Stamping die set for harvester picker jaws

A stamping die and pick-up technology, applied in the field of stamping die sets, can solve the problems of insufficient bending angle, uneven bending, bending damage, etc., and achieve the standard of flat bending surface, not easy to bend and break, and bending angle. precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In the following, the specific implementation manners of the present invention will be further described in detail in conjunction with the accompanying drawings of the embodiments, so as to make the technical solution of the present invention easier to understand and grasp.

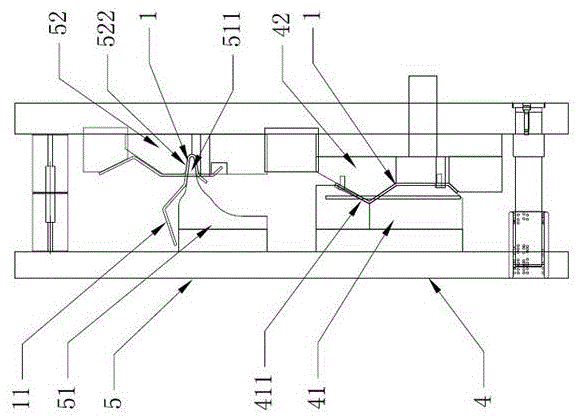

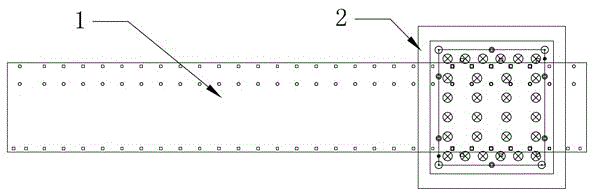

[0016] Such as Figure 1 to Figure 4 As shown, the stamping die set of the claw of the harvester picker involves the processing part 1 of the claw. In particular, the stamping die set consists of a positioning hole stamping unit 2, a notch stamping unit 3, a first bending stamping unit 4 and a second The bending stamping unit 5 is composed of, wherein, the first bending stamping unit 4 includes a matching bending stamping block 41 and a bending stamping seat 42, and the second bending stamping unit 5 includes a forming stamping block 51 and a forming stamping seat 52, The bearing surface of the forming stamping seat 52 matches the stamping surface 411 of the bending stamping block 41, and the beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com