Oil well broken rod blowout preventer

A blowout preventer and broken rod technology, which is used in wellbore/well components, earthwork drilling, sealing/packaging, etc. Improves life and prevents wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

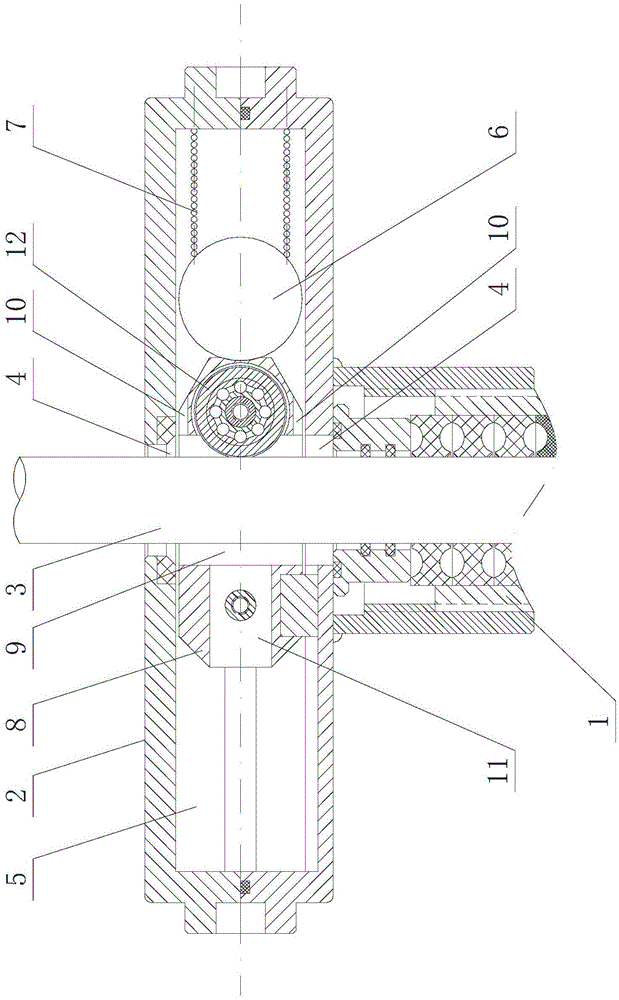

[0022] refer to figure 1 It is the first embodiment of the oil well broken rod blowout prevention device of the present invention. The oil well broken rod blowout preventer includes a casing 2 docked with the packing box 1, and the casing 2 is provided with a through hole 4 for the light rod 3 to pass through. , the housing 2 is provided with a plugging cavity 5 communicating with the through hole 4, and the plugging cavity 5 is provided with a steel ball 6 for plugging the through hole 4, and the plugging cavity 5 behind the steel ball 6 is A first elastic member 7 that ejects the steel ball 6 is provided inside, and a control device that prevents the steel ball 6 from contacting the polished rod 3 when the polished rod 3 is in normal operation is provided inside the housing 2

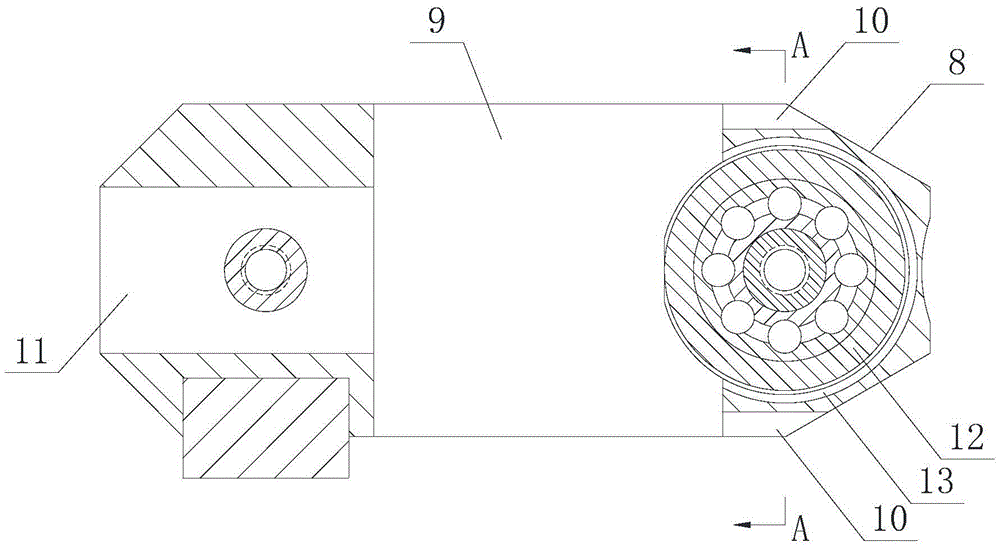

[0023] Such as figure 2 As shown, the control device includes an anti-wear block 8 arranged between the polished rod 3 and the steel ball 6, the anti-wear block 8 is provided with a middle hole 9 fo...

