Combined biomass breaking machine

A biomass and crusher technology, which is applied in the fields of papermaking development, gasification, and biomass power generation, can solve the problems of poor crushing effect of flexible biomass raw materials, low crushing stability of hammer mill crushers, and complicated crushing process. The effect of convenient equipment maintenance and repair, simple structure and simple replacement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

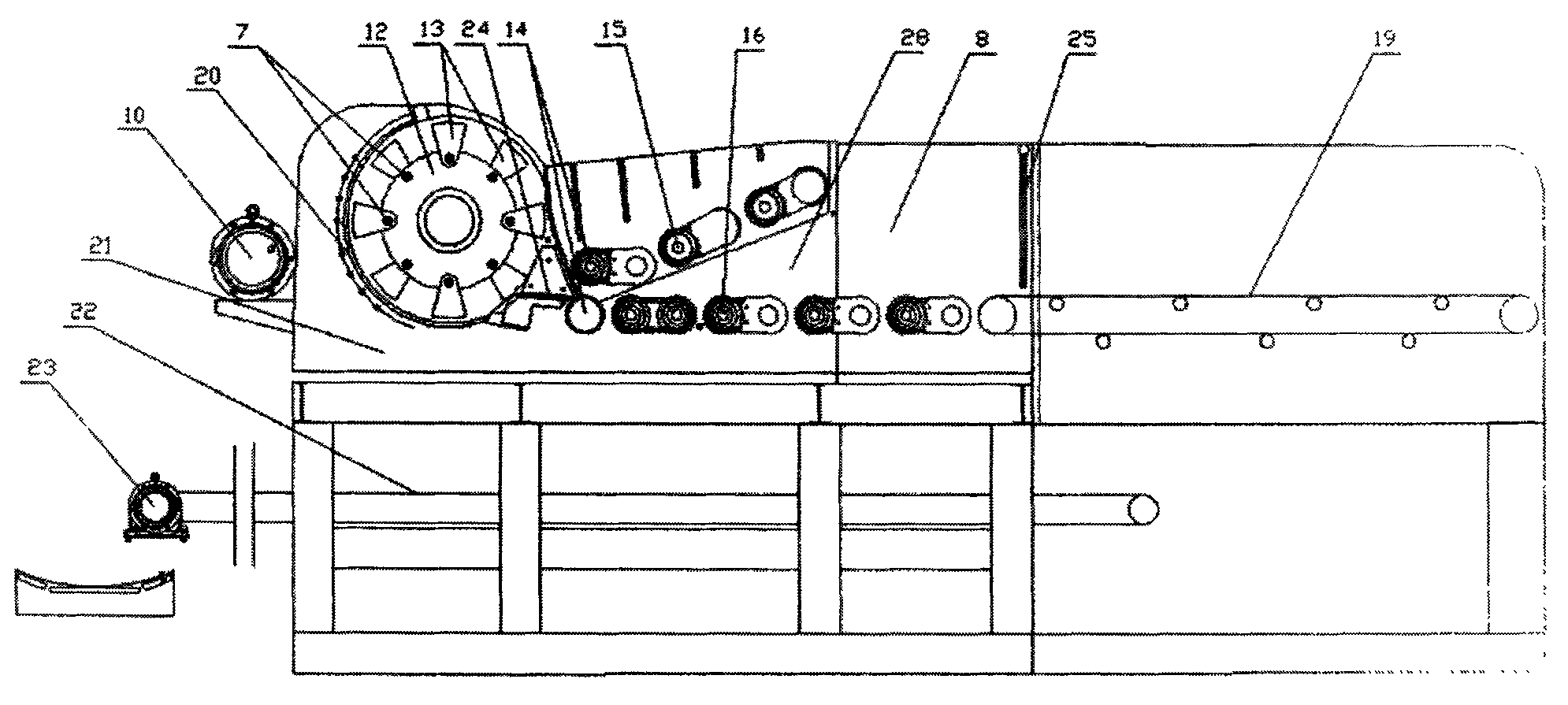

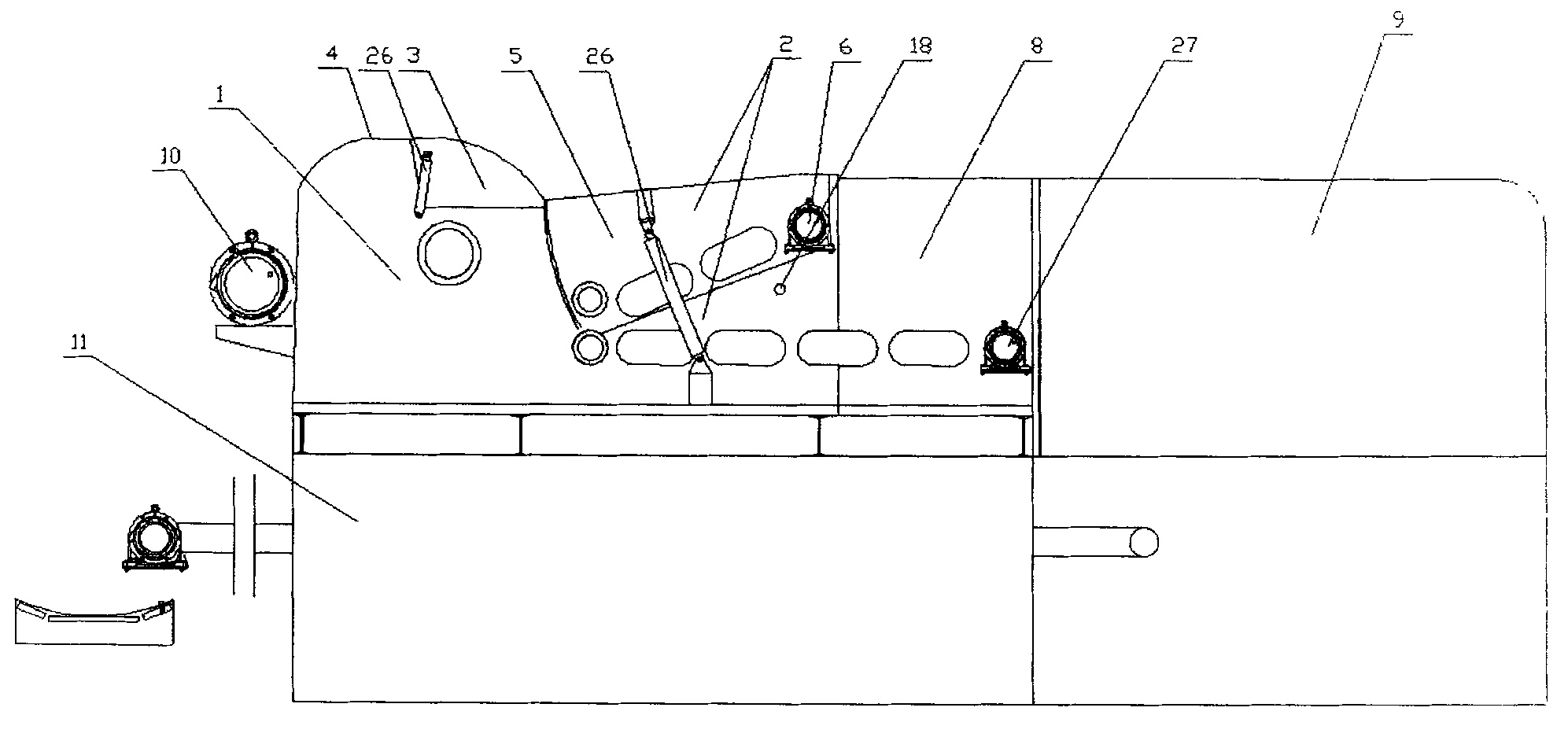

