Test method for intelligent substation station-control layer

A technology of intelligent substation and station control layer, which is applied in the detection of faulty computer hardware, functional inspection, electrical components, etc., can solve the problems of inability to meet the test of intelligent substation station control layer, lack of quantitative testing, etc., to simplify manual verification work Quantity, improve efficiency, and ensure the effect of correctness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention are described in detail below. The embodiments are implemented on the premise of the technical solution of the present invention, and detailed implementation manners and specific operation procedures are given.

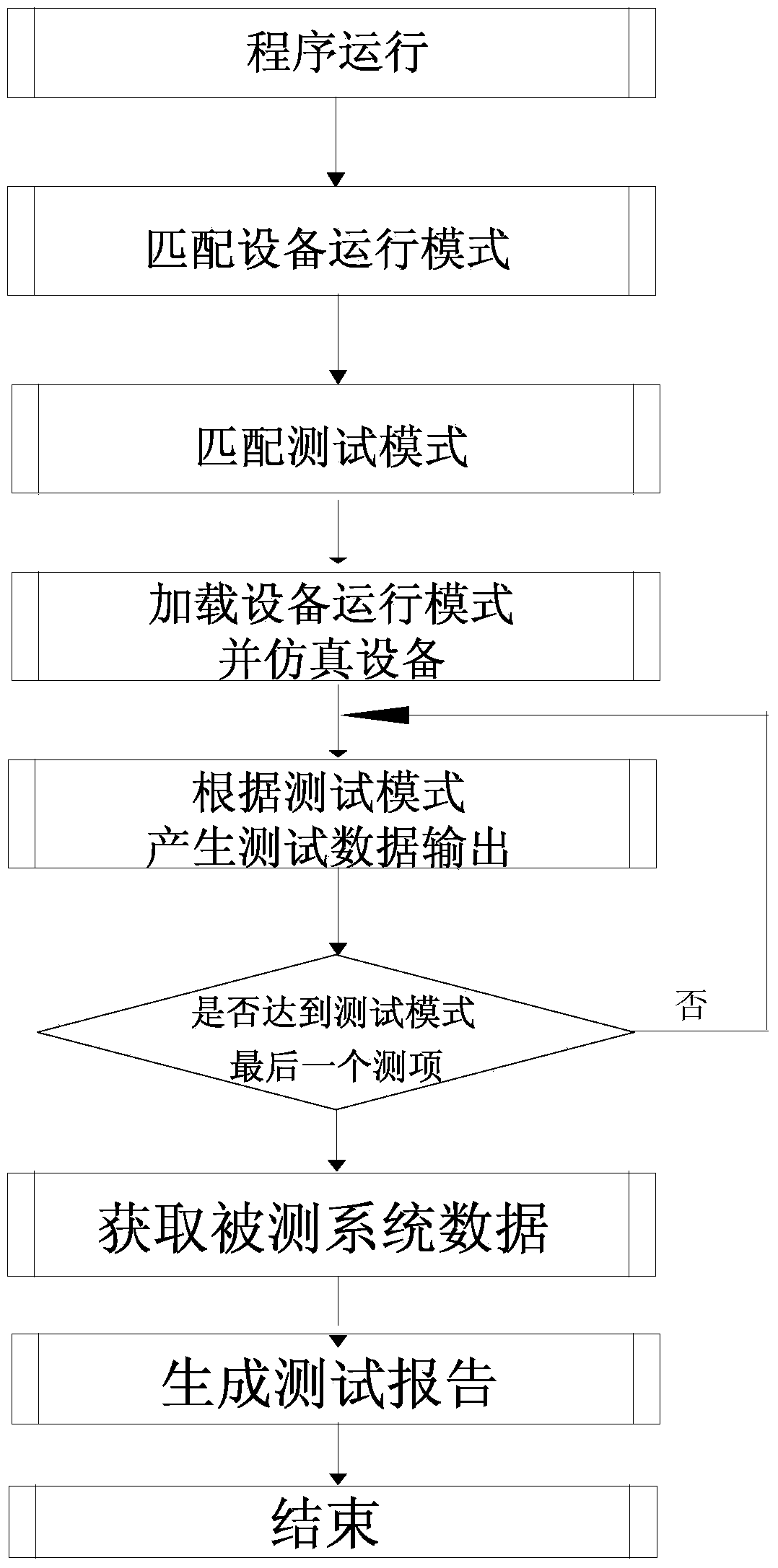

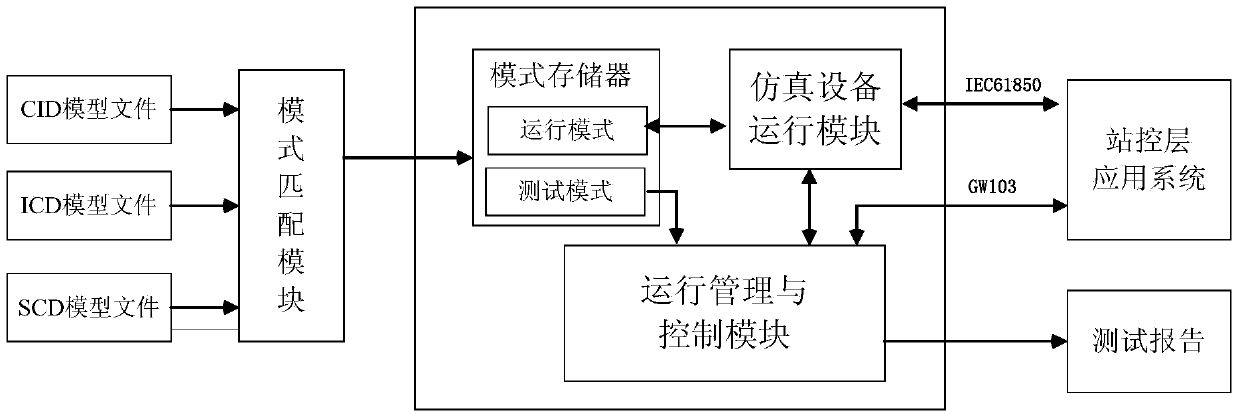

[0022] The invention establishes the IEC61850 intelligent equipment mode matching system, the IEC61850 simulation equipment operation system and the test management and control system. The whole test process is as follows figure 1 As shown, the test system modules are as figure 2 Shown. The entire test system module includes a pattern matching module, a pattern memory, a simulation device operation module, and an operation management and control module.

[0023] Among them, the pattern matching module data connection pattern library, the pattern library stores data files including CID model files, ICD model files, SCD model files, etc., and the pattern memory is used to store the operating modes and operating modes required ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com