Method for preparing egg essence by using maillard reaction

A Maillard reaction, egg technology, applied in food preparation, application, acid-containing food ingredients, etc., can solve the problems of rarity and insufficient fullness of flavor, and achieve good high temperature resistance, high safety, broad market prospects and economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

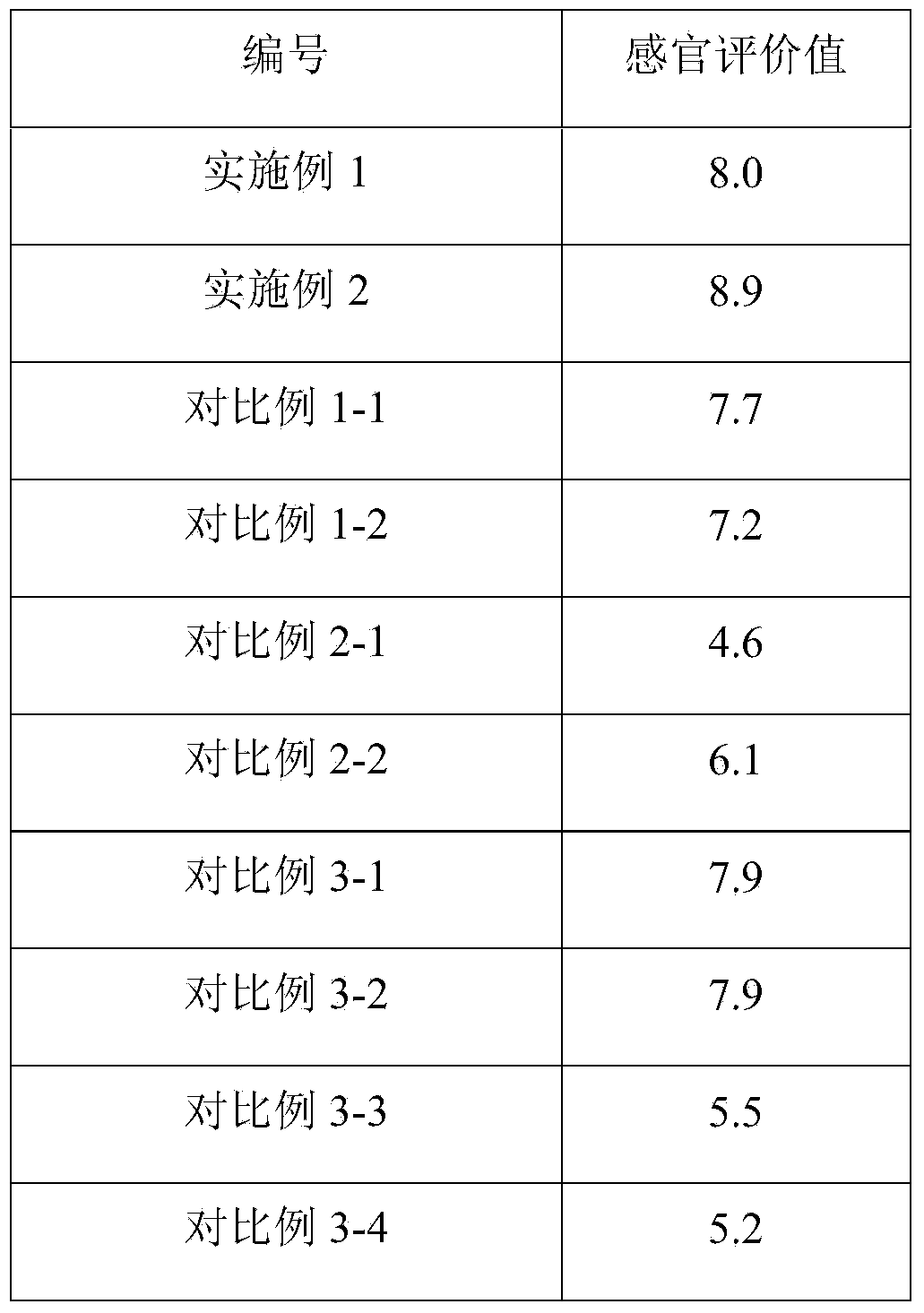

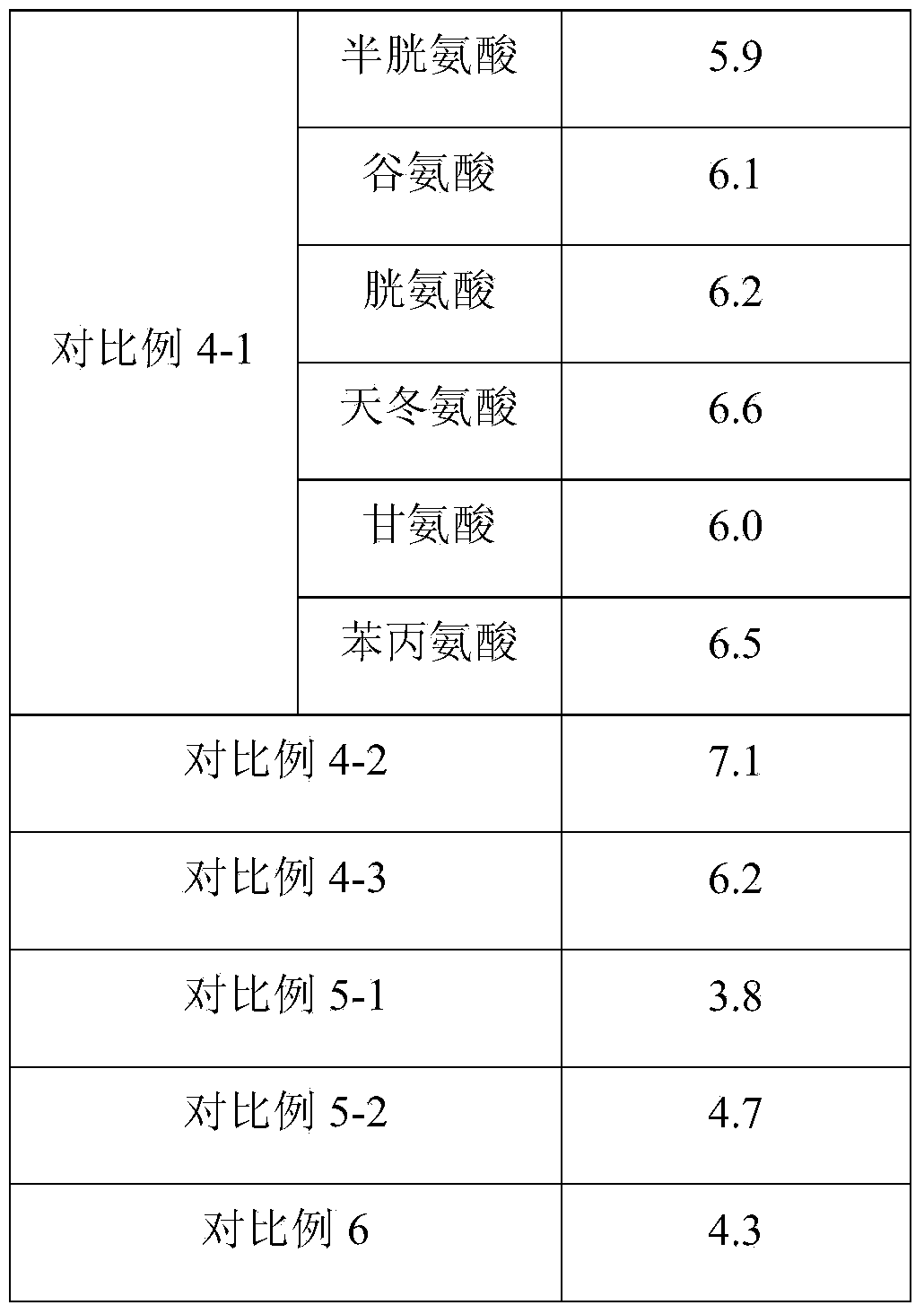

Examples

Embodiment 1

[0023] Embodiment 1, a kind of method utilizing Maillard reaction to prepare egg essence, carries out following steps successively:

[0024] 1) After shelling the eggs, beat them into a slurry, weigh 100g of the slurry, add 900g of water, mix well, and obtain the egg liquid;

[0025] First use a sodium hydroxide solution with a concentration of 1.0N to adjust the pH of the egg liquid to 8.0, then heat it in a water bath at 80°C for 10 minutes; then cool it to room temperature (cooling can be achieved by running water), and then add 0.5g of Novozymes food-grade alkali Protease Alcalase 2.4L, stirred evenly, enzymatically hydrolyzed in 55°C constant temperature water bath at 200rpm for 2.0h,

[0026] After hydrolysis, raise the temperature to 90°C and keep it for 15 minutes, the purpose is to inactivate the protease; then after reaching room temperature (cooling with running water can be used), filter (pass through a 1.2μm filter membrane), and the obtained filtrate is concentra...

Embodiment 2

[0029] Embodiment 2, a kind of method utilizing Maillard reaction to prepare egg essence, carries out following steps successively:

[0030] 1) After shelling the eggs, beat them into a slurry, weigh 200g, add 800g of water, mix well, and obtain egg liquid;

[0031] First use 1.0N sodium hydroxide solution to adjust the pH of the egg liquid to 8.0, place it in a water bath at 80°C and heat it for 10 minutes, take it out and cool it to room temperature; then add 0.8g Novozymes food-grade alkaline protease Alcalase 2.4L, After stirring evenly, enzymatically hydrolyze for 3.0 hours in a constant temperature water bath at 55°C and stir at 200rpm;

[0032] After the hydrolysis, the solution was warmed up to 90°C and kept for 15 minutes in order to inactivate the protease, then cooled to room temperature, filtered (passed through a 1.2 μm filter membrane), and the obtained filtrate was concentrated to one third of its volume by rotary evaporation at 60°C in vacuum , stop concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com