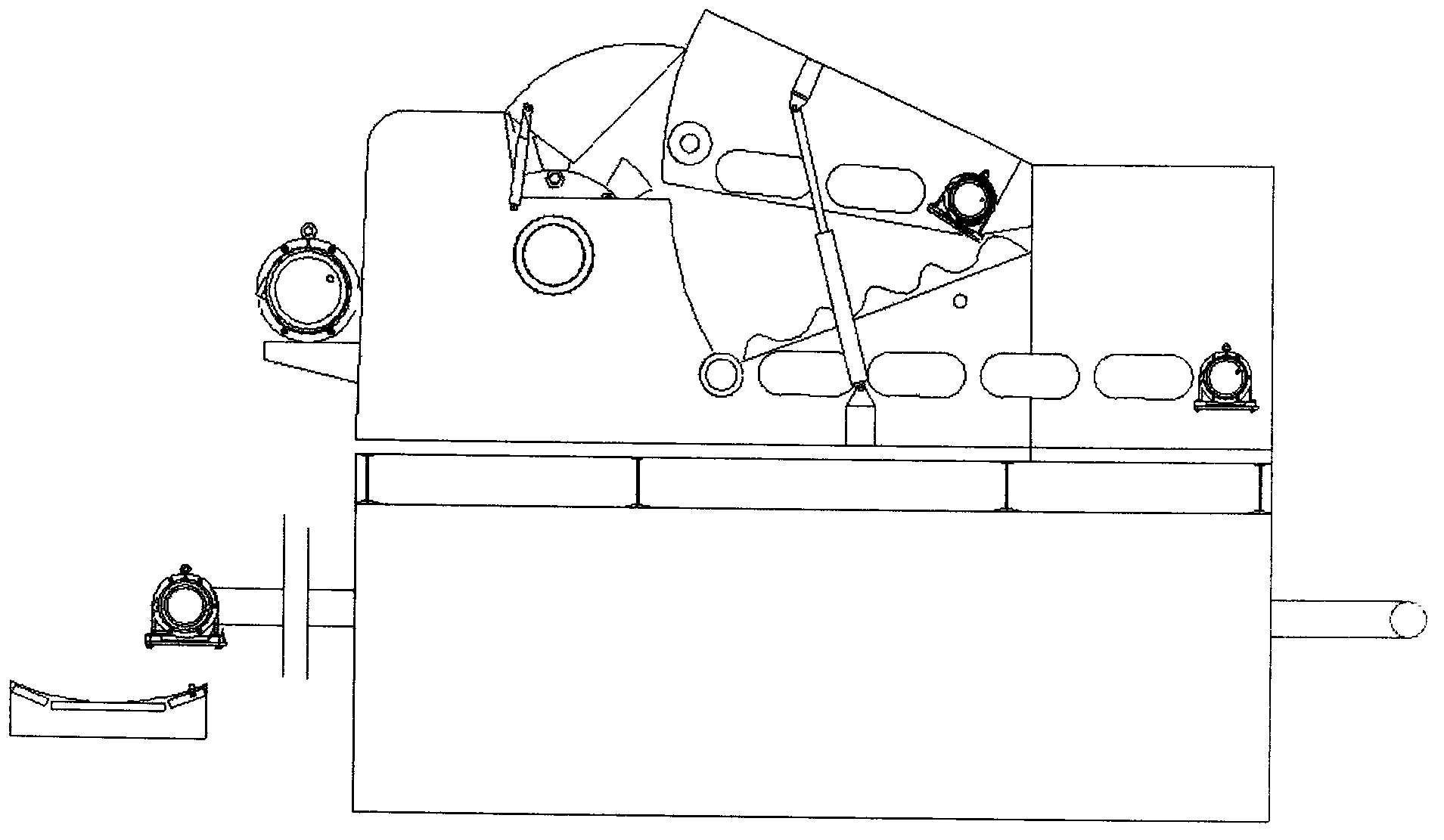

[0027] The specific implementation of a composite biomass crusher will be described in detail below with reference to the drawings.

[0028] Such as Figure 1 to 6 As shown, a composite biomass crusher includes a feeding device 9, a discharging device 11, a crushing device 1, and a feeding device 2. The crushing device 1 includes a rotor main shaft 17, a rotor cutter head 12, and a flying knife 13. , Knife pin 7, filter screen 20, rotor cutter head 12 and other gaps are arranged and fixed on the rotor spindle 17, multiple groups of flying knives 13 are connected to the rotor cutter head 12 through the knife pins 7, and the flying knives 13 are on the adjacent rotor cutter head 12. A pin sleeve 29 is added to limit the position. Driven by the rotor power device 10, the rotor cutter head 12 rotates at a high speed, and the flying knife 13 rotates at a high speed with the axis of the rotor main shaft 17 as the center to generate centrifugal force. The flying knife 13 and the filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com