As shown, the method of the first embodiment of the present invention: first prepare the ingredients and measure them according to the required ratio; select the dry bean soy milk in the function selection button; f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com