Vehicle-mounted charger circuit

An on-board charger and circuit technology, used in hybrid) vehicles and electric (pure electric fields), can solve problems such as inability to achieve independent control, and achieve the effects of reducing cost and volume, improving utilization, and independent voltage control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

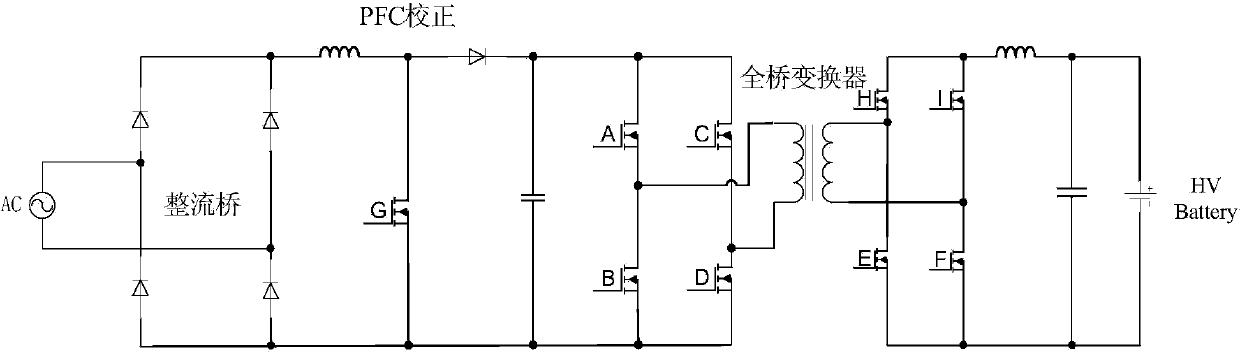

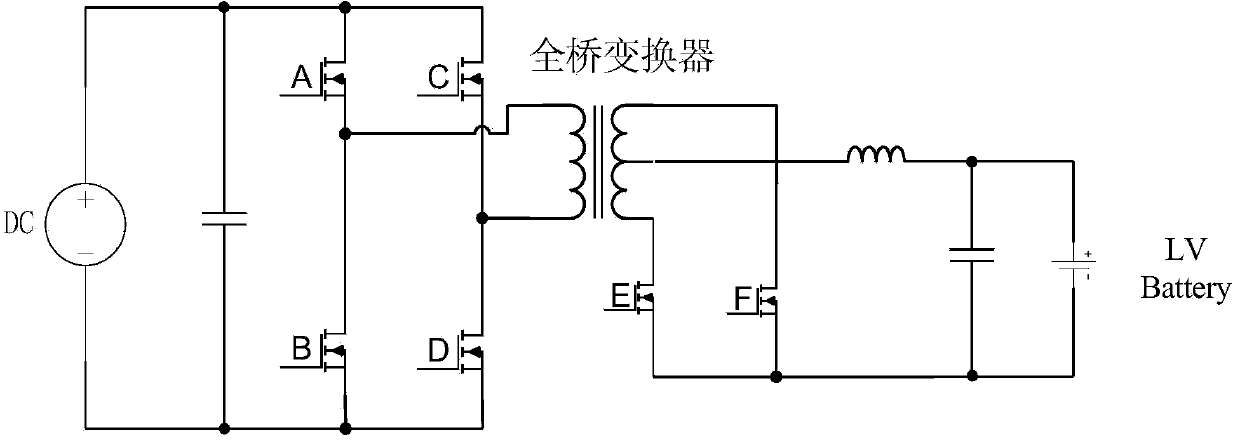

[0045] On-board charger circuits such as Figure 4 , Figure 5 As shown, including multiple output full bridge conversion circuit, PWM (Pulse Width Modulation) controller;

[0046] The multi-output full-bridge conversion circuit includes a first capacitor C1, a first switch M1, a second switch M2, a third switch M3, a fourth switch M4, a first inductor L1, a second capacitor C2, A transformer, a first rectifier circuit, a third capacitor C3, a second rectifier circuit, a fourth capacitor C4, and a second inductor L2;

[0047] The two ends of the first capacitor C1 are used as two input ends of a multi-output full-bridge conversion circuit for connecting to a DC voltage;

[0048] The first switching tube M1 and the second switching tube M2 are connected in series between two input terminals of the multi-output full-bridge conversion circuit;

[0049] The third switching tube M3 and the fourth switching tube M4 are connected in series between the two input terminals of the mu...

Embodiment 2

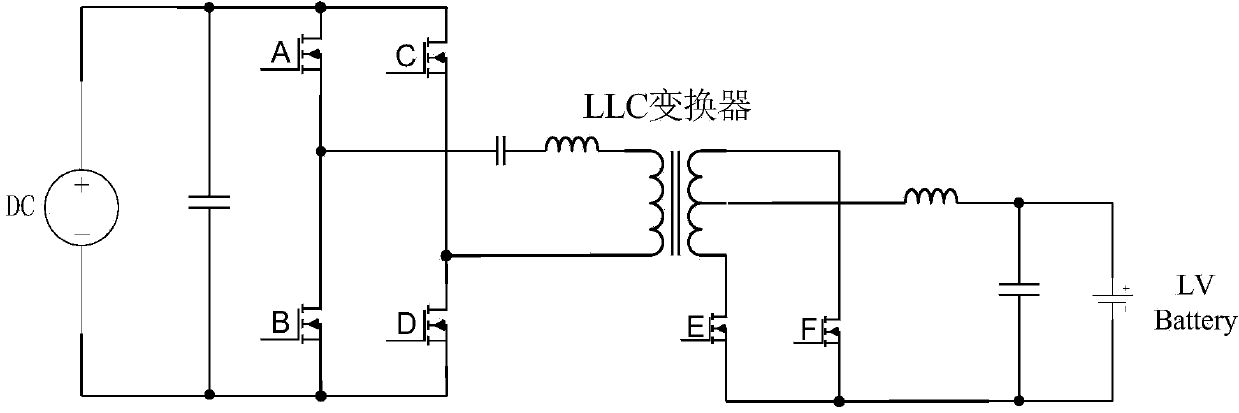

[0072] Such as Figure 6 The car charger circuit shown is the same as that of Embodiment 1 Figure 5 The difference between the shown circuits is that the multi-output full-bridge conversion circuit also includes a fifth capacitor C5;

[0073] The fifth capacitor C5 is connected between the two ends of the primary winding of the transformer, and the frequency of the PWM control signal is greater than

[0074] L1 is the first inductor, C2 is the second capacitor, and C5 is the fifth capacitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com