housing for electronic devices

A technology for electronic devices and housings, which is applied to electrical equipment shells/cabinets/drawers, electrical components, etc., can solve problems such as product qualification rate and thermal shrinkage inconsistency that affect the visual effect of electronic device housings, and achieve improved appearance and improved appearance. The effect of pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

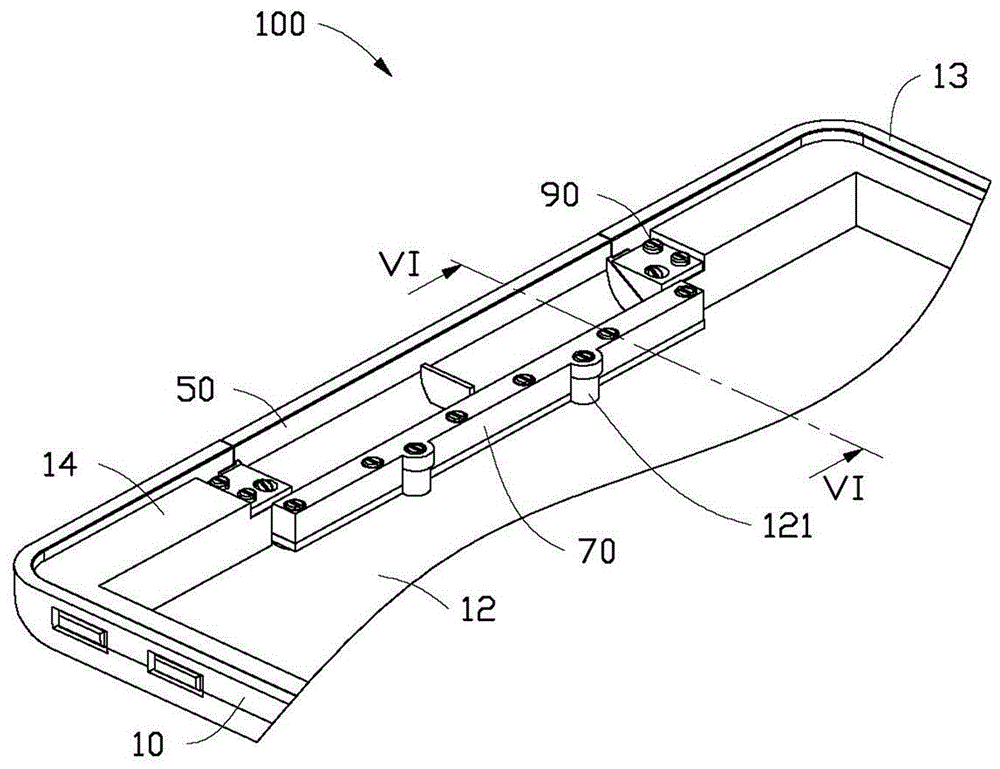

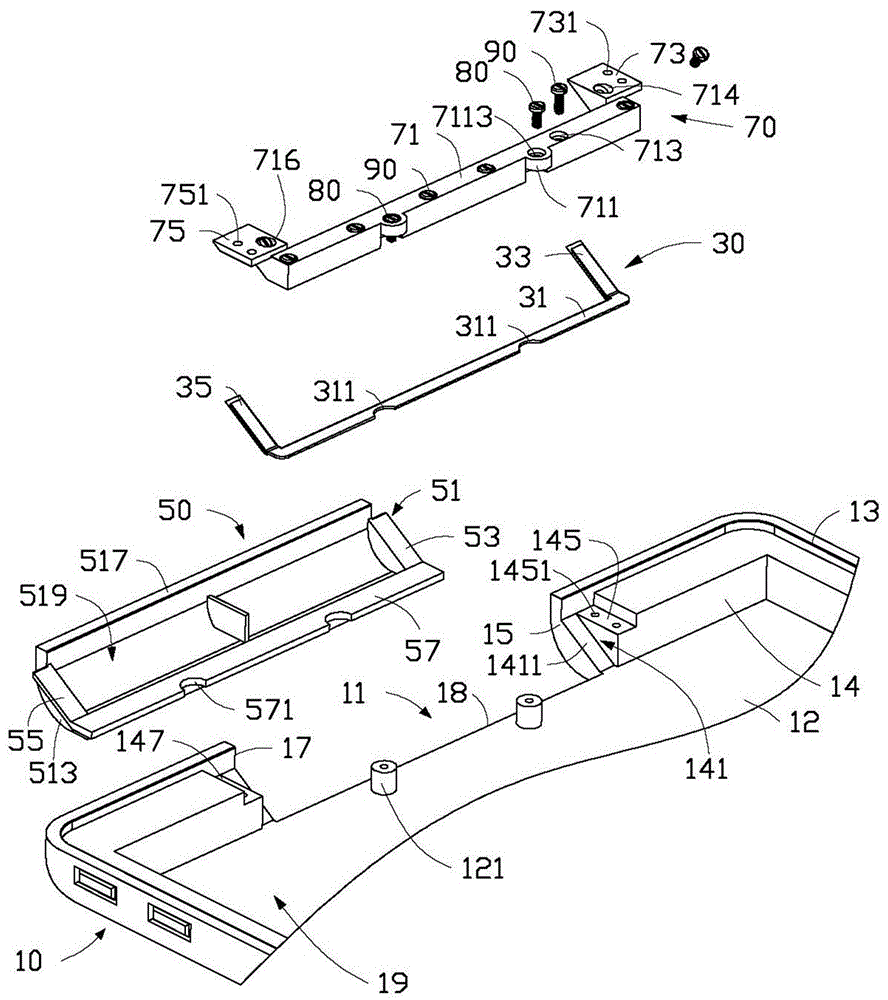

[0017] see figure 1 and figure 2 , the housing 100 of the electronic device according to the embodiment of the present invention, which includes a first housing 10 having an opening 11, an elastic member 30 installed on the first housing 10, and an elastic member 30 