High-conductivity carbon nanotube/rubber nanocomposite and preparation method thereof

A carbon nanotube and rubber nanotechnology, which is applied in the field of highly conductive carbon nanotube/rubber nanocomposite materials, can solve the problems of limited reinforcement of composite materials, poor aspect ratio of carbon tubes, and expected improvement in rubber properties. Achieve the effect of maintaining integrity and high aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

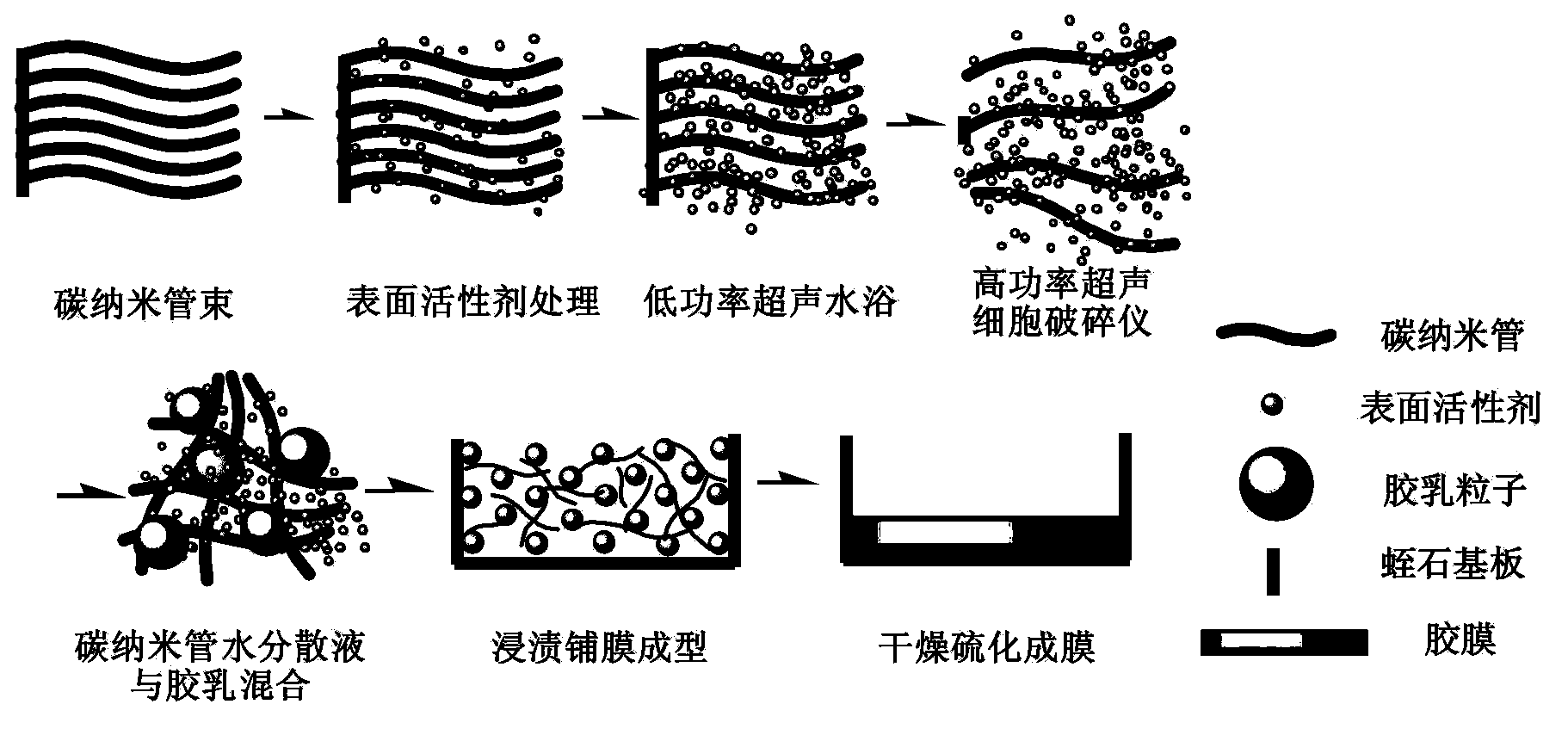

[0032] Take 0.27 parts of carbon nanotube bundles (0.25 parts of carbon nanotubes are converted into carbon nanotubes by mass of carbon nanotube bundles × content of carbon nanotubes, wherein the diameter of carbon nanotubes is 8-10 nanometers, and the average length is 50-100 microns), 0.5 parts of dodecane The carbon nanotubes were preliminarily dispersed in 62.5 parts of deionized water by vibrating in a 100W ultrasonic water bath for 30 minutes, and the carbon nanotubes were dispersed in deionized water as a single tube by ultrasonication with a 500W ultrasonic cell disruptor for 60 minutes.

[0033] Add the carbon nanotube dispersion to 95.9 parts of pre-vulcanized natural rubber latex (the composition containing pre-vulcanized natural rubber latex includes: 4.2 parts of vulcanization aids, 8.4 parts of emulsifiers), mix well, dip into the film, and dry at 40 ° C After 36 hours and 70°C vulcanization for 4 hours, the carbon nanotube bundle / natural rubber composite material...

Embodiment 2

[0038] Take 1.07 parts of carbon nanotube bundles (converted to 1 part of carbon nanotubes by mass of carbon nanotube bundles × 93%, the diameter of carbon nanotubes is 8-10 nanometers, and the average length is 50-100 microns), 4 parts of sodium lauryl sulfate, The carbon nanotubes were preliminarily dispersed in 250 parts of deionized water by shaking in a 200W ultrasonic water bath for 20 minutes, and the carbon nanotubes were dispersed in deionized water as a single tube by ultrasonication for 40 minutes by an 850W ultrasonic cell disruptor.

[0039] Add the carbon nanotube dispersion to 201 parts of pre-vulcanized natural rubber latex (the composition containing pre-vulcanized natural rubber latex includes: 8.35 parts of vulcanization aids, 25.05 parts of emulsifiers), mix well, dip into the film, and dry at 50 ° C After 24 hours and 80°C vulcanization for 2 hours, the carbon nanotube bundle / natural rubber composite material was obtained after leaching and drying. The con...

Embodiment 3

[0043] Take 3.2 parts of carbon nanotubes through carbon nanotube bundles (the mass of carbon nanotube bundles × 94% is converted into 3 parts of carbon nanotubes, the diameter of carbon nanotubes is 8-10 nanometers, and the average length is 50-100 microns), 15 parts of dodecyl Sodium sulfate, the carbon nanotubes were preliminarily dispersed in 750 parts of deionized water by shaking in a 300W ultrasonic water bath for 10 minutes, and the carbon nanotubes were dispersed in deionized water as a single tube by ultrasonication of 1000W ultrasonic cell disruptor for 10 minutes.

[0044] Add the carbon nanotube dispersion to 293 parts of pre-vulcanized natural rubber latex (the composition containing pre-vulcanized natural rubber latex includes: 16.7 parts of vulcanization aids, 66.8 parts of emulsifiers), mix well, dip into the film, and dry at 60 ° C for 18 hours, 100°C vulcanization for 0.5 hours, and then leaching and drying to prepare carbon nanotube bundles / natural rubber co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com