Transparent conductive substrate and touch panel having the same

A transparent, substrate technology, applied to the conductive layer on the insulating carrier, the input/output process of data processing, optics, etc., to achieve the effect of low manufacturing cost, fast coating speed, and excellent productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

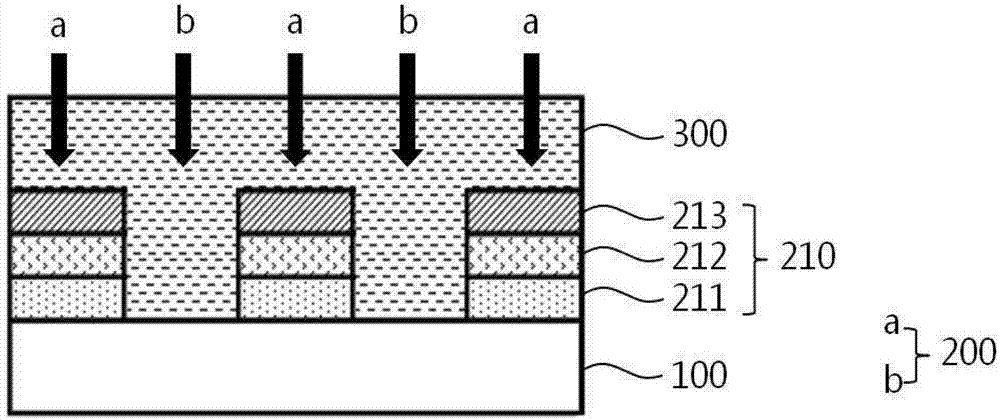

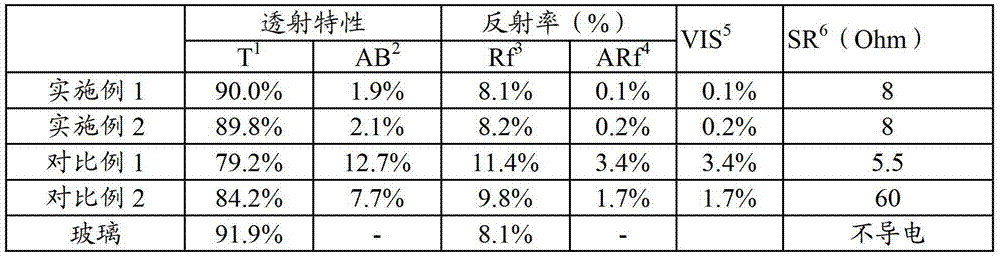

[0052] The transparent conductive substrate according to Example 1 includes a glass substrate on which is formed a glass substrate having a thickness of 31 nm and made of Nb 2 o 5 The first film made, on the first film, a planarization layer with a thickness of 5 nm and made of ZnO is formed, on the planarization layer, a metal film with a thickness of 10 nm and made of Ag is formed, on the metal film, a metal film with An anti-oxidation layer with a thickness of 5 nm and made of ZnO, and an anti-oxidation layer with a thickness of 31 nm and made of Nb 2 o 5 A second film was produced and a resin layer having a thickness of 5 μm was formed on the second film. Here, the resin layer was formed using Samyang EMS SOC3006U resin.

Embodiment 2

[0054] Except for the first film by Ta 2 o 5 made and has a thickness of 35nm, and the second film is made of Ta 2 o 5 The transparent conductive substrate according to Example 2 has the same configuration as Example 1 except that it is made and has a thickness of 36 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com