Powder mixing technology

A mixing process and powder technology, applied in mixers, mixing methods, dissolution and other directions, can solve the problems of long mixing time, low production efficiency, low equipment utilization, etc., and achieve the effect of uniform and sufficient material mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

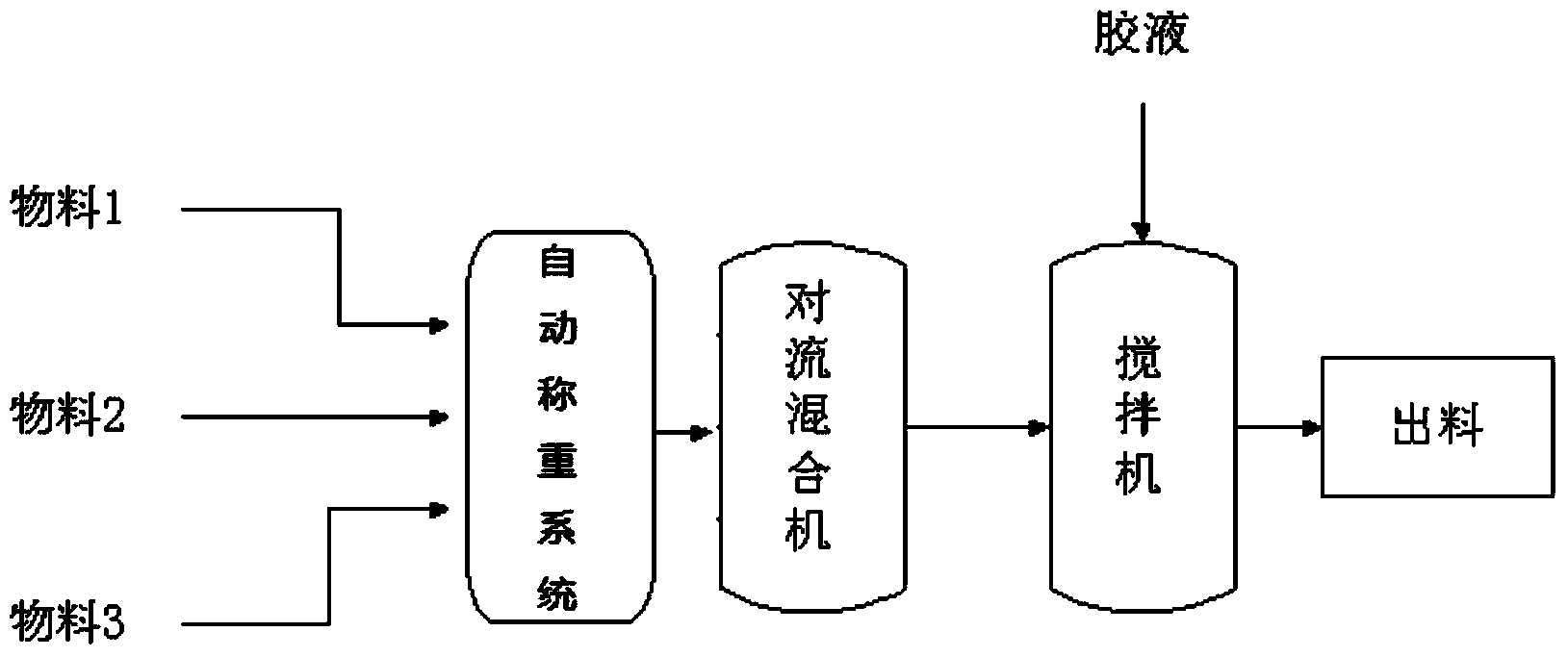

[0018] Such as figure 1 As shown, a powder mixing process, the powder is first pre-mixed by a convection mixer before mixing, and the specific steps are as follows:

[0019] (1) Weigh all kinds of materials through the automatic weighing system;

[0020] (2) The main material in the material is firstly circulated in the convection mixer;

[0021] (3) According to the requirements, add other different materials in the convection mixer for convection mixing;

[0022] (4) Add colloid to the mixed material after coming out of the mixer and stir in the mixer;

[0023] (5) Discharge after mixing.

[0024] A convective mixer in the aforesaid powder mixing process, such as figure 2 As shown: it includes a mixing tank 1 and a C-shaped feeding pipeline 4 communicating with both sides of the mixing tank 1. The mixing tank 1 includes a horizontal tank-shaped base 2 and a lower funnel-shaped extension 3. The mouth of the C-shaped feeding pipeline 4 extends into the tank with a convec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com