Phase shifting unit and MEMS (micro-electromechanical system) terahertz phase shifter composed of same

A phase shifter and terahertz technology, which is applied in the field of MEMS terahertz phase shifters, can solve problems such as the inability to meet the capacitance ratio and capacitance value in the terahertz frequency band, limit the design of MEMS beams, and the device size is too small to improve linearity And the effect of working bandwidth, suppressing high-order modes, and low insertion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

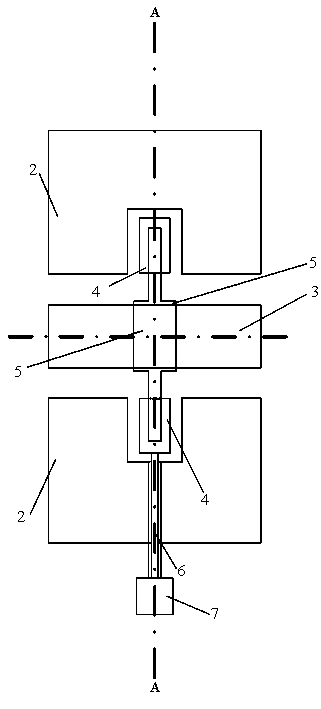

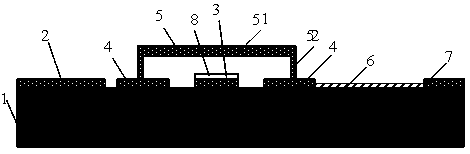

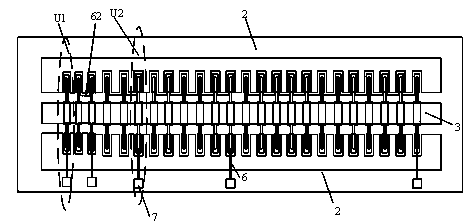

[0033] Such as figure 1 As shown, this embodiment provides a phase shifting unit, which mainly includes: a substrate 1, a CPW signal line 4 with an open terminal, a CPW signal line ground line 2, a CPW signal line 3, and a MEMS movable beam 5. Wherein, the substrate 1 has an insulating function, and adopts a thinned substrate with a low dielectric constant, the thickness of which is 100-300um, and the material is quartz, glass or a silicon substrate compatible with CMOS.

[0034] The material of the ground wire of the CPW signal line is a metal layer of Cr and Au / Cr, and the number is two, which are arranged on opposite sides of the substrate; at the same time, grooves are opened at the opposite ends of the two CPW signal line ground wires 2; correspondingly, There are two CPW signal wires with open terminals, and they are inserted into the ground wire of the CPW signal wire through the groove.

[0035] The CPW signal line is arranged on the substrate and located under the ME...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com