Device and method for malfunction treatment of refrigerator probes

A processing method and refrigerator technology, which are applied to household refrigeration devices, lighting and heating equipment, household appliances, etc., can solve problems such as probe failure, disconnection of sensor temperature sensing devices, errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with accompanying drawing:

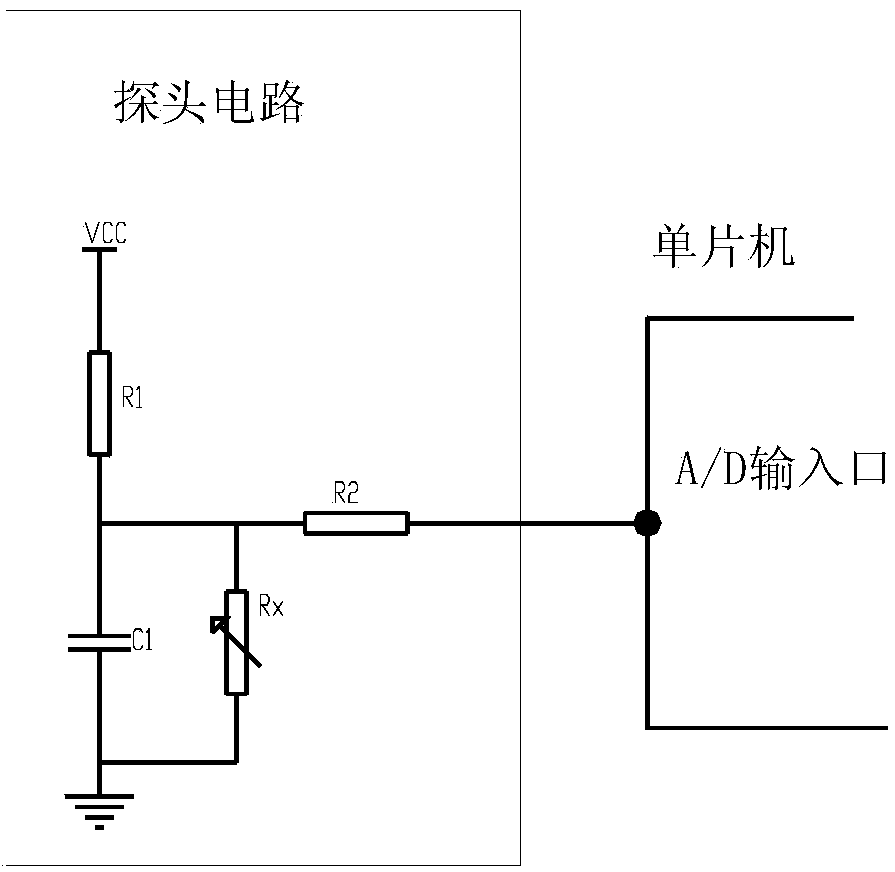

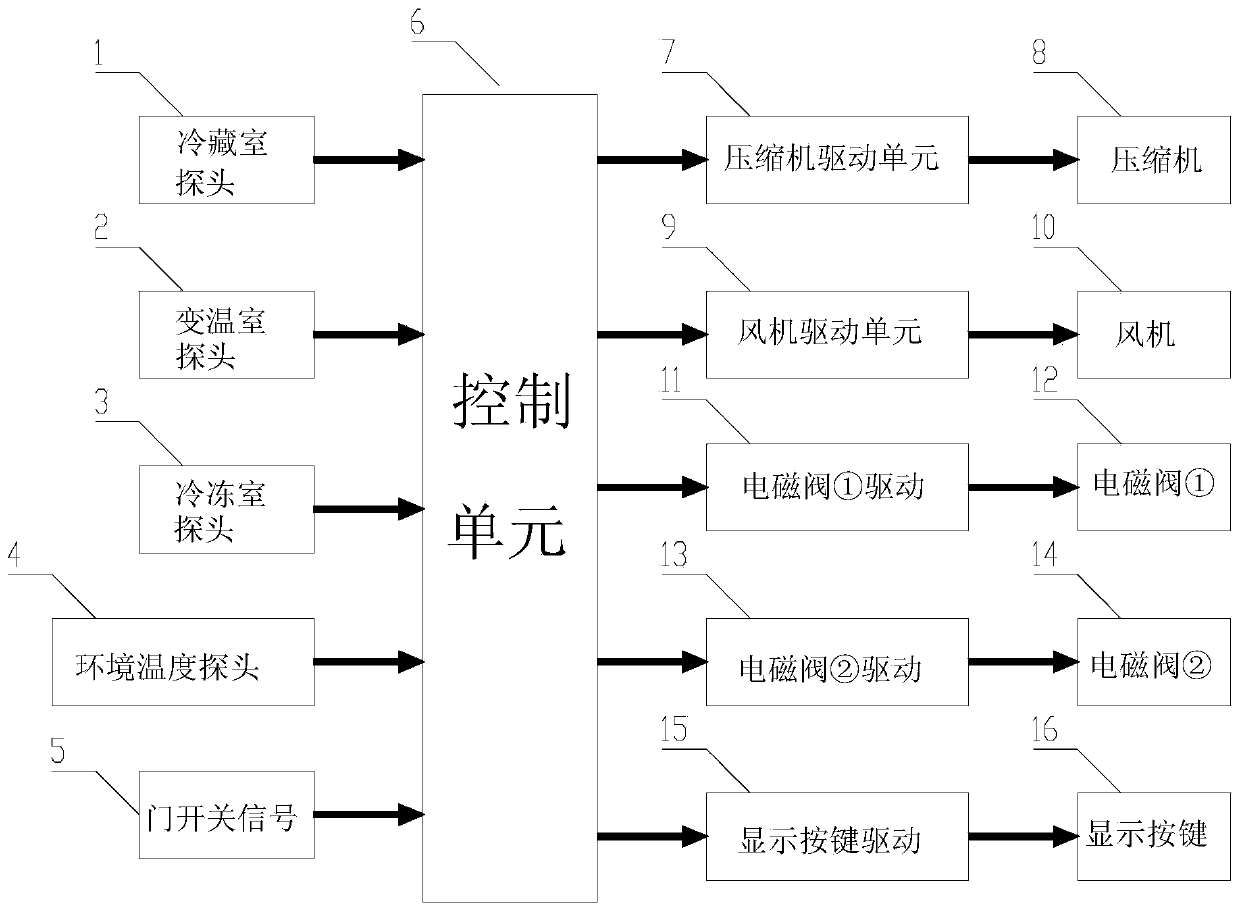

[0023] figure 2 For adopting the control block diagram of the device of the present invention, the control system adopting the single-chip processor 6 as the core includes a detection unit connected with the single-chip processor 6: a