Method for regulating accumulator pressure

A tube pressure, regulating loop technology, applied in the direction of fuel injection control, engine control, machine/engine, etc., can solve problems such as harsh regulation deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

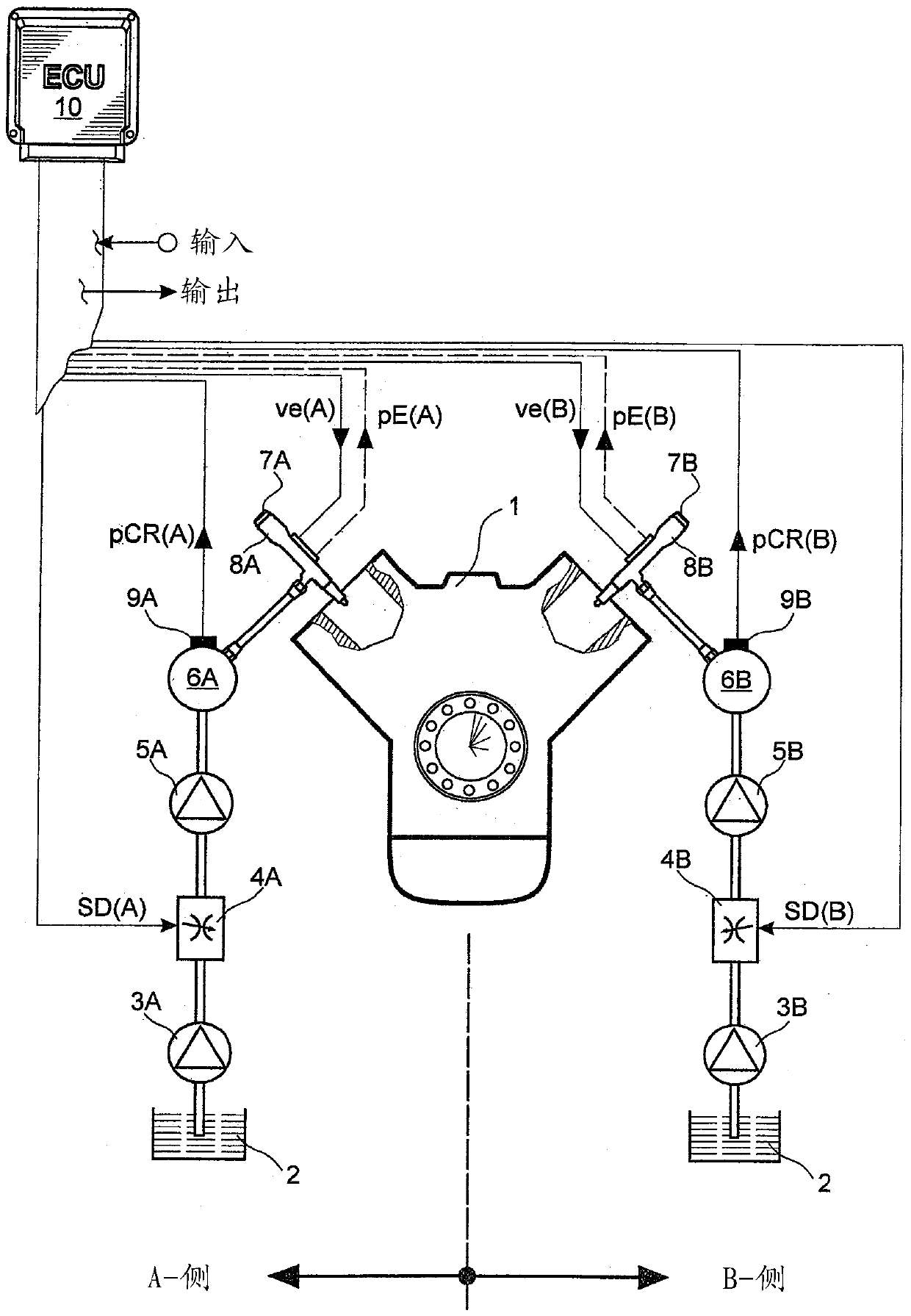

[0017] figure 1 A system diagram of an electronically controlled internal combustion engine 1 is shown with a common injection system on the A side and a common injection system on the B side. The common injection system on the A side comprises as mechanical part a low-pressure pump 3A for delivering fuel from the tank 2, a suction throttle 4A for influencing the volume flow, a high-pressure pump 5A, an accumulator 6A and a pump for injecting fuel. Injector 7A into the combustion chamber of internal combustion engine 1 . The common injection system on the B side consists of the same mechanical parts, which are identified by the same reference numerals appended with B.

[0018] Internal combustion engine 1 is controlled by electronic engine control unit 10 (ECU). exist figure 1 As input parameters of the electronic engine controller 10 are, for example, the A-side rail pressure pCR(A), the B-side rail pressure pCR(B) and the parameter EIN. The rail pressure pCR(A) on the A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com