A welding platform for laser precision welding

A technology of precision welding and welding platform, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of difficult operation of electric soldering iron, time-consuming electric soldering iron, and high requirements for workers, so as to reduce the workload of workers and improve production efficiency. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in detail below in conjunction with accompanying drawing:

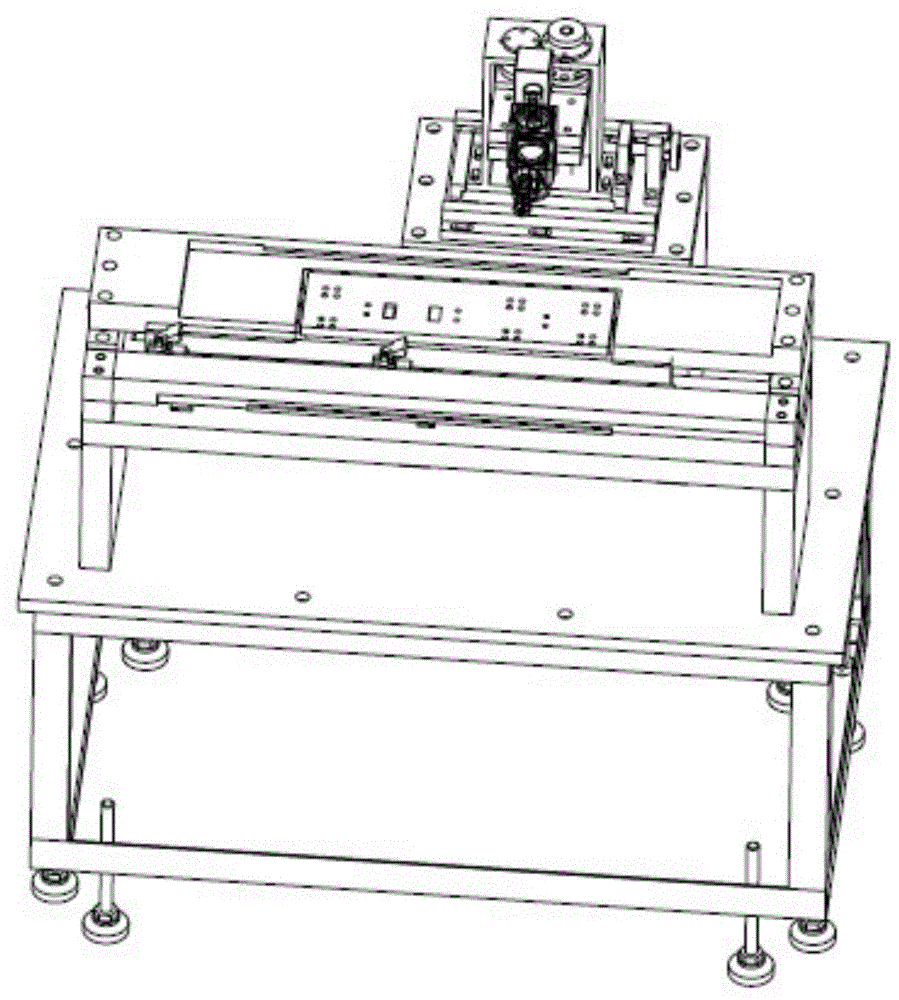

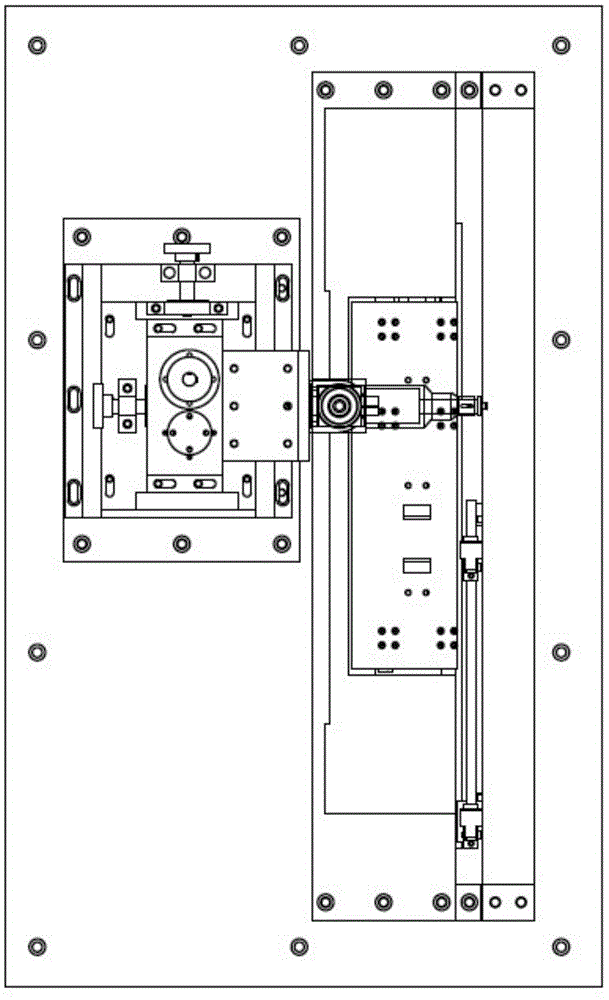

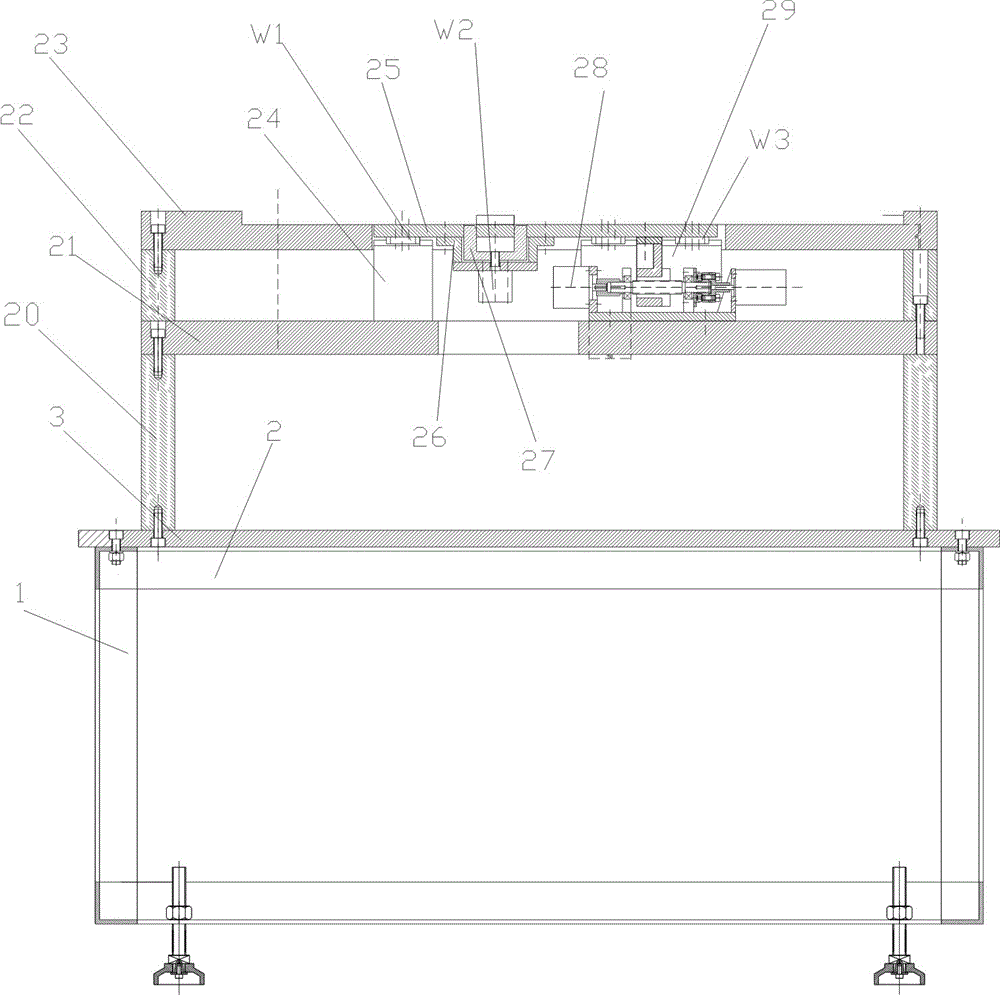

[0021] The invention provides a welding platform for laser precision welding, on which the laser welding operation of components can be carried out. The platform can be roughly divided into three parts: the frame part, the adjustment mechanism, and the movement mechanism; Laser head position, such as Figure 6 , Figure 7 shown. Before welding, because the position of different welding points of the jig changes, it is necessary to adjust the position of the laser head to make it in the best welding position. Adjust the screw rods A and B to realize the adjustment in the x and y directions, and the screw rod 12 realizes the adjustment in the Z direction of the laser head. The motion mechanism: realizes the automatic and precise movement of the fixture to ensure continuous production.

[0022] As shown in the figure: the welding platform for laser precision welding of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com