General type cavity wet-type leakproofness leakage testing workbench

A wet sealing, general-purpose technology, applied in the direction of liquid tightness measurement using liquid/vacuum degree, and detecting the appearance of fluid at the leakage point, etc., can solve problems such as casting defects, poor accuracy, and low work efficiency, and achieve The effect of low production cost, strong versatility and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

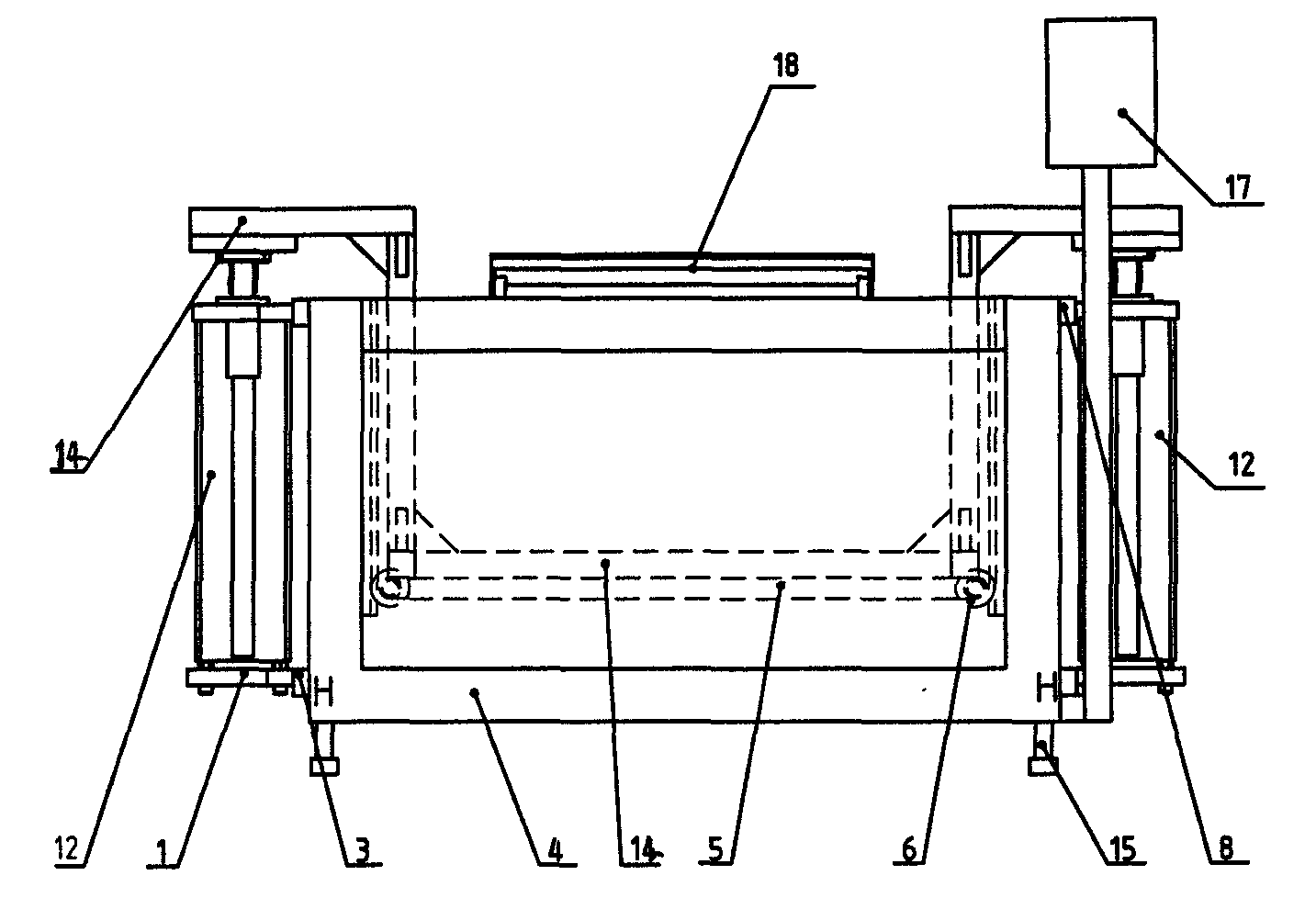

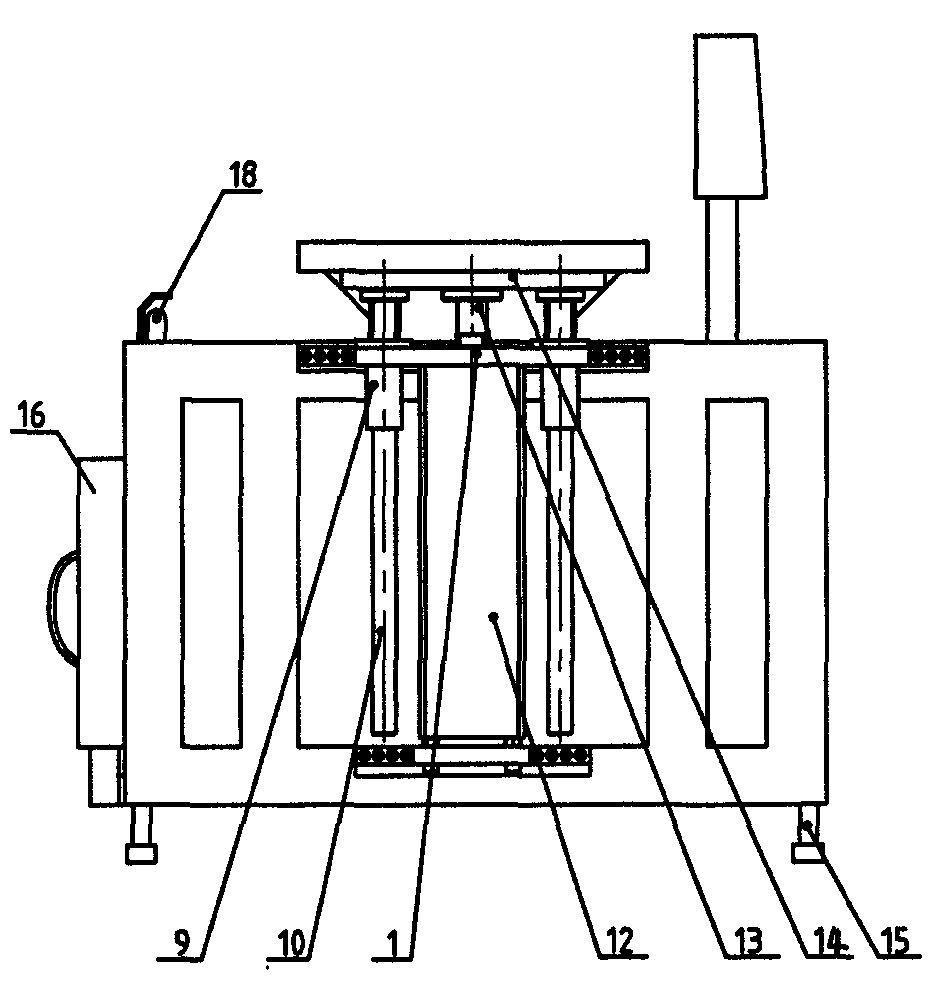

