Prestressed concrete beam plate with upper portion provided with flexural steel bars and frame structure system

A technology for concrete beams and frame structures, which can be used in building structures, buildings, etc., can solve the problems of high-altitude support formwork, high cost, unreliability, and high cost of quasi-frame beams.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

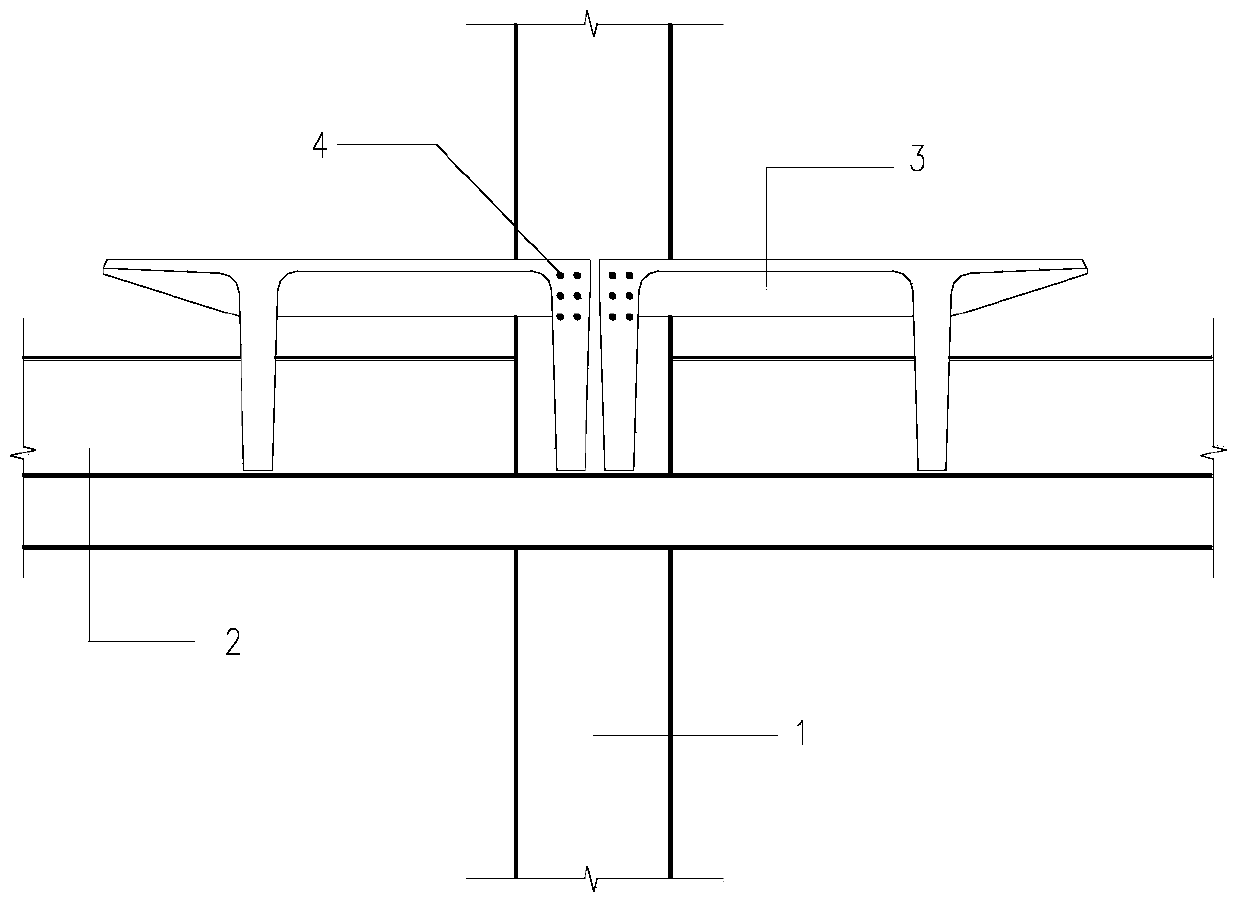

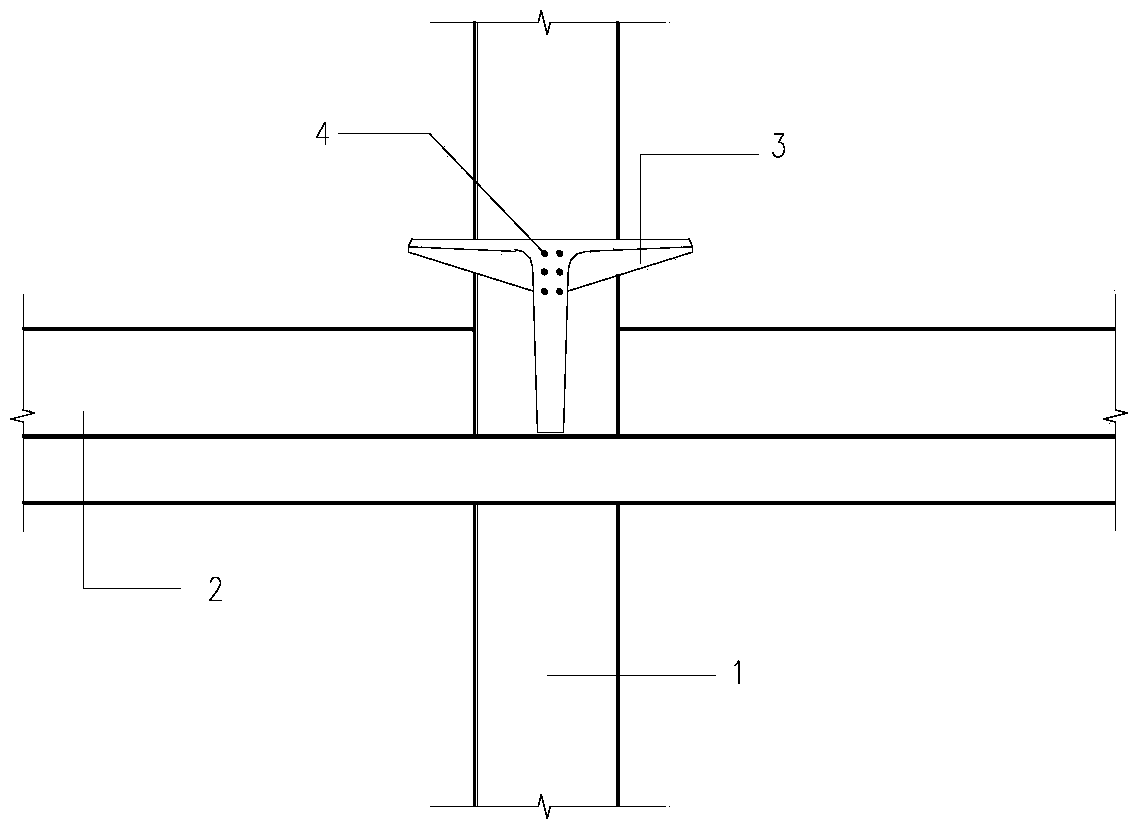

[0013] As shown in Figure 1: 1 is the column; 2 is the corbel beam on the column; 3 is the large-span prestressed double T plate with one flange removed; 4 is the bending steel bar on the upper part of the double T plate.

