Visual minitype fluid cavitation testing device

A test device and cavitation technology, which is applied in the field of aerospace and refrigeration cryogenic engineering, can solve the problems of large cryogenic fluid, unsuitable miniaturized experimental research, complex structure, etc., and achieve stable performance, good heat insulation effect, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

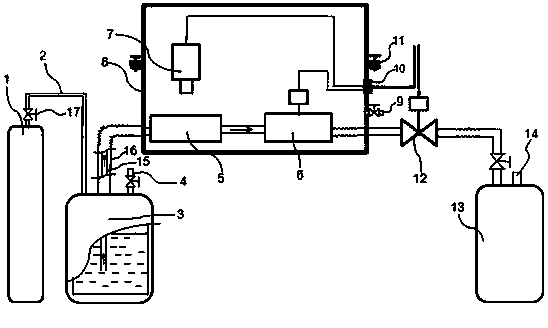

[0031] The following is a detailed description of the visualized small-scale fluid cavitation testing device of the present invention in conjunction with the accompanying drawings.

[0032] Such as figure 1 Shown is the visualized small fluid cavitation test device of the present invention, in the figure, the high-pressure gas tank 1 communicates with the test medium storage tank 3 through the air guide tube 2, and the test medium storage tank 3 communicates with the cavitation component 5 through the infusion tube 15, and the steam Corrosion part 5 is communicated with flowmeter 6 by the pipeline of horizontal placement, and flowmeter 6 is connected with the recovery bottle 13 in the recovery unit by pipeline;

[0033] In order to ensure the stability and controllability of the low-temperature liquid pressure source, preferably, a high-pressure gas tank 1 with a valve 17 is used as the pressure source.

[0034] One end of the infusion tube 15 communicates with the cavitation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com