Automatic marking machine

A technology of automatic scribing and scribing devices, applied in the field of construction machinery, can solve problems such as low efficiency, inability to realize automatic production, and large errors, and achieve the effects of reducing labor intensity, saving labor costs, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

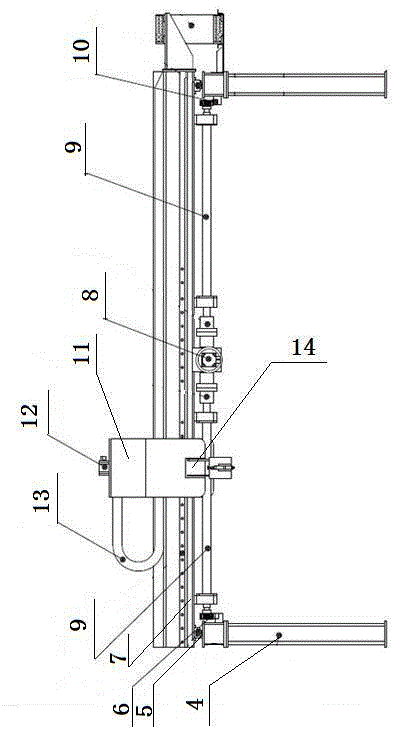

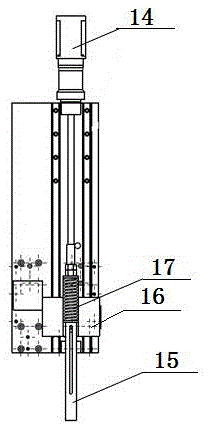

[0021] see figure 1 — Figure 4 , the automatic marking machine of the present invention is made up of three major parts of fixed base 1, walking system 2 and marking device 3, and described walking system 2 is installed on the fixed base 1, and described marking device 3 is installed on walking on system 2.

[0022] The above-mentioned fixed base 1 is a rectangular hollow beam installed and fixed on the column 4, and a linear guide rail 5 and a rack 6 are installed on the rectangular hollow beam.

[0023] The above-mentioned traveling system 2 includes an X-axis traveling assembly and a Y-axis traveling assembly; the described X-axis traveling assembly includes an X-axis traveling frame 7 and an X-axis servo motor 8 connected to transmission in sequence, an X-axis transmission device 9 and an X-axis driving assembly. The X-axis travel gear 10, the X-axis travel gear 10 meshes with the rack 6 on the fixed base 1, and the X-axis travel frame 7 also slides on the linear guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com