UFO-type vertical take-off and landing hypersonic jet stealth aircraft

A vertical take-off and landing, hypersonic technology, applied in vertical take-off and landing aircraft, flying saucers, jet propulsion devices, etc., can solve the problems of easy air accidents, complex structure, energy consumption, etc., and achieve large thrust, large space, and large carrying capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

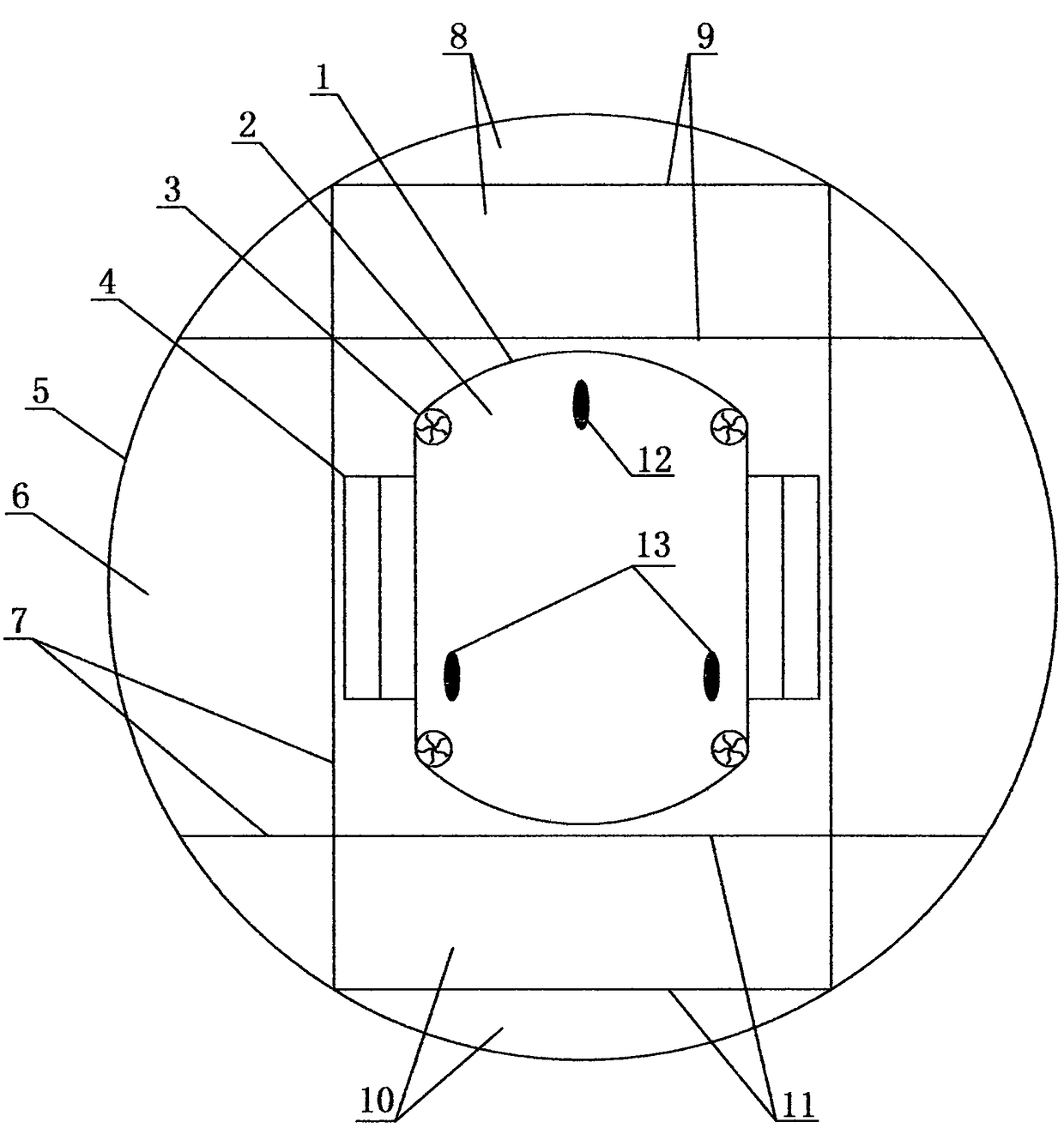

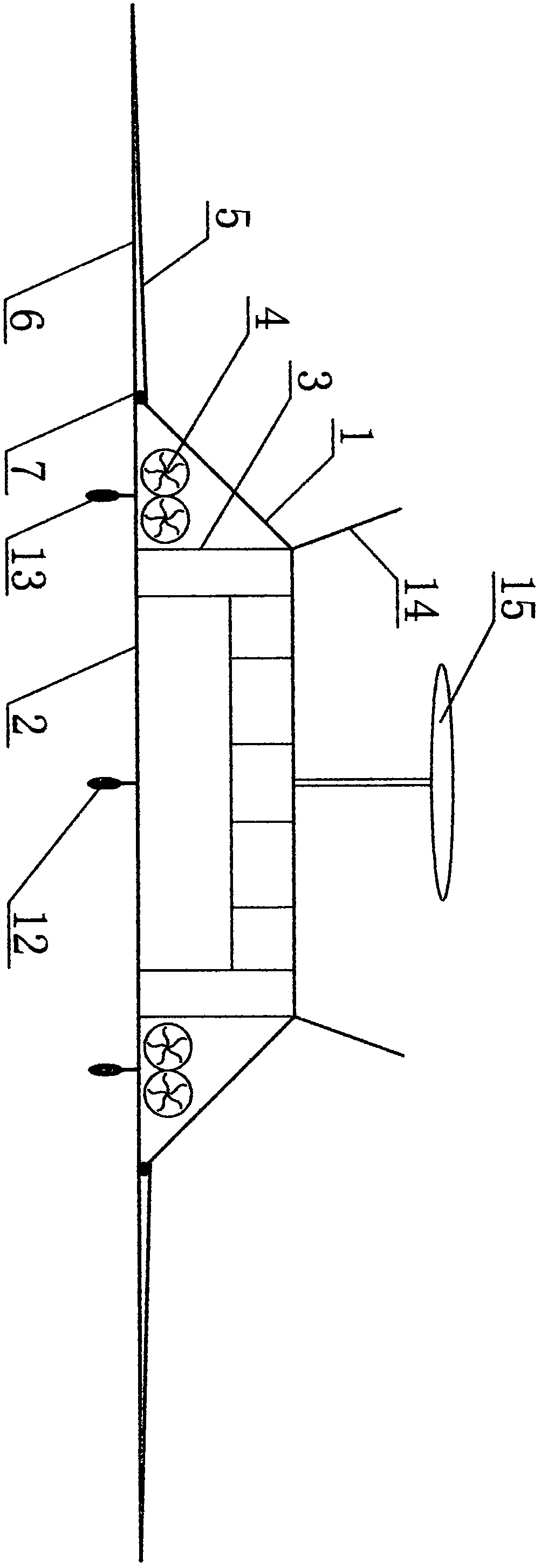

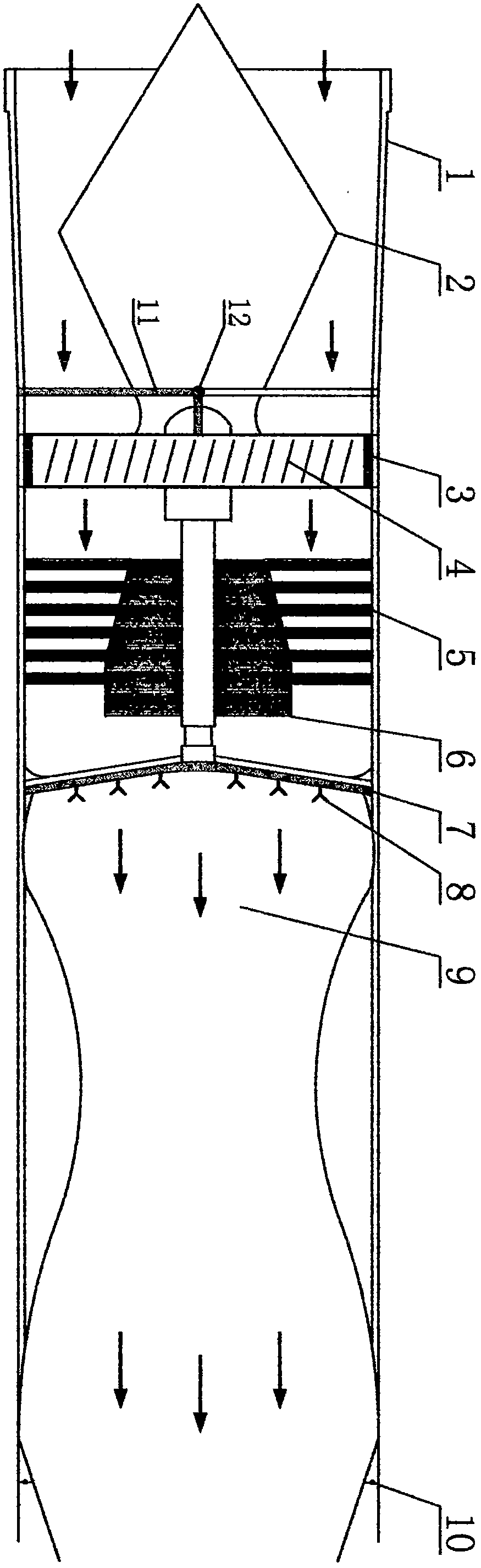

[0015] like figure 1 , 2Shown, a flying saucer type vertical take-off and landing hypersonic jet stealth aircraft, it comprises body 1, chassis 2, vertical take-off and landing without turbojet engine 3, propulsion without turbojet engine 4, annular wing 5, side wing 6, Side wing implement rotating shaft 7, front wing 8, front wing rotating shaft 9, rear wing 10, rear wing rotating shaft 11, front landing gear, prop wheel 12, rear landing gear, prop wheel 13, vertical wing 14. Radar antenna 15, computers, wires, oil pipes, air pipes, oil pumps, air pumps, display screens, joysticks, instruments, signal lights, electronic switches, design the aircraft as a flying saucer, design the body 1 as invisible or streamlined, and the engine Designed as a turbine-free type, an annular wing 5 is installed on the periphery of the chassis 2 of the body 1, and the annular wing 5 is divided into four parts, which is beneficial to folding or unfolding the wings, and a front wing 8 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com