Mining filling cementing material ratio decision-making method

A technology of cementitious materials and decision-making methods, applied in the decision-making field of proportioning, can solve problems such as low efficiency and long time-consuming, and achieve the effect of high efficiency, small workload and realization of reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

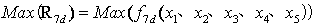

Method used

Image

Examples

Embodiment 1

[0034] Example 1 Proportion decision of cementitious materials for mining in Sijiaying Iron Mine

[0035] The Sijiaying mining area is located in the eastern Jidong Plain. Not only is it difficult to acquire land for the tailings pond, but also the surface does not allow subsidence. Therefore, the full tailings filling method is adopted for resource mining. In order to solve the economic benefit problem of iron ore full tailings filling mining, it is urgent to carry out the optimal decision-making of the ratio of iron ore full tailings filling cementitious materials. For this reason, adopt the inventive method to carry out the decision-making of the proportioning of cementitious material for mining with full tailings filling of Sijiaying Iron Mine, concrete implementation steps are as follows:

[0036] (1) Investigation and analysis of physical and chemical characteristics of full tailings filling material and industrial waste residue in Sijiaying Iron Mine, and selection of...

Embodiment 2

[0057] Example 2 Decision-making on the ratio of gelling agent for mixed filling materials of full tailings and rod frosted sand in Jinchuan Nickel Mine

[0058] The cemented filling method of Jinchuan Nickel Mine has always used rod abrasive filling. The mining cost of filling is high, and the whole tailings of the ore dressing cannot be used and are piled up in large quantities. The above problems can be solved by using the mixed filling material of rod scrub and full tailing sand. For this reason, adopt the inventive method to carry out the decision-making of the proportioning of Jinchuan Nickel Mine full tailings and rod frosted mixed filler filling cementitious material for mining, concrete implementation steps are as follows:

[0059] (1) Investigation and analysis of physical and chemical characteristics of full tailings and rod sand mixed filling materials and industrial waste residues in Jinchuan Nickel Mine, and selection of cementitious materials.

[0060] The ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com