A process method for dipping mucus on grid surface and solidifying polar plate

A technology of plate curing and process method, applied in the direction of lead-acid battery electrodes, etc., can solve the problems of reduced porosity of lead paste, affecting the consistency of plate curing, and short battery life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

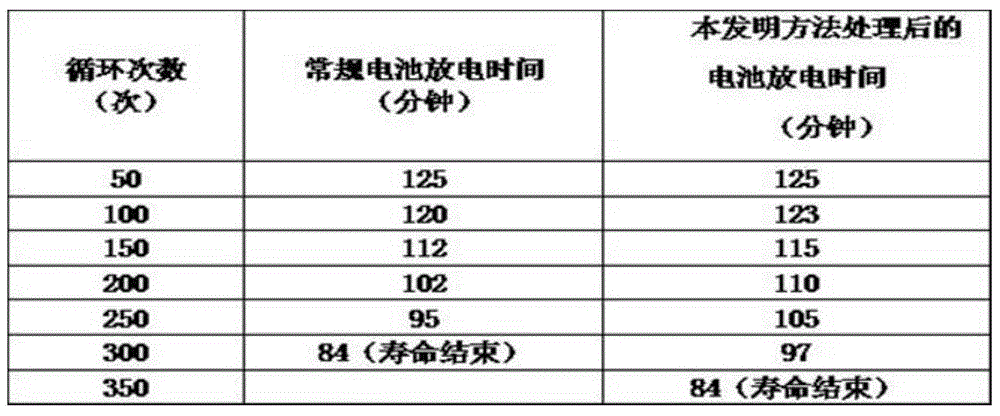

Examples

Embodiment 1

[0012] Embodiment 1: adopt the mode of grid dipping mucus to improve, and step is: pure water is heated to 45 ℃, then adds sodium perborate, antimony trioxide to dissolve, obtains solution (hereinafter referred to as liquid state), every 100 kilograms of pure Water, add 8 kg of sodium perborate, add 3 kg of antimony trioxide, keep the temperature of the solution at 45°C, immerse the grid for 2 seconds, then dry naturally for 20 minutes, the conductivity of the pure water is ≤2μs / cm ;

[0013] Plate curing process: apply wet lead paste on the above-mentioned dry grid according to the conventional method, and then transport the plate coated with wet edge paste to a humidified and heated curing room for curing. Moisturizing stage: the temperature is 45°C , the humidity is 97%, the moisture of the lead paste is 8%, and the time is 15 hours; the oxidation stage of the lead paste: the moisture of the lead paste is controlled at 2%, the temperature is controlled at 60°C, the humidity...

Embodiment 2

[0014] Embodiment 2: improve by adopting the mode of grid immersion mucus, step is: pure water is heated to 50 ℃, then adds sodium perborate, antimony trioxide to dissolve, obtains solution (hereinafter referred to as liquid state), every 100 kilograms of pure Water, add 11 kg of sodium perborate, add 4 kg of antimony trioxide, keep the solution temperature at 50°C, immerse the grid for 3 seconds, then dry naturally for 30 minutes, the conductivity of the pure water is ≤2μs / cm ;

[0015] Plate curing process: apply wet lead paste on the above-mentioned dry grid according to the conventional method, and then transport the plate coated with wet edge paste to a humidified and heated curing room for curing. Moisturizing stage: the temperature is 50°C , the humidity is 98%, the moisture of the lead paste is 9%, and the time is 19 hours; the oxidation stage of the lead paste: the moisture of the lead paste is controlled at 3%, the temperature is controlled at 62°C, the humidity is 9...

Embodiment 3

[0016] Embodiment 3 is improved by dipping the grid into mucus. The steps are: pure water is heated to 55° C., then sodium perborate and antimony trioxide are added to dissolve to obtain a solution (hereinafter referred to as liquid state), and every 100 kilograms of pure water , add 15 kg of sodium perborate, add 5 kg of antimony trioxide, keep the temperature of the solution at 55°C, immerse the grid for 5 seconds, and then dry it naturally for 40 minutes, the conductivity of the pure water is ≤2 μs / cm;

[0017] Plate curing process: apply wet lead paste on the above-mentioned dry grid according to the conventional method, and then transport the plate coated with wet edge paste to a humidified and heated curing room for curing. Moisturizing stage: the temperature is 55°C , the humidity is 100%, the moisture of the lead paste is 11%, and the time is 24 hours; the oxidation stage of the lead paste: the moisture of the lead paste is controlled at 5%, the temperature is controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com