Structure reinforcing method in externally-attached steel-encased assembly type PC frame mode

A technology for strengthening structures and outsourcing steel, applied in building construction, building maintenance, construction, etc., can solve the problems of lack of connection between old and new concrete, increase the seismic performance of the structure, and cannot form a whole, so as to achieve flexible layout and improve resilience. , Good anti-seismic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

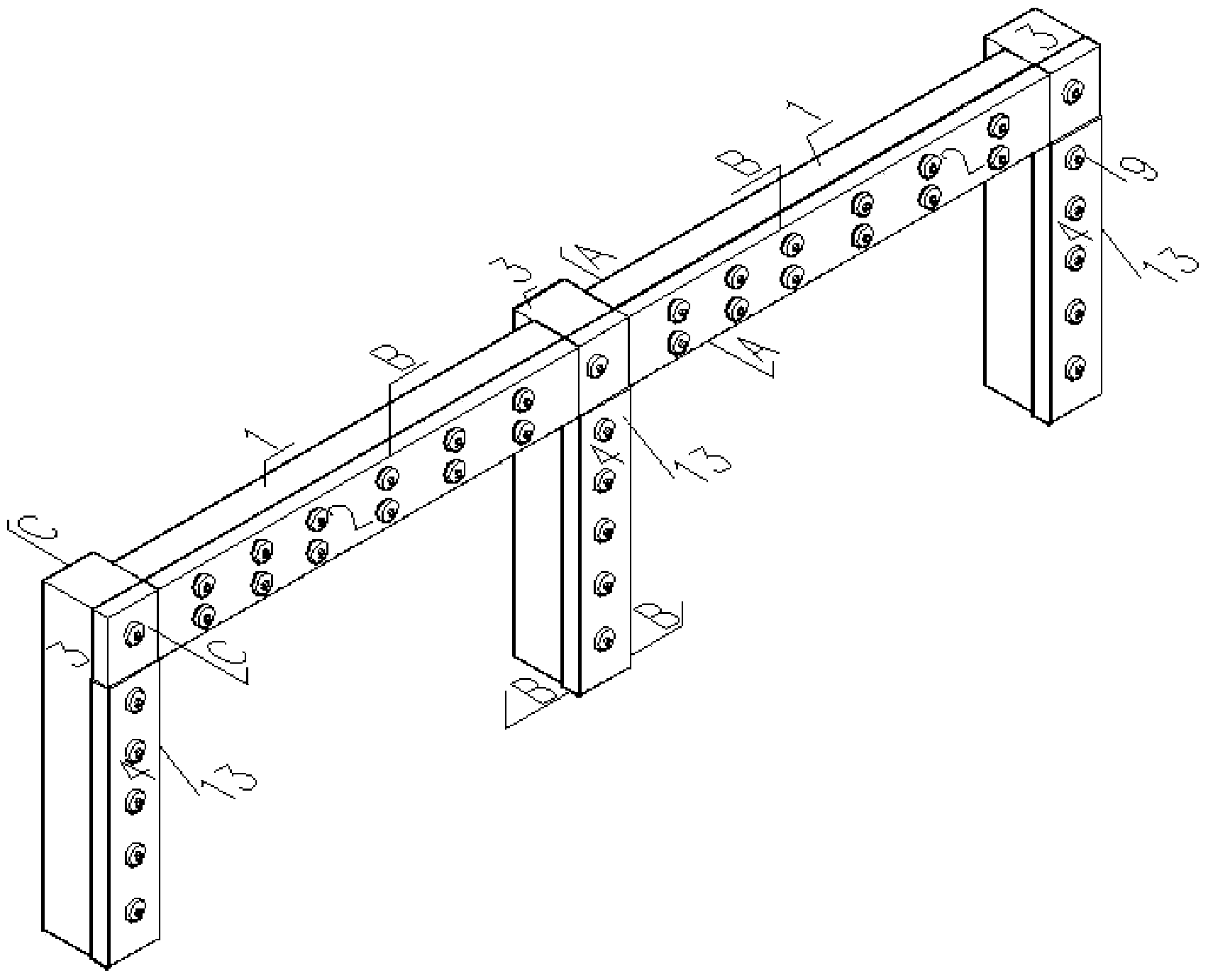

