Device and method for on-line viscosity detection of high temperature and high pressure oil-water mixed fluid

An oil-water mixed fluid, high temperature and high pressure technology, applied in the direction of measuring device, DC flow characteristic measurement, flow characteristics, etc., to achieve accurate and reliable measurement information, less equipment investment, and less lag time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

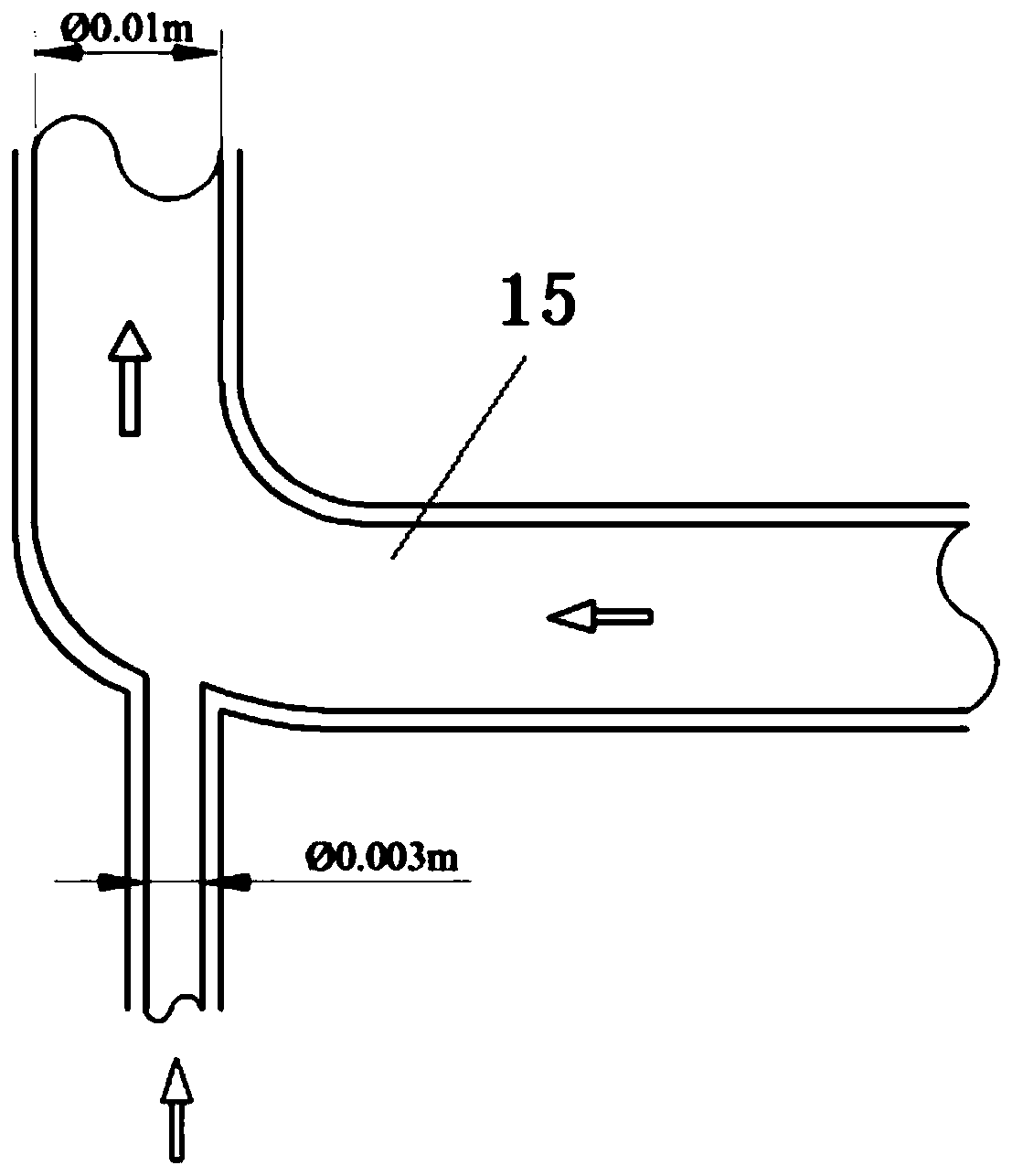

Image

Examples

Embodiment 1

[0047] Early preparation:

[0048] Prepare the oil-water two-phase mixed fluid sample of required gas-oil ratio in the first high-temperature and high-pressure container 11, close the first control valve 51, the second control valve 52, the third control valve 53 and the second valve 62, and the remaining control valves and The valves are fully opened, and the system is evacuated through the vacuum interface 154 .

[0049] After the vacuuming is completed, set the pressure of the back pressure valve 56 as the test pressure, open the first control valve 51 and the second control valve 52, and close the first valve 61, the fifth valve 65, the sixth valve 66, the seventh valve 67, The eighth valve 68 is used to inject the sample in the first high-temperature and high-pressure container 11 into the entire wellbore flow model system through the first injection pump 13, and continue to pressurize until the pressure of the entire system reaches the actual production pressure required...

Embodiment 2

[0054] When measuring the viscosity of the oil-water two-phase mixed fluid after adding the additive (in the third high-temperature and high-pressure container 16) to the fluid in the actual production process, open the second injection pump 17, set a certain flow rate (this flow rate must be accurately controlled), and add the additive Inject the main pipeline 15 through the injection hole, make the additive mix with the flow in the main pipeline 15, and observe the readings of the differential pressure sensor and the pressure sensor at any time. Under the condition of high temperature and high pressure, the main fluid can be injected into the whole circulation mechanism by using the circulation injection pump and the pressure regulating pump first. After reaching the required pressure, set the heating temperature of the electric heating jacket 22 and operate the circulation mechanism to make the main fluid circulate in the circulation pipeline. , during the flow process, the ...

Embodiment 3

[0056] When measuring the viscosity of a two-phase oil-water two-phase mixed fluid (such as oil and water), the two fluids are respectively placed in the first high-temperature and high-pressure container 11 and the second high-temperature and high-pressure container 12, and the first control valve 51 and the second control valve 51 are opened. The control valve 52 and the third control valve 53 start the first injection pump 13 and the second injection pump 17 at the same time. By controlling the flow rates of the first injection pump 13 and the second injection pump 17, the two fluids can be controlled to contain each other in the main pipeline. The phase holdup rate is the flow rate ratio between the first injection pump 13 and the second injection pump 17. By setting the flow rate of the first injection pump 13, the total flow rate of the oil-water two-phase mixed fluid can be controlled, and the entire system can be controlled by the electric heating controller 21. tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com