Low-noise circular saw web and preparation method thereof

A circular saw blade and low-noise technology, which is applied in the field of low-noise circular saw blades and its preparation, can solve problems such as premature optimization algorithms and inability to obtain results, and achieve the goal of improving global search capabilities, improving workers' physical and mental health, and being easy to implement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings.

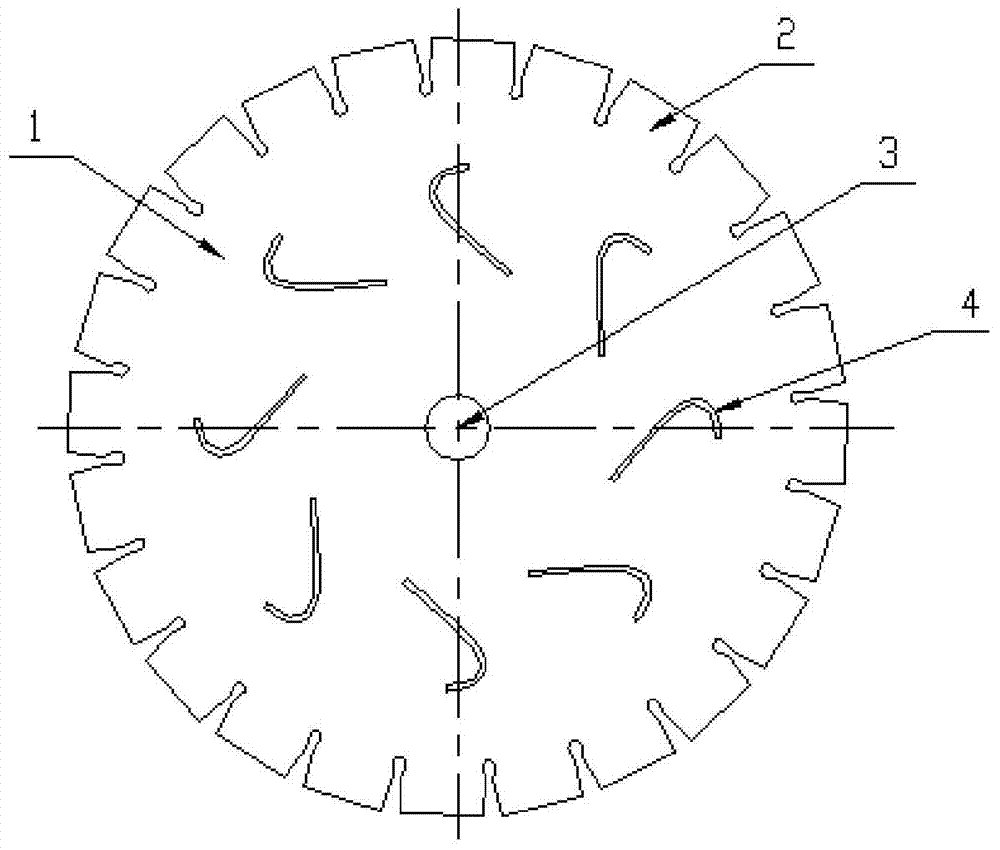

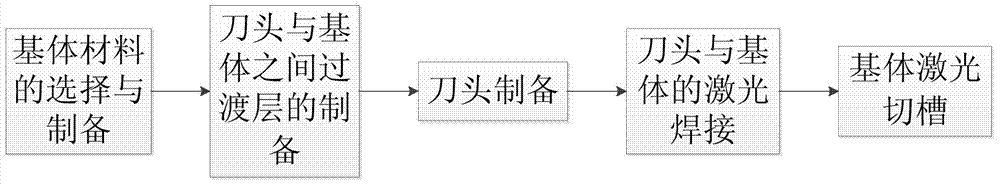

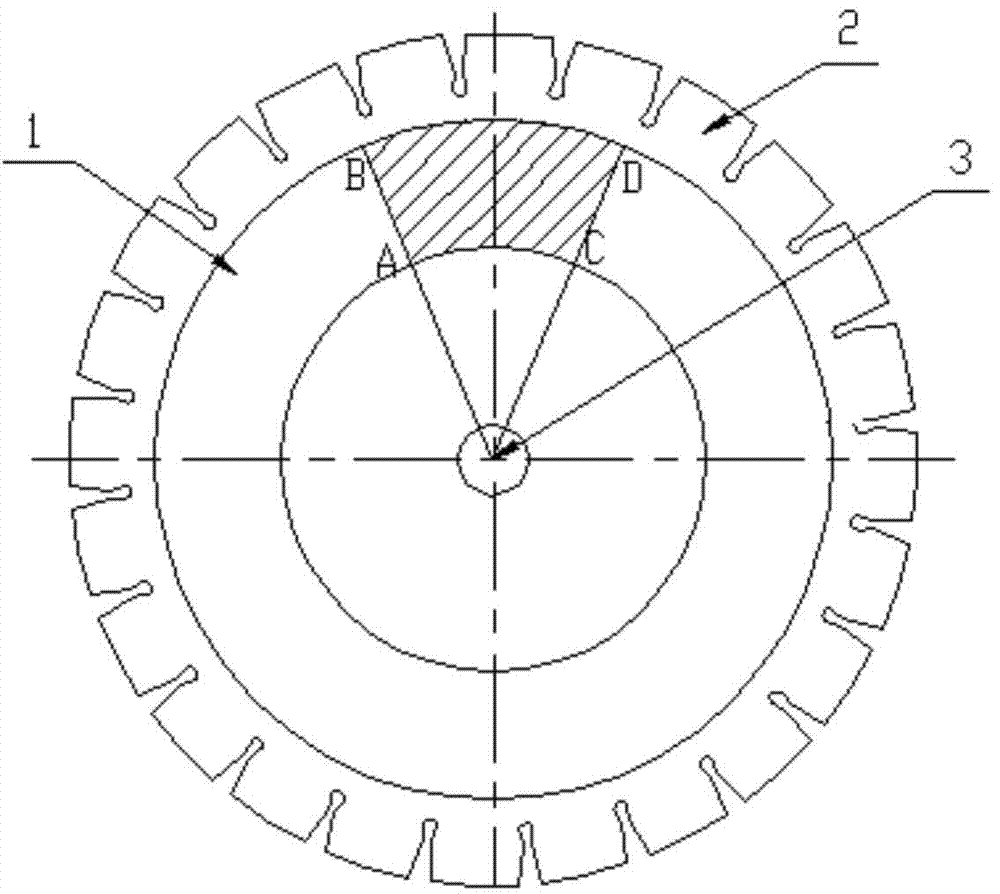

[0032] The low-noise circular saw blade designed by the present invention (referred to as circular saw blade, see figure 1 , 3 , 6 and 7), including the base body 1, the outer edge of the base body 1 is distributed with tooth-shaped segments 2, the center of the base body 1 is opened with a mounting hole 3, and the base body 1 between the mounting hole 3 and the tooth-shaped segment 2 is uniformly distributed in the circumferential direction There are curved grooves 4, which are characterized in that the curved grooves 4 evenly distributed in the circumferential direction of the base body 1 are NURBS curved grooves, and the curved grooves 4 are NURBS curved grooves 4 obtained by the optimized design of the genetic algorithm that introduces the improved simulated annealing mechanism.

[0033] The thickness of the circular saw blade in the pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com