Bulb for detection

A light bulb and filament technology, which is applied in the field of standard light bulbs for luminous intensity detection, can solve problems such as difficulty in obtaining stable light intensity values, blackening of the bulb surface, and affecting light quality, and achieve good coplanarity, small area, and large luminous area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

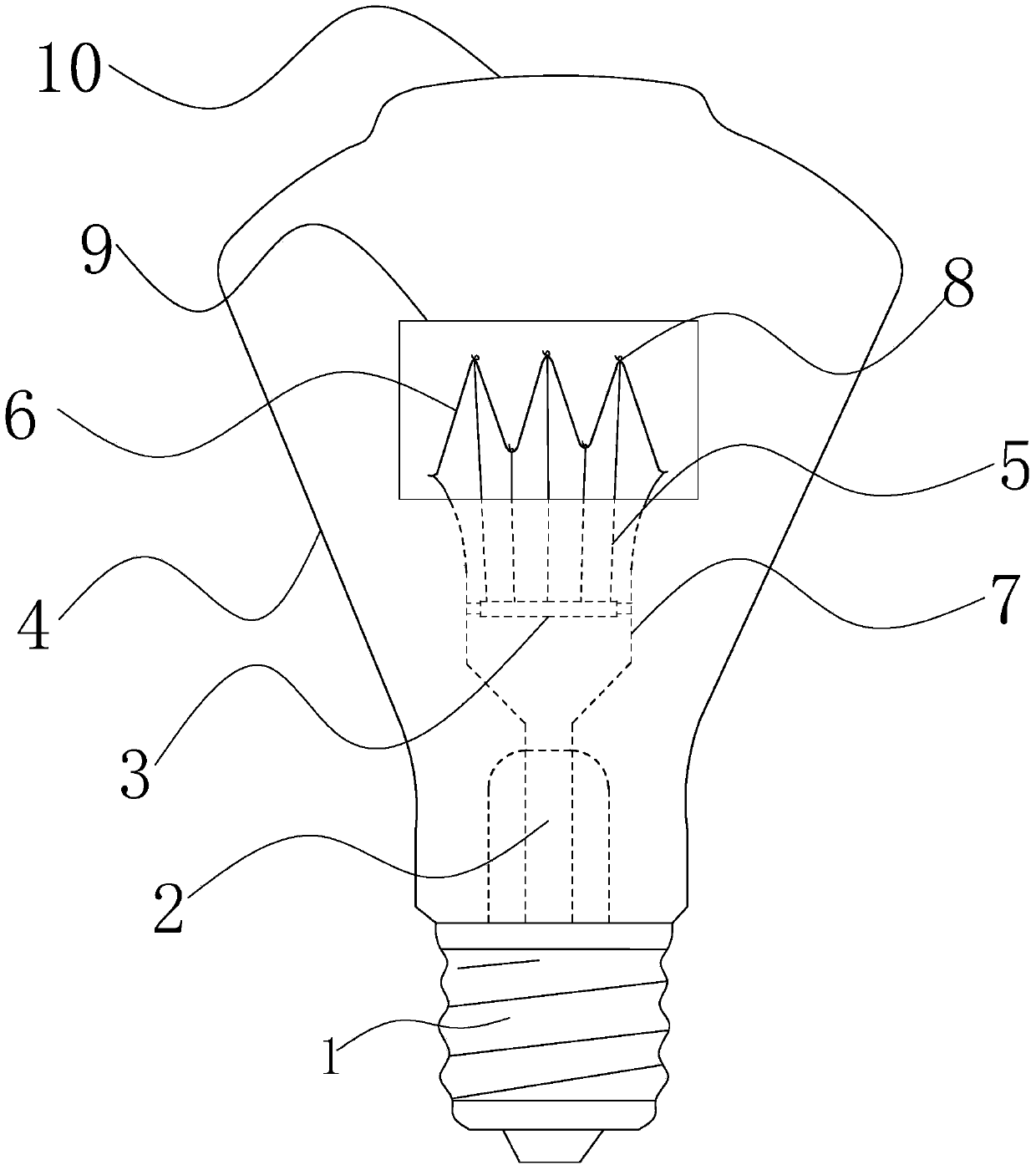

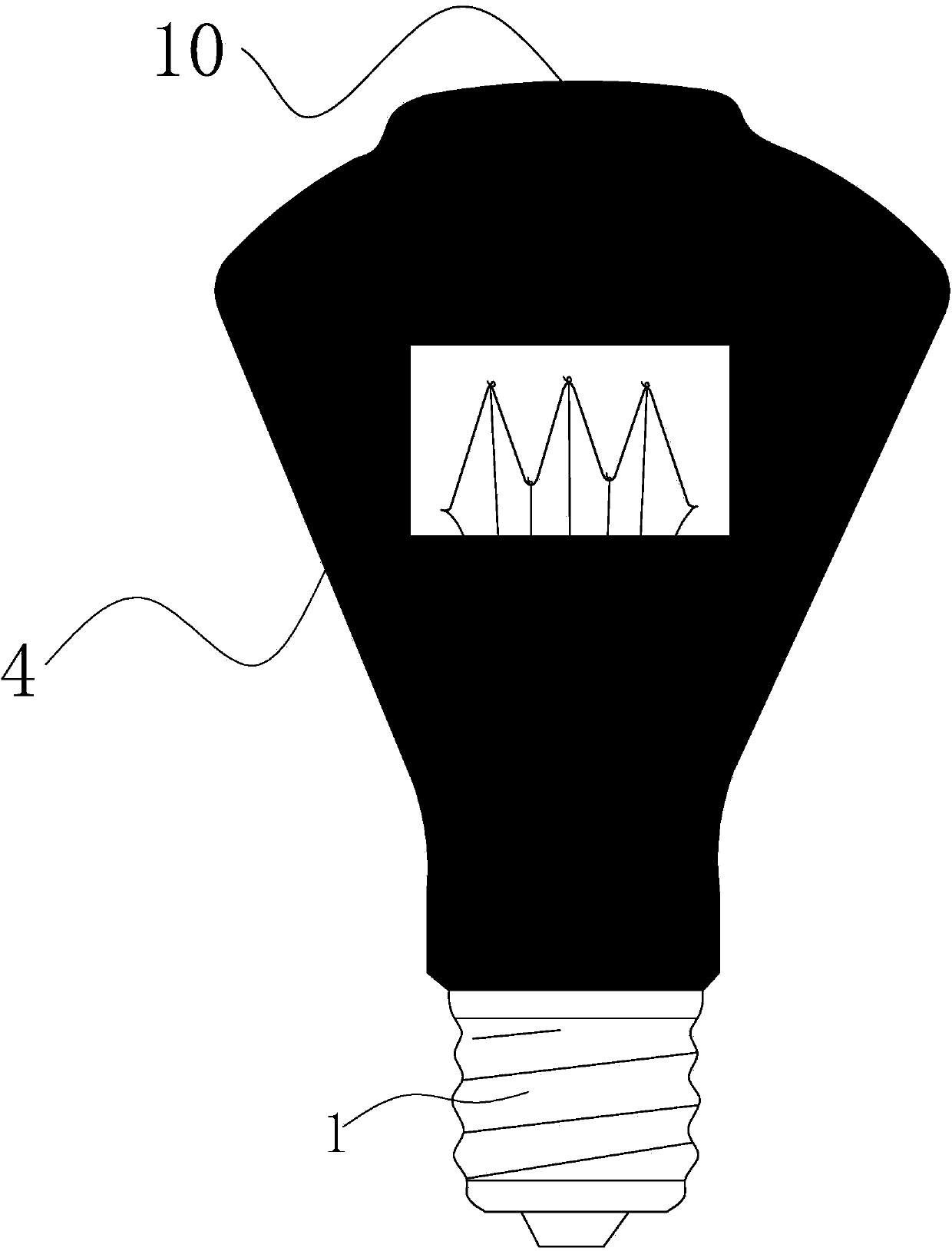

[0012] Such as figure 1 , figure 2 The shown bulb for detection includes a lamp base 1, a glass bulb 4, a stem 2 and a filament 6 are arranged inside the bulb 4, two guide wires 7 are drawn out of the stem 2, and the two ends of the filament 6 are They are respectively connected with two guide wires 7. When the lamp holder 1 is on the bottom and the glass bulb 4 is on the top, the lamp as a whole is in the shape of an inverted cone or a rounded platform, and the upper end surface of the glass bulb 4 is an arc surface; and the arc surface The center is provided with an arched protrusion 10, which accounts for 1 / 2-2 / 3 of the entire arc surface, and the height of the arched protrusion 10 is 3-8cm, and the inner wall of the glass bulb 4 is painted black , a rectangular or square light-transmitting window 9 is only provided on the glass bulb 4 dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com