Hot air circulating pre-oxidation furnace

A technology of pre-oxidation furnace and hot air circulation, which is applied to the chemical characteristics of fibers, textiles and papermaking, etc. It can solve the problems of high operating cost and high heating energy consumption, achieve low operating cost, reduce energy loss, and prevent the burning of raw silk Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

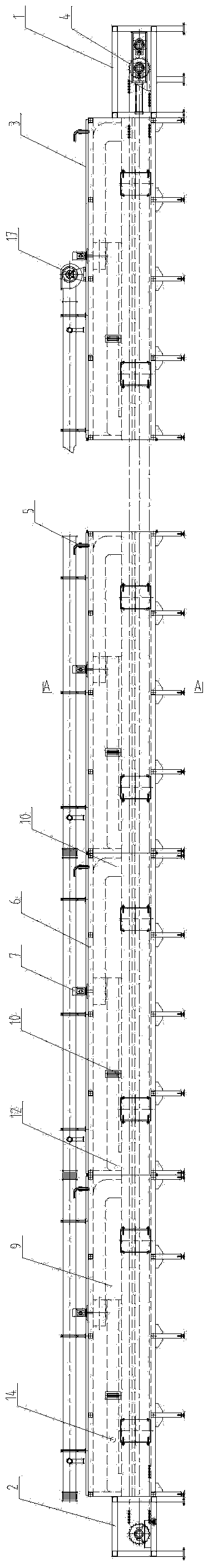

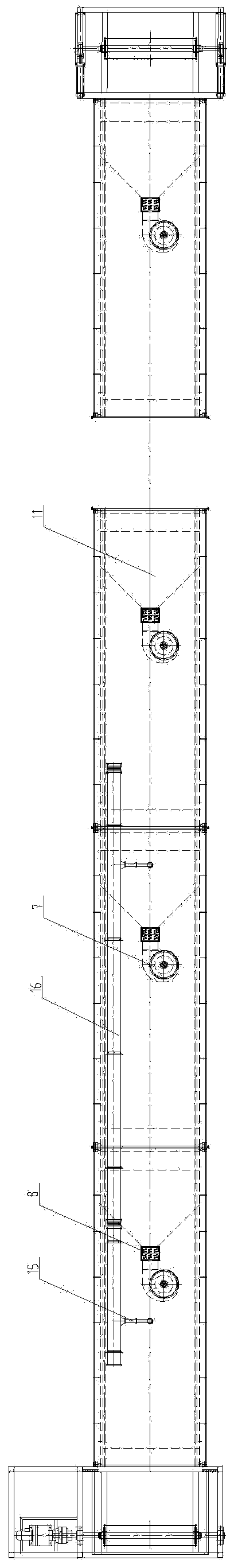

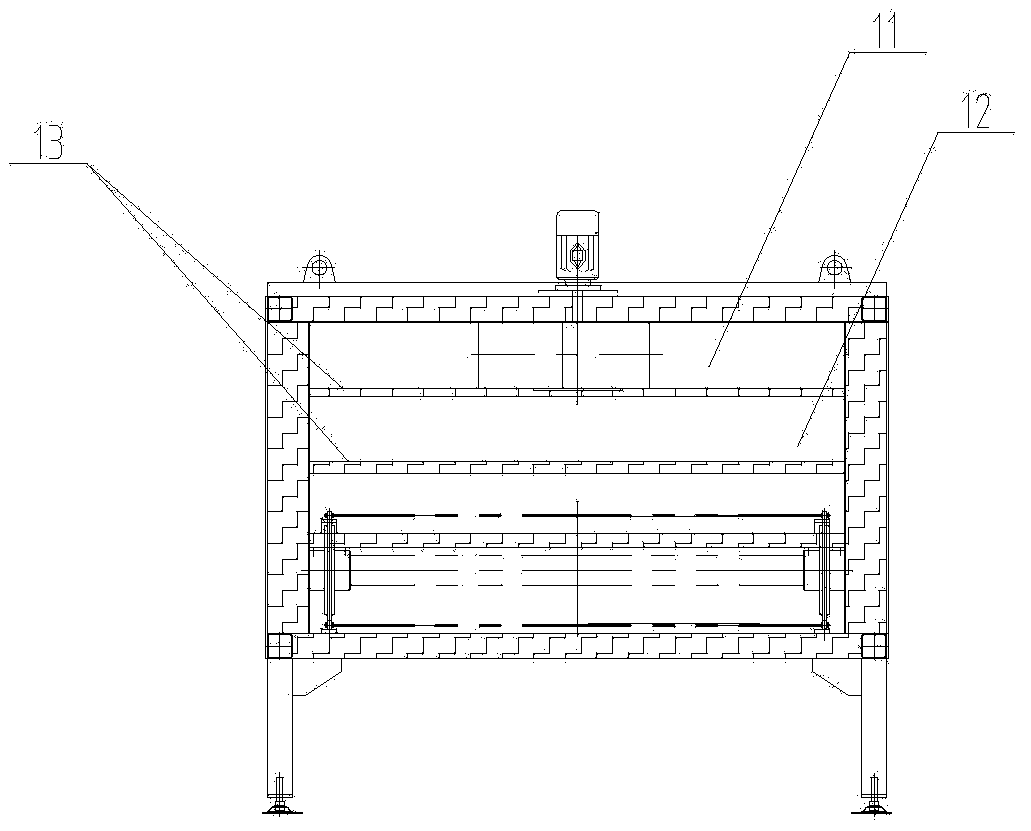

[0020] combine Figure 1-3 A hot air circulation pre-oxidation furnace shown in , adopts a built-in hot air circulation heating method, including front and rear racks 1, 2, furnace body 3, mesh belt chain transmission mechanism 4, exhaust system, nitrogen atmosphere system 5, electrical As for the control system and the multiple heating zones 6 arranged in the furnace body 3, each heating zone 6 is provided with an independent hot air circulation system.

[0021] Concrete each hot air circulation system has the same structure, including high temperature resistant circulation fan 7, air heater 8, internal circulation air duct 9 and air filter 10, and its air heater 8 is arranged on the air inlet of internal circulation air duct 9, The air filter 10 is arranged at the air outlet of the internal circulation air duct 9, and its circulation fan 7 is connected with the air inlet and return air outlet of the internal circulation air duct 9. Among them, the circulating fan 7 adopts a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com