Simulation Control System of Engine Fuel Injector

A technology of analog control and fuel injectors, which is applied in the direction of engine components, engine testing, machine/engine, etc., can solve the problem that the control circuit is only applicable, and achieve the effects of improving accuracy, reliable communication, and stable system performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

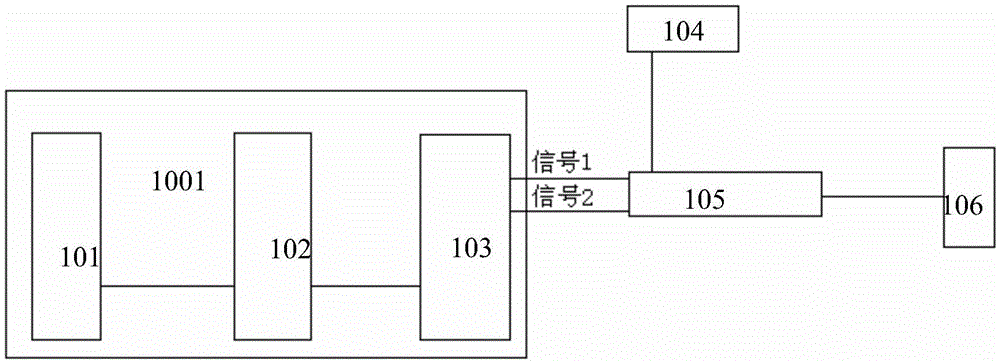

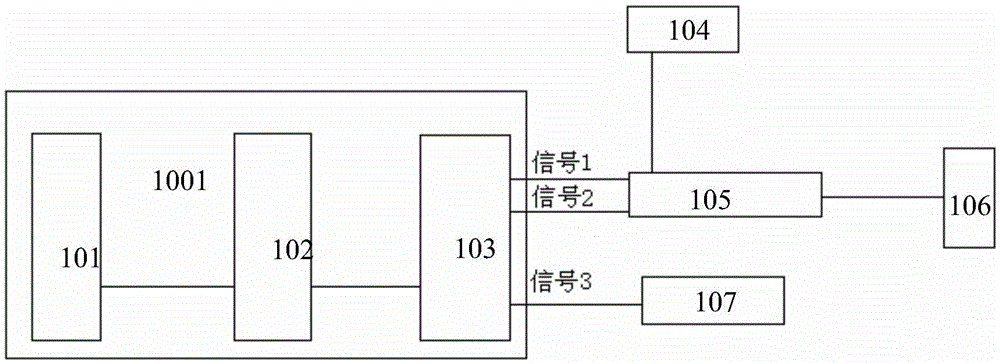

[0049] like image 3 As shown, the engine fuel injector analog control system includes: a PC 101, a level conversion circuit 102 connected in series with the PC, which converts the level signal of the RS232 serial communication of the PC into a TTL level signal of the single-chip microcomputer; The ECU electronic control unit 103 connected in series with the level shifting chip; the fuel injector drive circuit 105 connected in series with the ECU electronic control unit, the boost circuit 104 and the fuel injector 106 respectively connected to the drive circuit; the series connection with the ECU electronic control unit Connected high-speed camera 107.

[0050] like Image 6 As shown, the gasoline engine fuel injector drive circuit 105 includes: IR2101 type drive chip, the pin 1 of the IR2101 type drive chip is connected to the +12V power supply, and the pin 2 is connected to the pin 4 of the first optocoupler. Pin 4 is grounded;

[0051] a first optocoupler whose pin 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com