refrigerating room temperature probe 1, a variable temperature room temperature probe 2, and a freezing room temperature probe 3 , ambient temperature probe 4, door switch signal and detection circuit 5; said single-chip processor 6 also drives compressor 8, blower fan 10, solenoid valve 1. 12, solenoid valve 2. 14 through drive circuit; and display button drive circuit 15 drives display button 16. Probes can use negative temperature coefficient (NTC) thermistors, direct heating thermistors, direct heating NTC thermistors, insulated thermistors, etc.

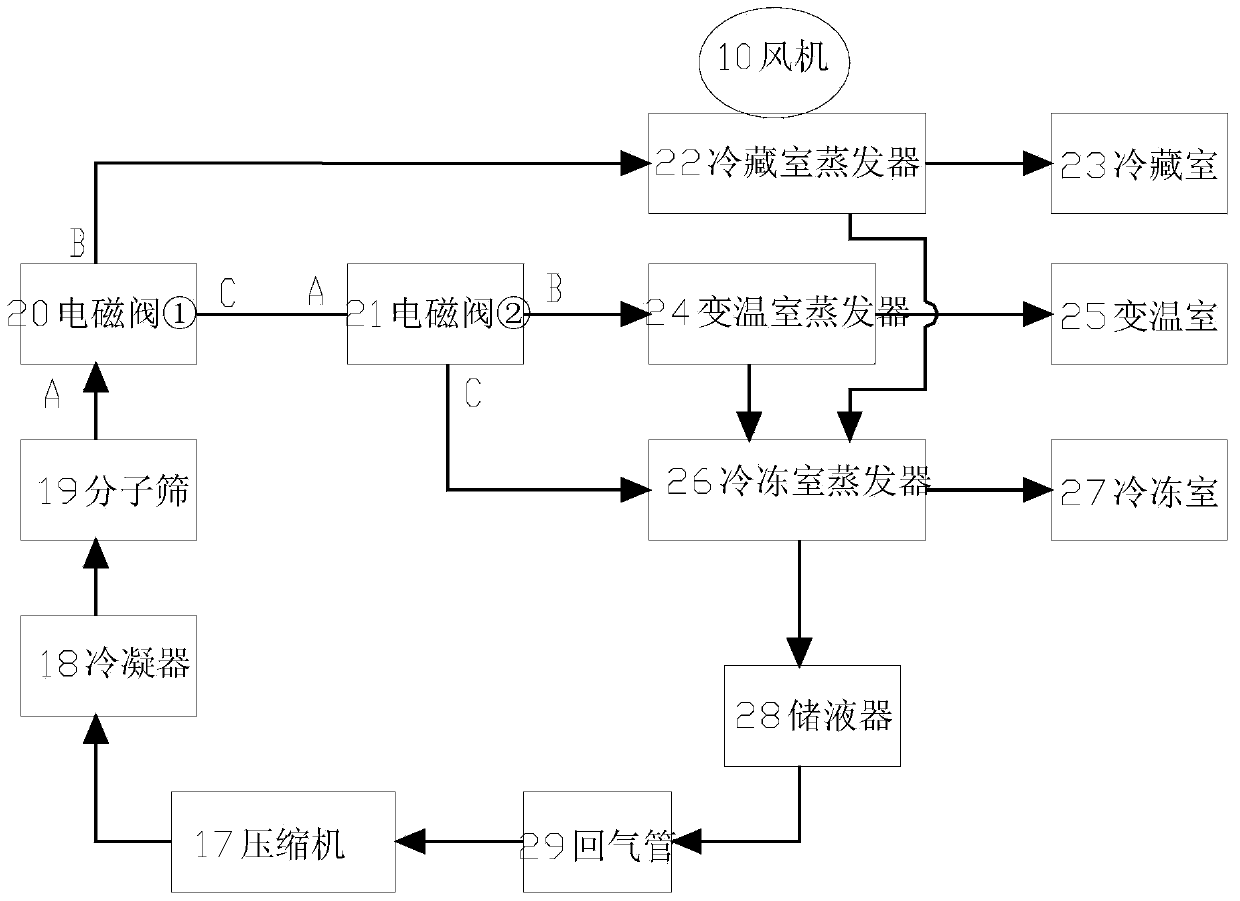

[0024] image 3 In order to adopt the refrigeration flow chart of the device of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com