Onboard power generation equipment of unmanned aerial vehicle

A technology of power generation equipment and drones, applied in the field of drones, can solve problems such as difficulty, confusion of data parameters, and heavy weight of onboard power generation devices, and achieve the effects of improving power supply status, ensuring work performance, and stable and reliable signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

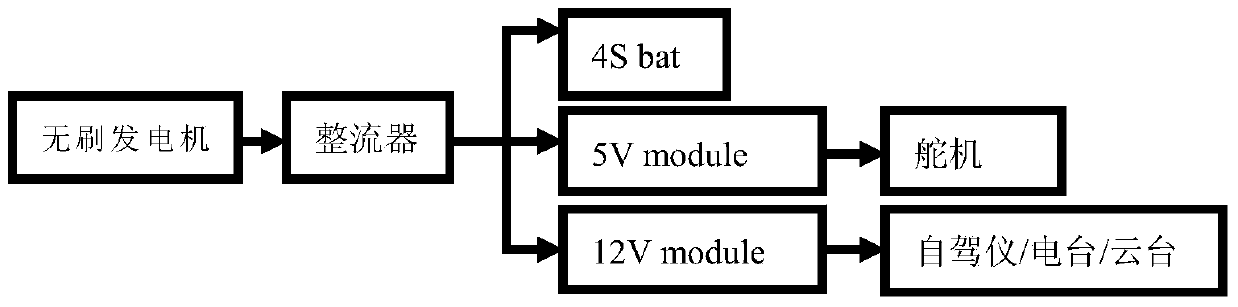

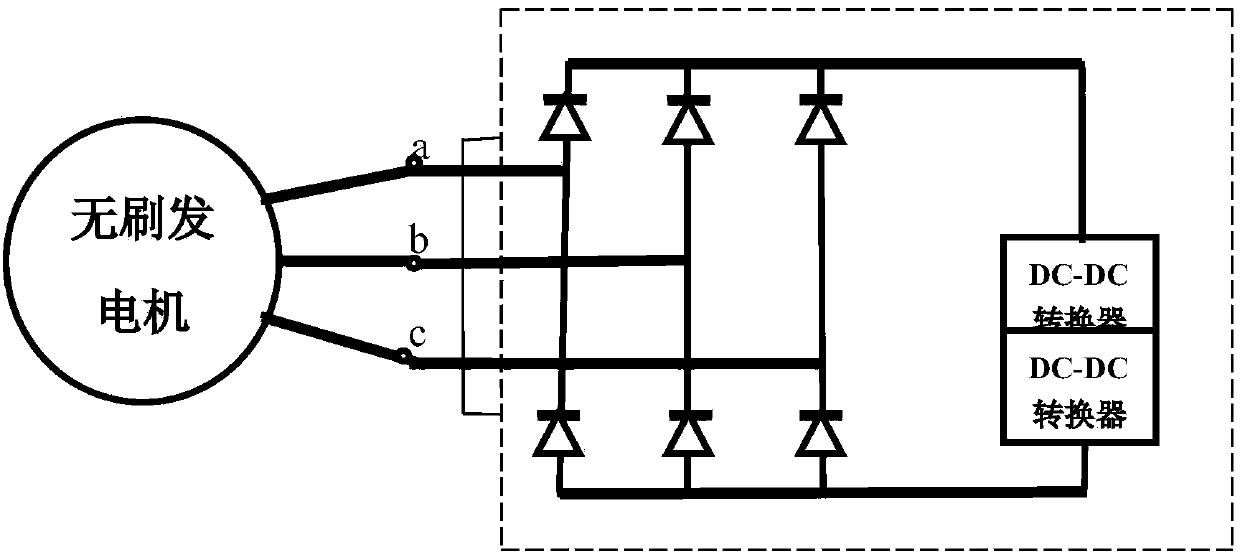

Method used

Image

Examples

example

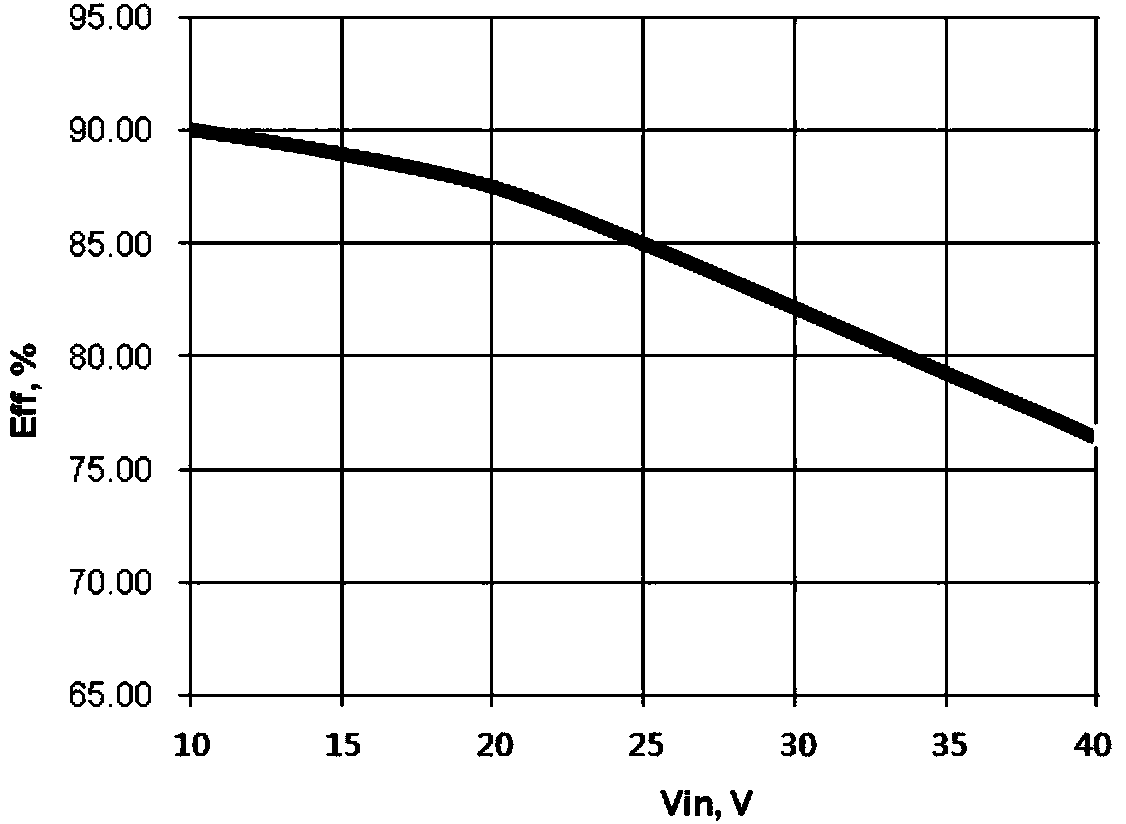

[0045] Example: A toothed belt drives a generator, the gear ratio between the two gears can be chosen to keep the input voltage of the on-board power generation unit (AGPU) within the 36V limit. In many cases, the low engine RPM results in a voltage lower than 12V, which means that the backup battery will power the UAS, and the UAV flying at low speed will be powered by the backup battery for the extra time. According to the actual flight mission, the capacity of the battery needs to be calculated. Battery capacity (Ah) = working time (h) * average load power (W) / battery voltage (V) / 0.8.

[0046] In the present invention, the on-board power generation unit (AGPU) has two electronic aviation interfaces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com