Direct-injection gas burner without flame

A flameless combustion and direct injection technology, which is applied to gas fuel burners, burners, combustion types, etc., can solve the problems of complex structure and high manufacturing cost, and achieve the effects of easy implementation, low manufacturing cost and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

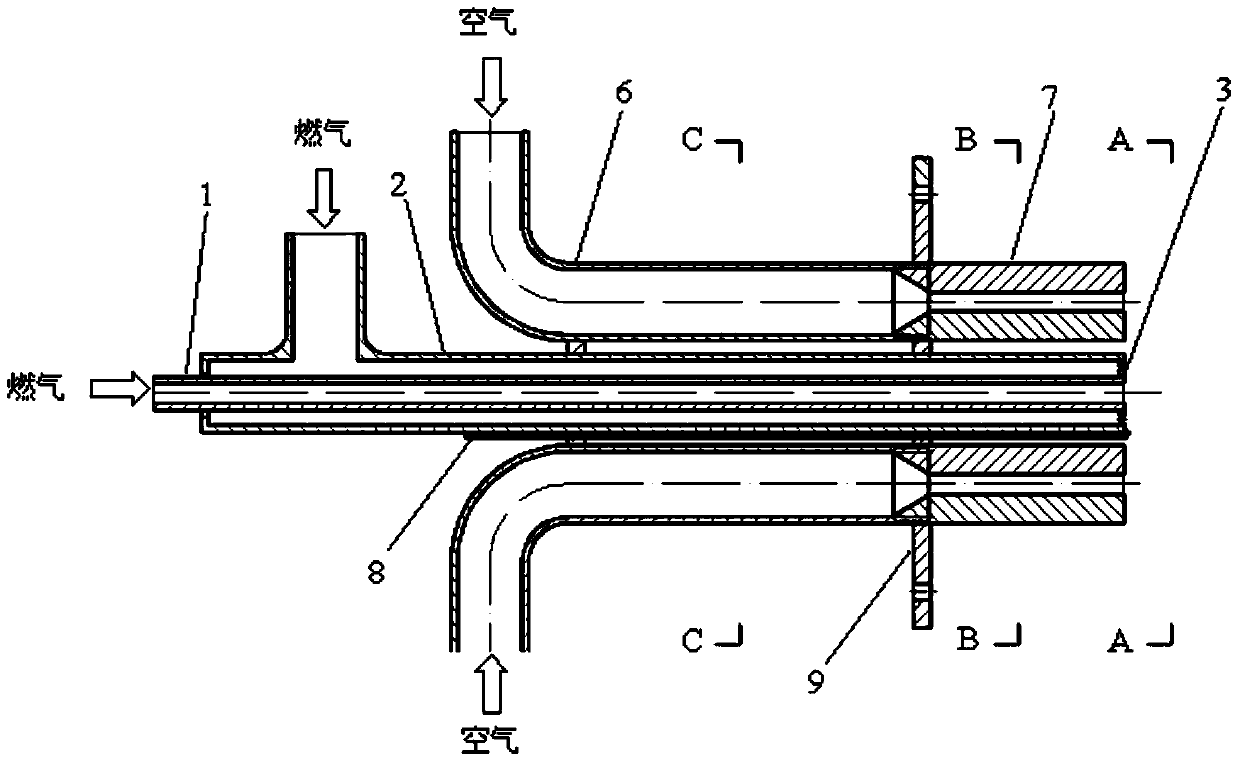

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

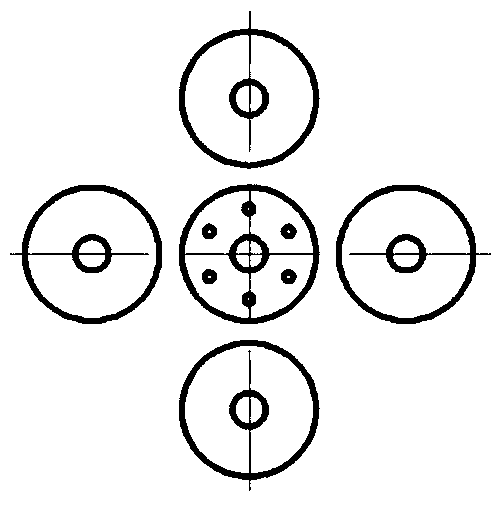

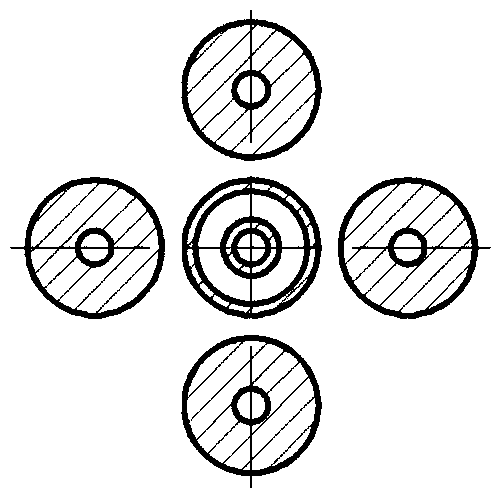

[0022] like Figure 1~5 As shown, the present invention includes a horizontally arranged inner gas pipe 1 and an outer gas pipe 2 coaxially sleeved outside the inner gas pipe 1 , and there is an annulus between the inner gas pipe 1 and the outer gas pipe 2 . A circular gas nozzle 3 is installed at the outlet end of the inner gas pipe 1 and the outer gas pipe 2, and a central fire hole 4 communicating with the inner gas pipe 1 is arranged in the center of the gas nozzle 3, and a plurality of rings are arranged around the central fire hole. Connected peripheral fire holes 5. Four air pipes 6 are symmetrically arranged around the outer gas pipe 2 (this is only an example, not limited to this), and an air nozzle 7 is respectively installed at the outlet end of each air pipe 6, and each air nozzle 7 is connected to the gas The outer end faces of the nozz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com