[0014] The frame column 1 and the corbel 2 on the column are built by the conventional method, and two double T-plates 3 and double ribs with corresponding flanges removed are combined and arranged on the corbels of the frame column 1 at both ends, and the bending reinforcement 4 on the plate is connected with The column reinforcement is connected, the lower embedded part is connected with the upper embedded part of the corbel beam, or the double T-plate end mustache reinforcement is connected with the column reinforcement, and a second pouring layer is made on the top to form a frame structure.

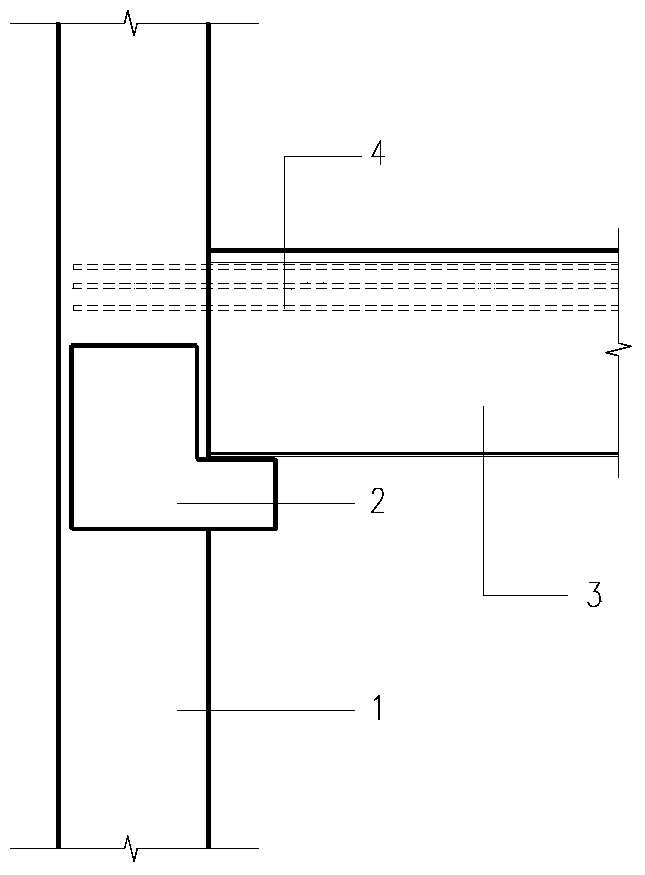

[0015] As shown in Figure 2, 1 is the column; 2 is the corbel beam on the column; 3 is the large-span prestressed single T plate; 4 is the bending steel bar on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com