Automatic filtration injector

An automatic filter and syringe technology, applied in the field of syringes, can solve the problems of bacteria or virus pollution, inconvenient clinical operation, etc., and achieve the effect of low cost, avoiding bacteria and virus pollution, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

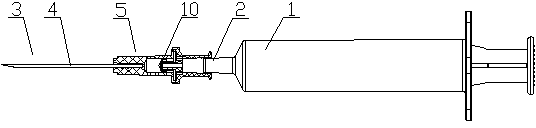

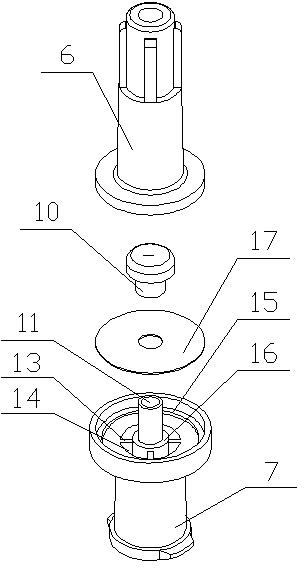

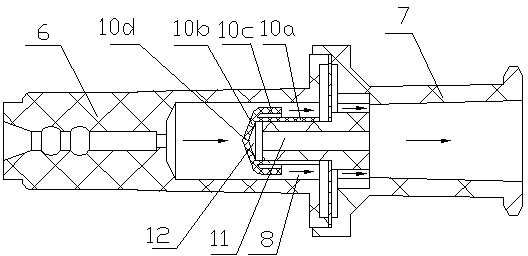

[0016] from Figure 1-Figure 4 As can be seen from the above, an automatic filtering syringe includes a syringe 1 and an injection needle 3. The injection needle 3 consists of a needle tube 4 and a needle seat 5. The needle tube 4 is installed at the front end of the upper needle seat 6 and the rear of the lower needle seat 7. The end is connected to the cone head 2 of the syringe 1. The front end of the lower needle seat 7 is combined with the upper needle seat 6 to form a suction inlet 8 and an injection outlet 9. A check valve 10 is installed on the lower needle seat 7. The suction direction of the suction inlet and the injection direction of the injection outlet are opened, and a filter is attached to the suction inlet 8 .

[0017] like figure 2 , image 3 and Figure 4 As shown, the middle part of the upper end of the lower needle seat 7 extends upward to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com