Empty bottle inspection

A technology for inspecting devices and bottles, which is applied in the field of inspecting devices for monitoring bottles or similar containers, and can solve the problems of product producers or system manufacturers, such as loss, unprofitable downtime, and failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

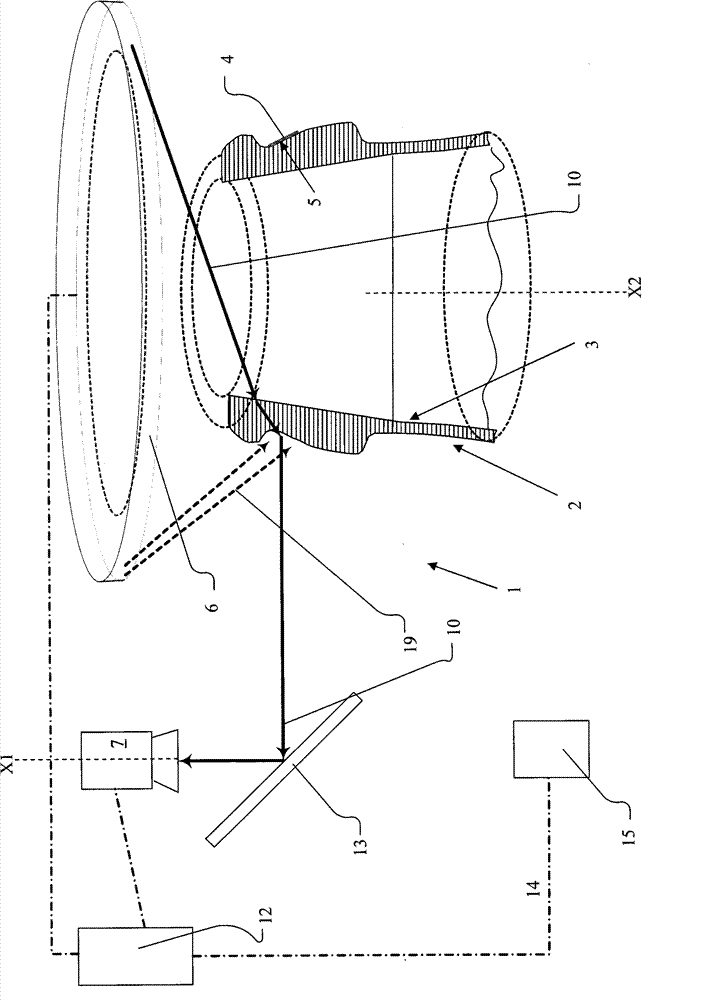

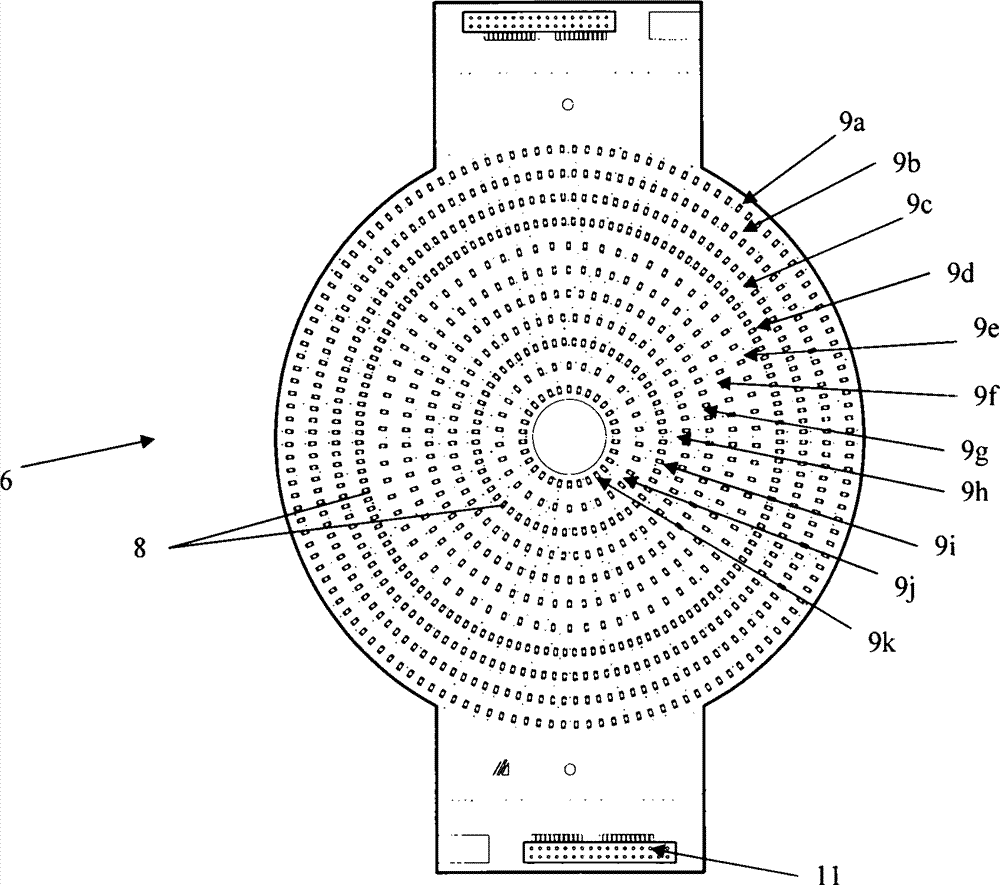

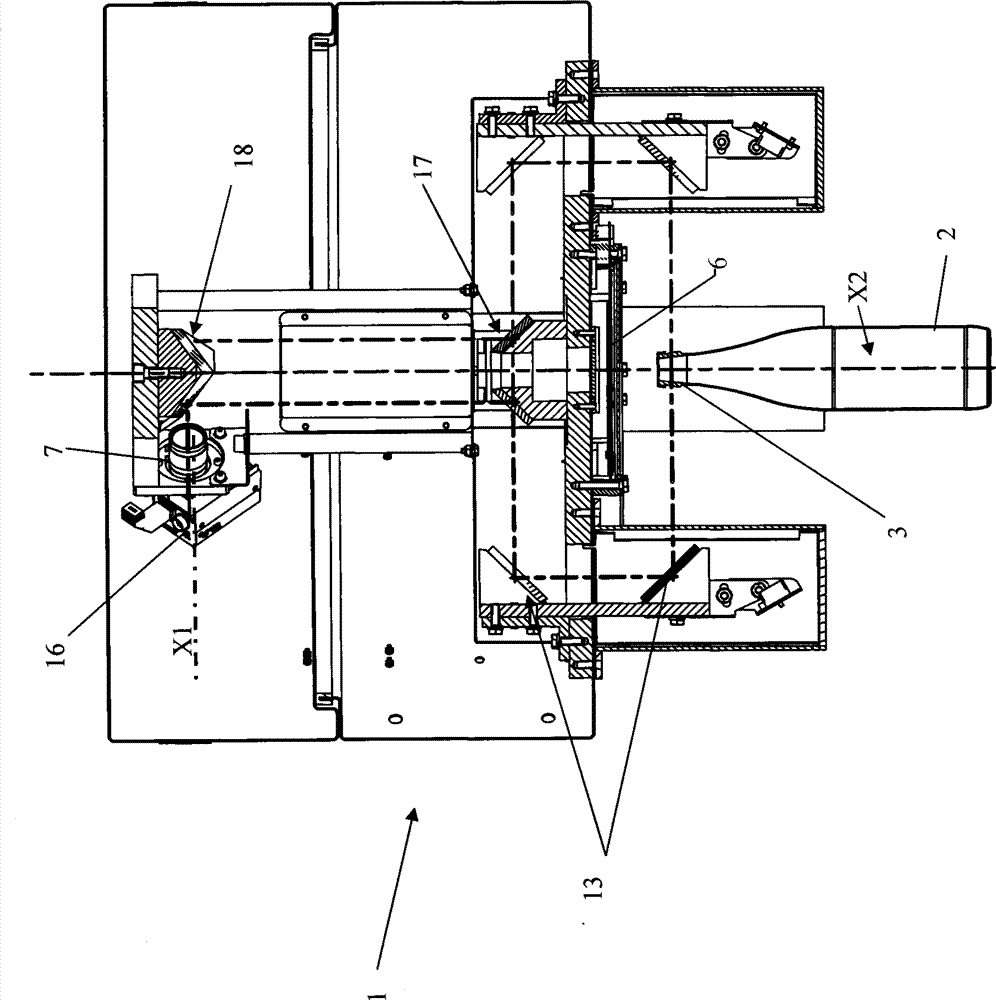

[0023] In the different figures, the same parts are always indicated with the same reference numerals and are therefore always described only once. exist figure 1 and image 3 In , the beam paths of the mirror images are indicated using dotted lines and no reference numerals are provided separately.

[0024] figure 1 Shown is an inspection device 1 for monitoring bottles 2 or similar containers. Hereinafter, bottle 2 or similar container is generally designated as bottle 2 . The bottle 2 can be made of transparent or translucent material, preferably glass, or translucent plastic, such as PET. As a few examples, the material or glass of the bottle may eg be blue, green or brown.

[0025] Bottle 2 has a bottom and side walls. The mouth 3 is arranged opposite to the bottom. Using the inspection device 1 , preferably the mouth 3 of the bottle 2 is inspected, preferably after it has been cleaned of eg contaminants, such as scale 4 .

[0026] In this respect, this can also b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com