High-energy-efficiency hollow magnetic torquer design method and manufacturing process

A technology of a magnetic torque device and a design method, which is applied in the direction of the guidance device of the aerospace vehicle, etc., can solve the problems of large remanence of the magnetic rod-type magnetic torque device, increase the quality of the magnetic torque device, and high requirements on the material of the magnetic core, and achieve the output magnetic torque. Large moment, reduced mass, and the effect of overcoming large remanence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

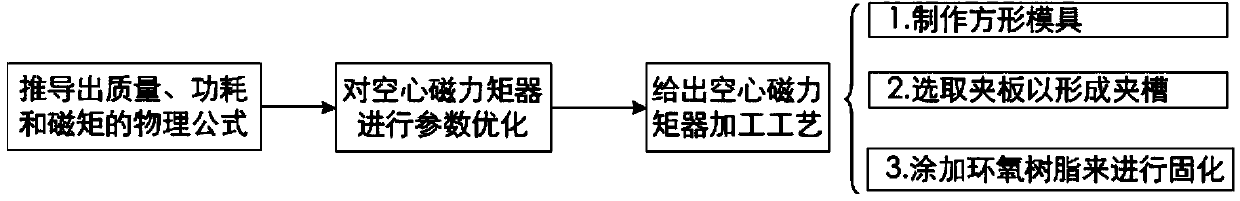

[0028] The specific process is as figure 1 shown.

[0029] 1. Deduce the physical formulas of mass, power consumption and magnetic moment

[0030] Before deriving the physical formulas of the mass, power consumption and magnetic moment of the magnetic torquer, the symbols to be used are defined as follows:

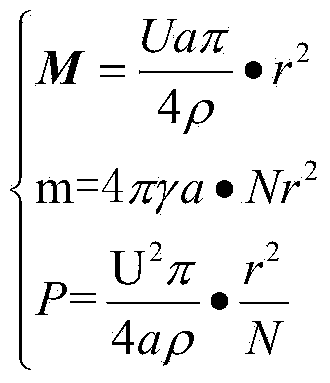

[0031] The magnetic moment of the magnetic torque device is M, the mass is m, the power consumption is P, the supply voltage is U, the current intensity of the current is I, the resistance R of the magnetic torque device, the unit normal vector n perpendicular to the surface of the magnetic torque device, and the magnetic force The average side length of the torque device is a, the volume of the magnetic torque device is V, the average area surrounded by the magnetic torque device is A, the resistivity of the wire is ρ, the density of the wire is γ, the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com