Easy-to-mount computer case guide rail

A technology of guide rails and chassis, applied in the direction of rack/frame structure, etc., can solve the problems of troublesome disassembly, cumbersome manufacturing and installation procedures, and complicated structure of chassis guide rails, and achieve simple structure of chassis guide rails, convenient and fast installation, and good application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

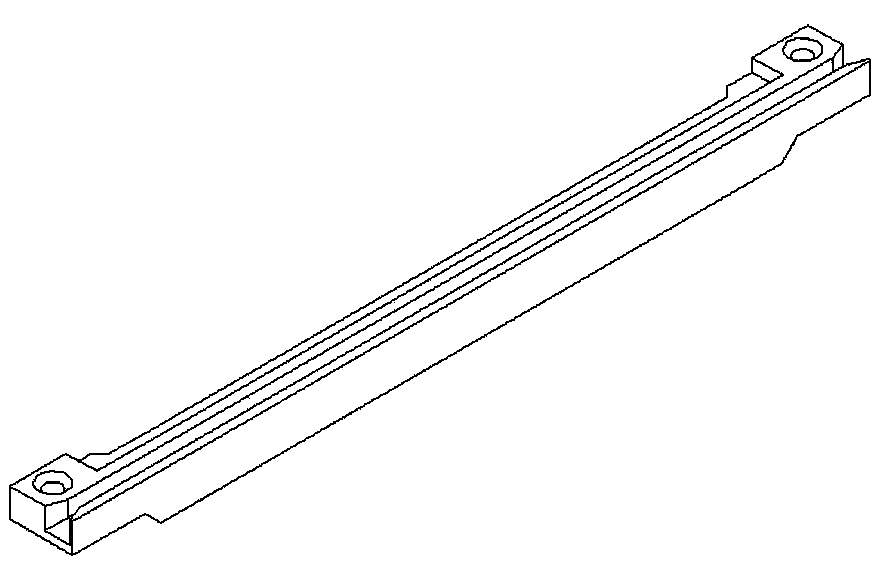

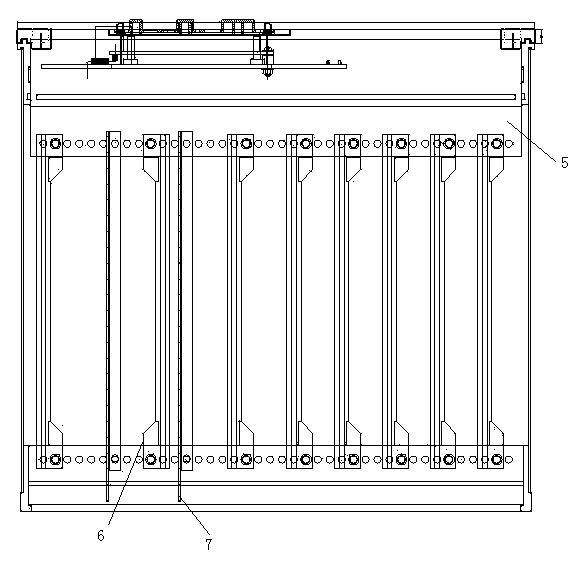

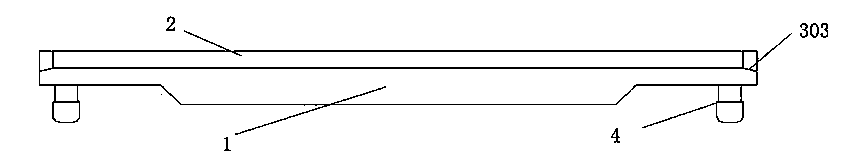

[0020] Such as Figure 3 to Figure 6 As shown, an easy-to-install chassis guide rail includes a guide rail body 1. A groove 2 is provided inside the guide rail body 1 along the length direction of the guide rail body 1. The groove 2 provides guidance for the insertion of subsequent printed boards, namely The printed board moves along the length direction of the guide rail body 1. In order to facilitate the subsequent printed board to enter the groove 2 smoothly, guide surfaces 3 are provided at both ends of the groove 2. In detail, the guide surface 3 includes The first guide surface 301 connected to the two sides of the groove 2, the second guide surface 302 and the third guide surface 303 connected to the bottom surface of the groove 2, the first guide surface 301, the second guide surface 302 and the third guide surface 303 are slopes formed by slanting. The first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com