Pressure monitoring method for liquid level of vehicle-mounted liquefied natural gas tank

An LNG tank and LNG technology, which are applied in the container discharge method, container filling method, gas/liquid distribution and storage, etc., can solve problems such as maintenance difficulties and vehicle-mounted LNG tank liquid level monitoring, etc., to facilitate fault maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the examples, but not as a limitation of the present invention.

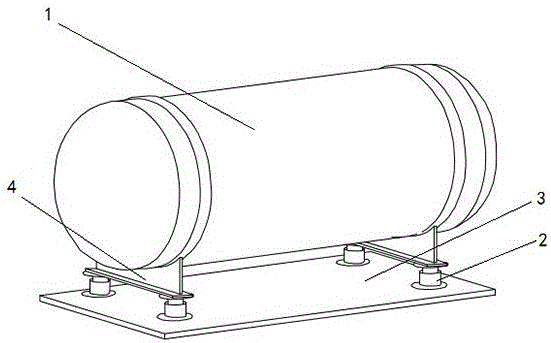

[0014] Please combine figure 1 First, a set of elastic support 2 is installed on the bottom plate 3 of the vehicle-mounted LNG tank 1, four elastic supports 2 are made according to the volume of the vehicle-mounted LNG tank 1, and the vehicle-mounted LNG tank 1 is installed on the elastic support 2. On the support 2. Install the four elastic supports 2 on the base of the support 4 of the liquefied natural gas tank 1, and adjust the position of the support 4 so that the center of gravity of the vehicle-mounted liquefied natural gas tank 1 coincides with the center of rigidity of the elastic support 2. The liquefied natural gas tank 1 and the elastic support 2 will form a four-degree-of-freedom rigid vibration system. A pressure sensor is installed on the elastic support, and the pressure sensor is used to collect data embedded in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com