Waterproof structure and mobile phone using the waterproof structure

A technology of waterproof structure and shell, applied in the direction of telephone structure, sealed shell, etc., can solve the problems of increasing cumulative tolerance, unable to guarantee manufacturing tolerance, and low yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the purpose, technical solution and advantages of the present invention more clear, the waterproof structure of the present invention and the mobile phone using the waterproof structure will be further described below in conjunction with the drawings and specific embodiments.

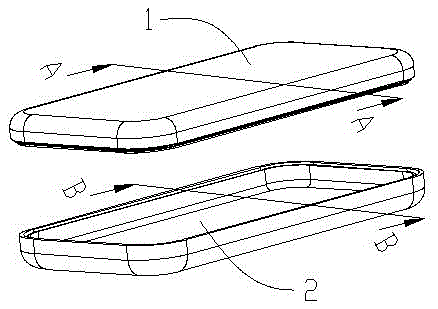

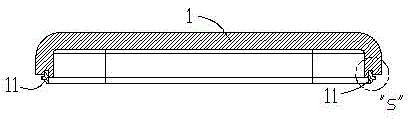

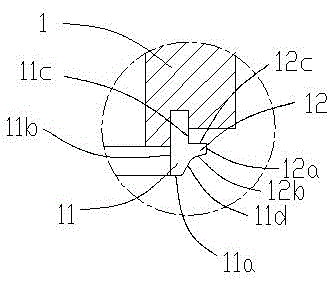

[0016] Please refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , which is a mobile phone waterproof structure embodiment, the mobile phone includes a front shell 1 and a rear shell 2, the front shell 1 is provided with a soft material protrusion structure 11, the soft material protrusion mechanism 11 and The front shell 1 is integrally double-shot molded, and the raised structure 11 includes a first top surface 11a, a first inner surface 11b, and a first outer surface 11c, and the first outer surface 11c is close to the first top surface 11a for ease of assembly And set a guide slope 11d, on the first outer surface 11c of the protruding structure 11, a bump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com