Loading and hoisting integrated compression box

A technology of compression box and lifting frame, which is applied in the field of compression box, can solve the problems of difficult design of movable stuffing hopper, mutual interference of lifting hooks, reduction of movable stuffing hopper, etc., and solve the limitation of tipping angle and length direction , reduce the space occupied, the effect of ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

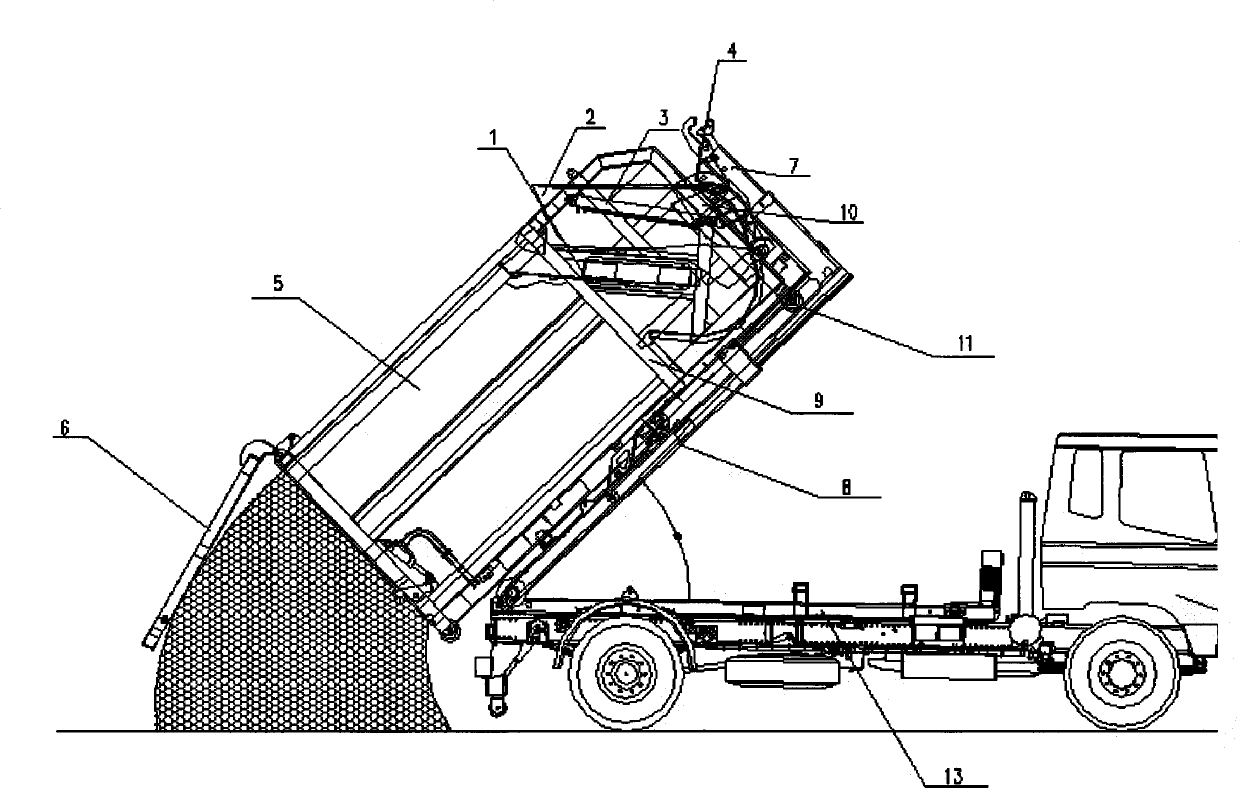

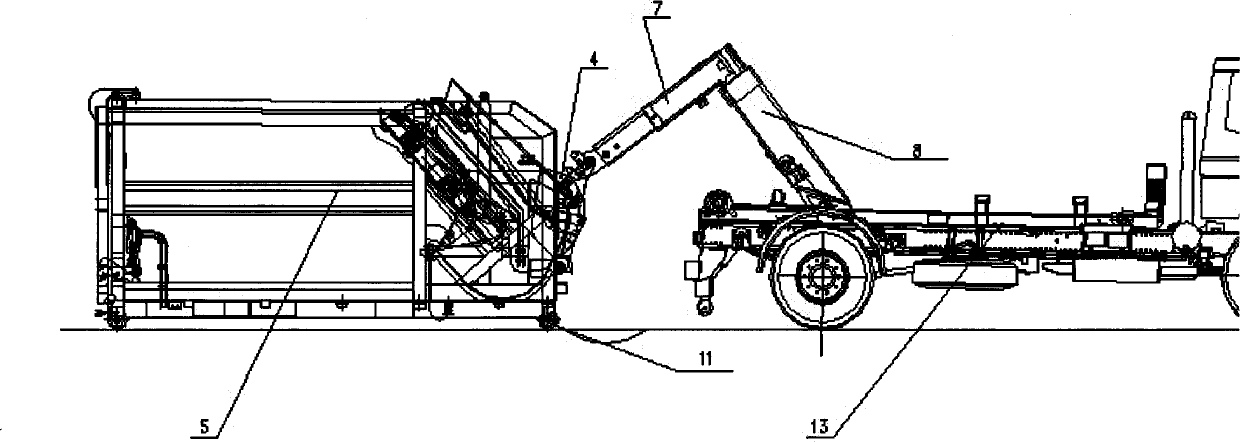

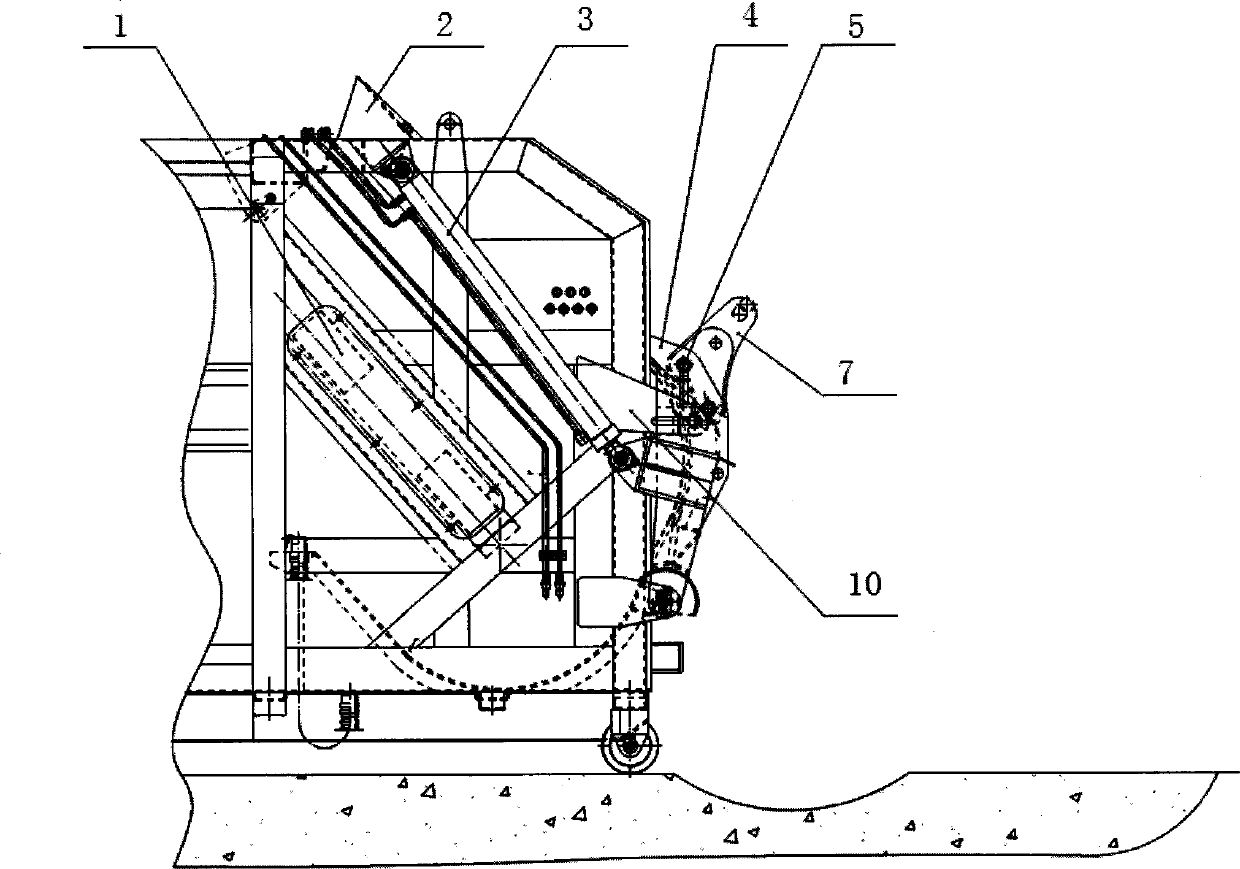

[0020] The present invention aims at reducing the tipping angle of the movable filler hopper in the existing technology, causing garbage to remain in the filler hopper, or reducing the size of the movable filler hopper in the length direction to avoid interference with the lifting hook, and at the same time To solve the problem of limiting the charging volume of the movable stuffing hopper, a compression box that integrates feeding and lifting is provided, such as Figure 1-3 Shown, comprise car body 8, be located at the car frame 12 on car body 8, box body 5 and be used for the jack that connects box body 5 and car frame 12, described jack includes lifting base 5 and jack A heavy frame 7, one end of the box body 5 is provided with a stuffer 1, an upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com