Embodiment 2

[0026] refer to Figure 4 The difference from Embodiment 1 is that the structure of the control device is different. The lower part of the through hole 4 is provided with a sealing ring 19 to prevent oil leakage. The push rod 21 of the boss 20, the push rod 21 is arranged between the steel ball 6 and the first elastic member 7, a step 22 is provided in the sealing cavity 5, the push rod 21, the boss 20, the step 22 and the side wall of the sealing chamber 5 enclose a closed pressure chamber 23, and the housing 2 is provided with a pressure channel 24 that communicates the pressure chamber 23 with the through hole 4 below the sealing ring 19, and the first elastic member 7 compresses The thrust produced on the push rod 21 is equal to the thrust generated by the oil entering the pressure chamber 23 on the boss 20. When the first elastic member 7 is compressed, the distance between the front end of the push rod 21 and the polished rod 3 is greater than the diameter of the steel b...

Embodiment 3

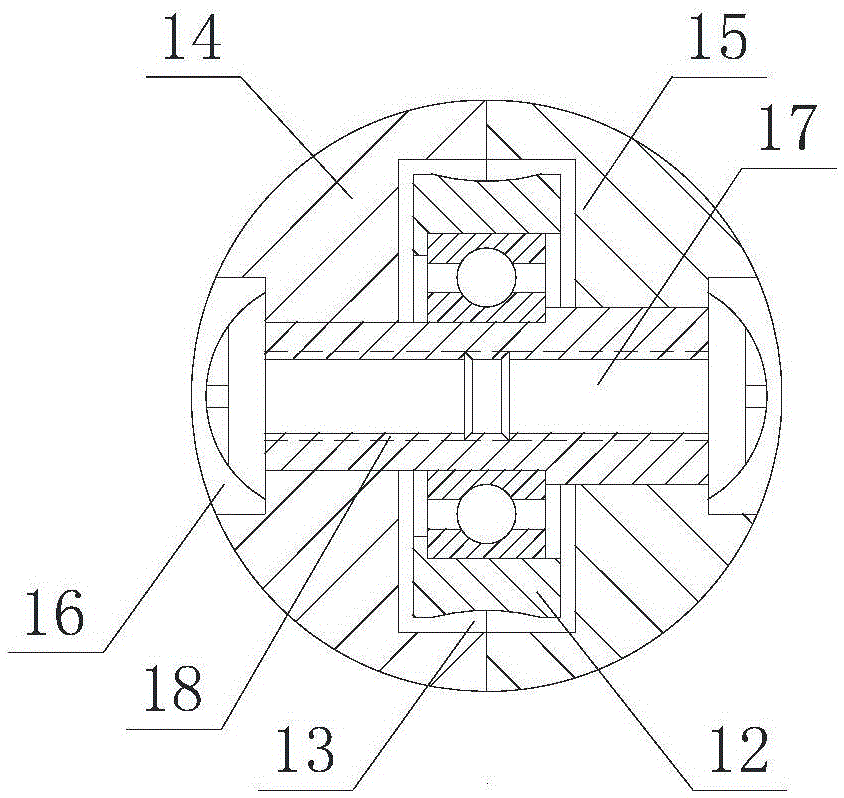

[0030] Such as Figure 5 As shown, the control device includes a control cavity 25 arranged in the housing 2 and communicated with the through hole 4, a pin 26 pierced into the blocking cavity 5, and a control pin 26 set in the control cavity 25 to withdraw from the blocking cavity 5. The trigger mechanism, such as Image 6 As shown, the pin 26 is arranged in the stepped hole 27 between the control chamber 25 and the blocking chamber 5, the smaller end of the stepped hole 27 communicates with the blocking chamber 5, and the stepped hole 27 has a larger opening One end of the pin communicates with the control cavity 25, and the middle part of the pin 26 is provided with a positioning eaves 28, and a second elastic member 29 is provided between the positioning eaves 28 and the steps in the stepped hole 27.

[0031] Such as Figure 5 As shown, the trigger mechanism includes a lever 30 arranged in the control cavity 25 , a second roller 31 arranged at one end of the lever 30 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com