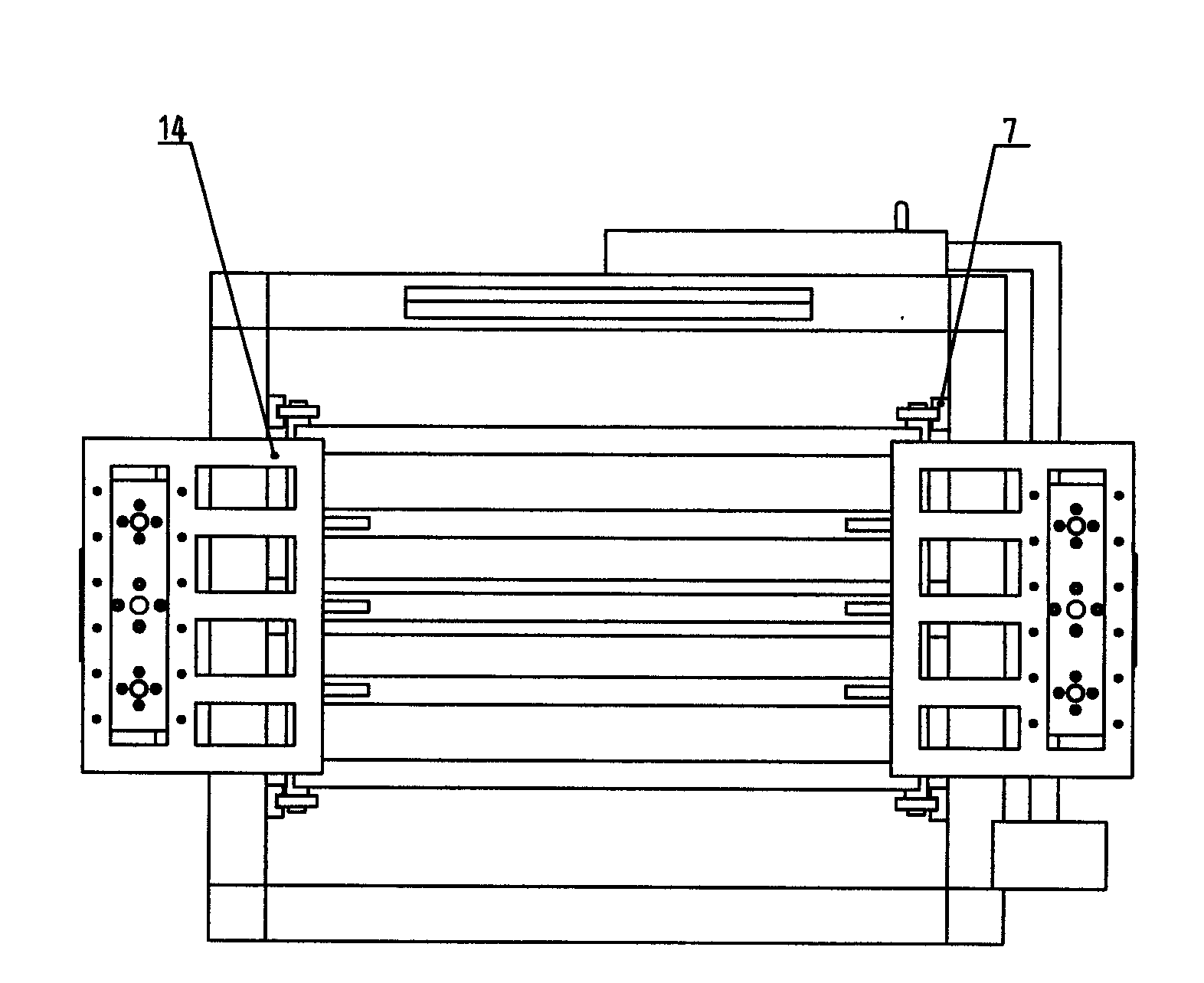

[0011] refer to Figure 1 to Figure 4 It can be seen that the general-purpose cavity wet leak test workbench of the present invention comprises a casing 4 (i.e. a water tank), and cylinders 12 (standard pull rods) are equipped with cylinder mounting seats 1 on both outer sides of the casing 4. In the case 4, a tray 14 (bench type concave type) is installed on the piston rod of the cylinder 12; a trachea connector 18 (quick-plug type, containing trachea) is installed on the rear side of the case 4 connected with the air compressor), centralize the air pipes coming out of the microcomputer control cabinet 16, and perform action distribution according to different product fixtures. The air pipe joint is designed as a quick-plug type. , can achieve the purpose of quick replacement and improve production efficiency.

[0012] On the cylinder mounting seat 1 (through the linear guide rod bearing 9) guide rods 10 are installed, and the guide rods 10 are located at both sides of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com