installed on the first housing 10. The second housing 50 on the top, the pressing member 70 installed on the first housing 10 and located on the second housing, the fastener 80 fixing the first housing 10 and the pressing member 70, and passing through the pressing member The member 70 and abuts against the adjusting member 90 of the second housing 50 . In this embodiment, the first casing 10 is made of metal material, and the second casing 50 is made of plastic material.

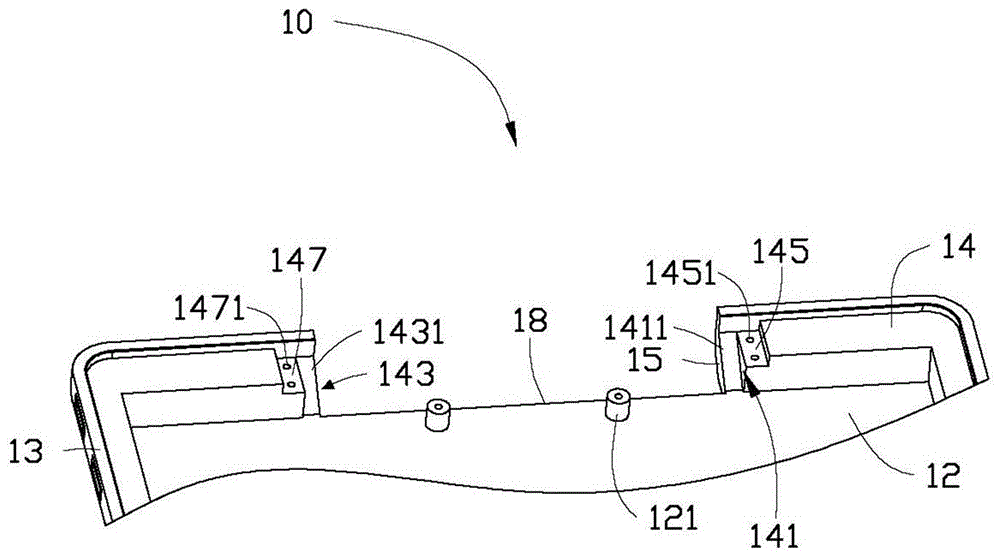

[0018] Please refer to image 3 , the first housing 10 is provided with an opening 11 . The first housing 10 includes a bottom wall 12 , a side wall 13 bent and extended from the periphery of the bottom wall 12 , and a protrusion 14 formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com