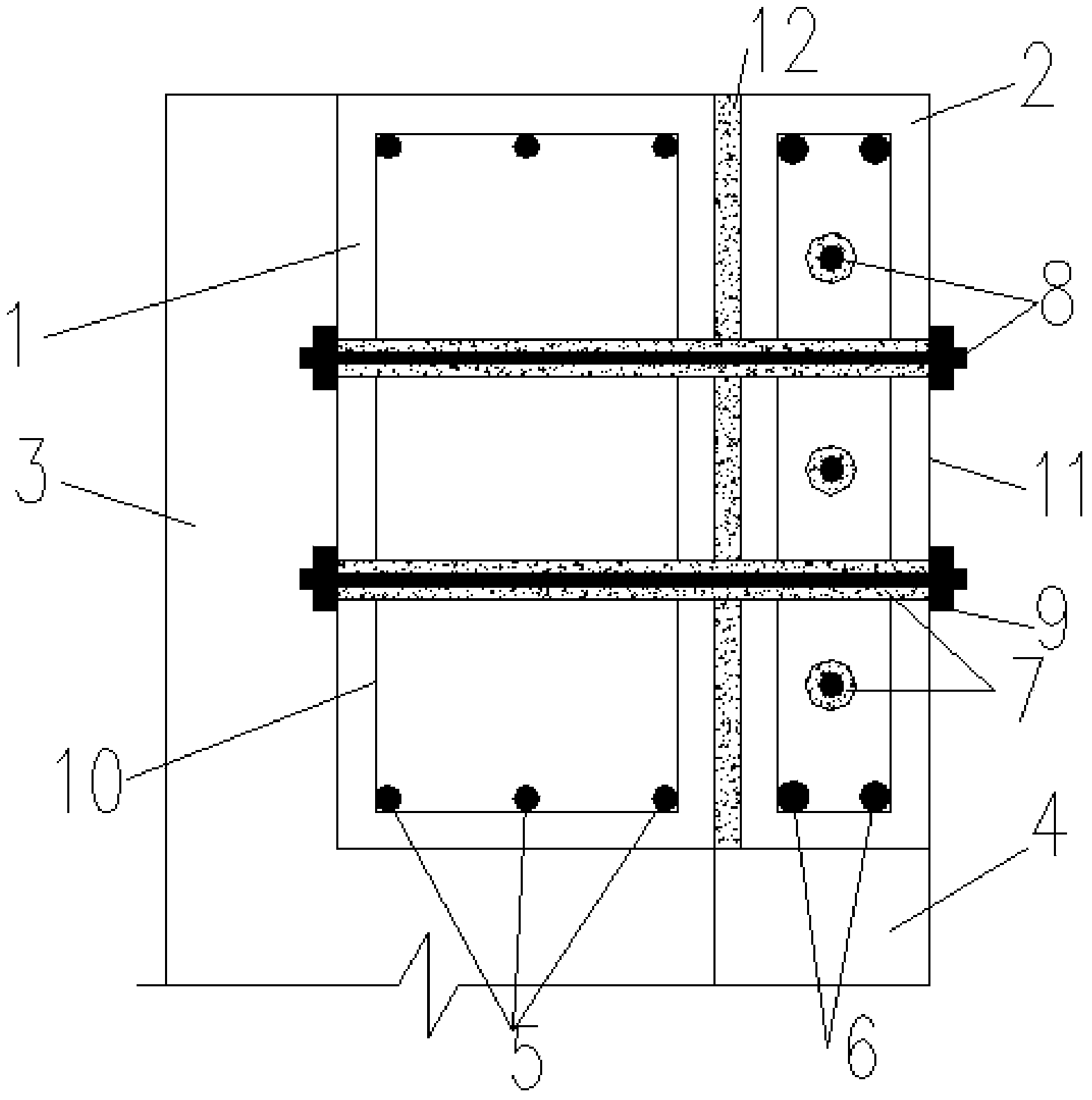

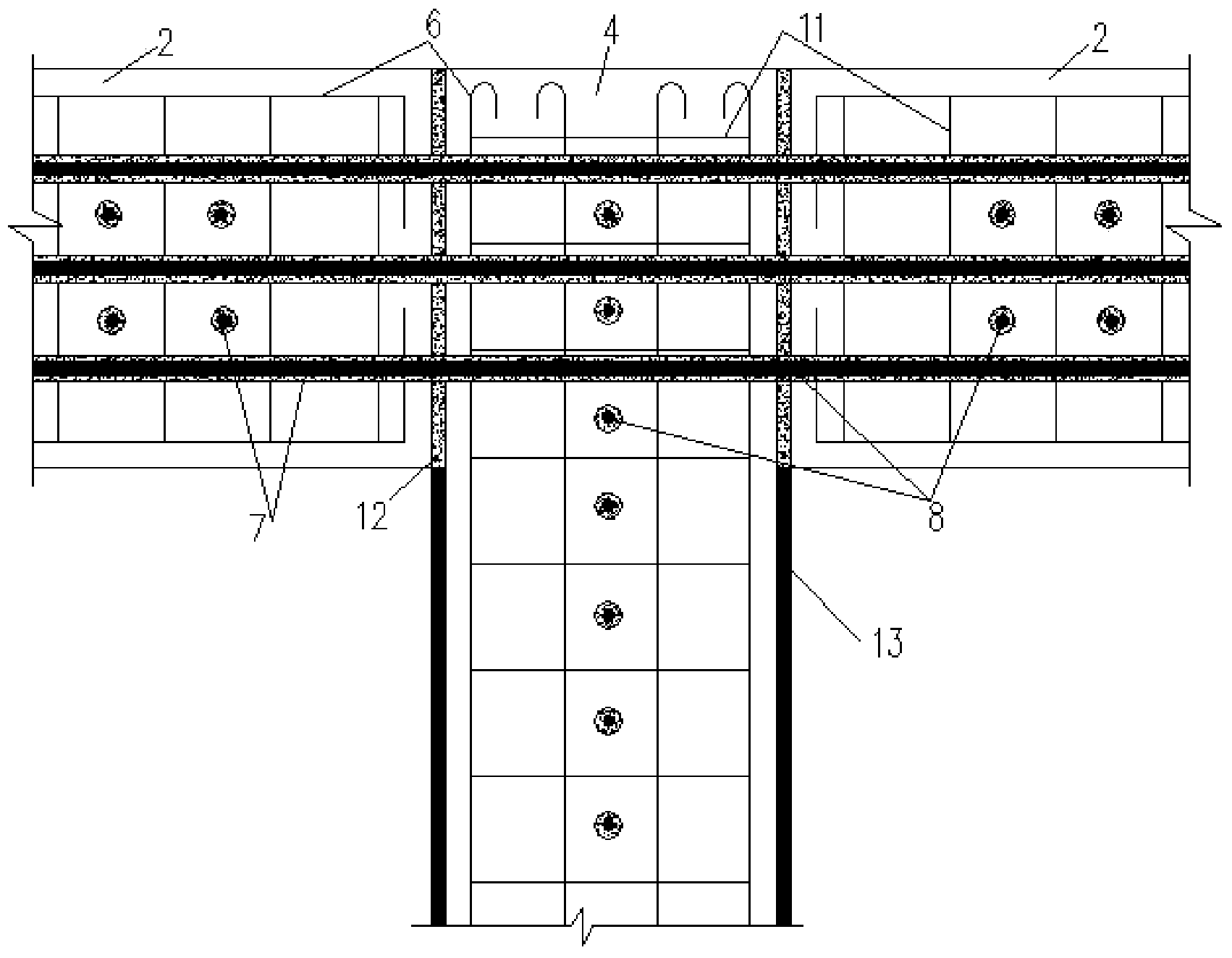

[0029] The specific construction method, taking the application in the frame beam as an example:

[0030] In this example, the size of the original frame beam is 150mm×300mm, the strength grade of the concrete used is C35, the strength grade of the steel bar is HRB335, the size of the external prefabricated beam is 100mm×300mm, the strength grade of the concrete used is C40, and the strength grade of the steel bar is HRB400, the prestressed tendon adopts 1×7, the diameter is 12.7, and the strength is f ptk =1860N / mm 2 , f py =1320N / mm 2 , The steel plate is made of 5mm thick Q345 steel. According to the analysis results of the model, it is shown that Figure 4 , Compared with the unreinforced, the bearing capacity is increased by nearly 50%.

[0031] a. Design and manufacture

[0032]According to the section size of the original reinforced concrete frame beam 1, the newly added prefabricated reinforced concrete frame beam 2 section is designed. Submit the design results...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com